In the world of round bottle packaging, achieving zero wobble and perfect alignment is crucial for a professional and appealing final product. This is precisely where tabletop labelers have emerged as the dominant force.

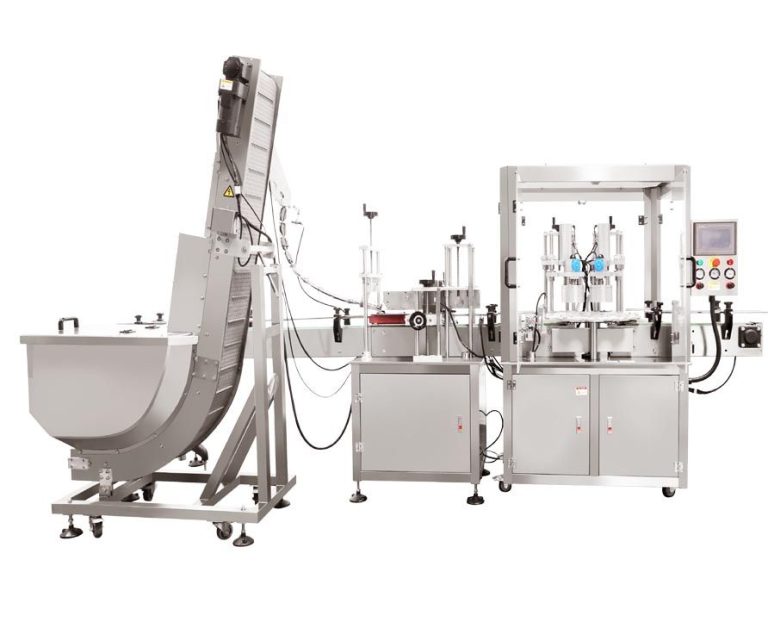

Tabletop labelers are engineered with precision and accuracy in mind. Their advanced mechanisms and intelligent control systems ensure that as labels are applied to round bottles, there is no instability or deviation. The result is a seamless and flawlessly aligned label that enhances the aesthetic appeal and marketability of the product.

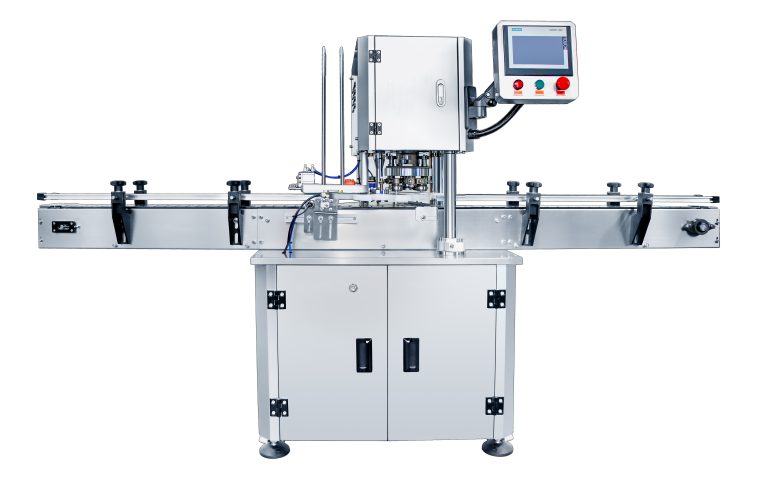

The compact design of tabletop labelers is another factor contributing to their dominance. They fit neatly into small workspaces, making them accessible and convenient for businesses of all sizes. Despite their size, they pack a punch in terms of performance.

These labelers are equipped with state-of-the-art sensors that detect the shape and size of round bottles in real-time. This allows for immediate adjustments and ensures that the label is applied precisely where it should be, every single time.

The speed at which tabletop labelers operate is also impressive. They can handle a large volume of round bottles in a short period, maintaining the quality and alignment without compromise.

Moreover, their ease of use and low maintenance requirements make them a preferred choice for packaging operations. Operators can quickly master the operation, and the machines require minimal upkeep to keep functioning optimally.

In conclusion, the ability of tabletop labelers to deliver zero wobble and perfect alignment, combined with their compact size, advanced technology, and user-friendly features, is why they have taken the lead in round bottle packaging. They are the go-to solution for businesses seeking efficiency, quality, and visual perfection in their packaging processes.