Table of Contents

Introduction

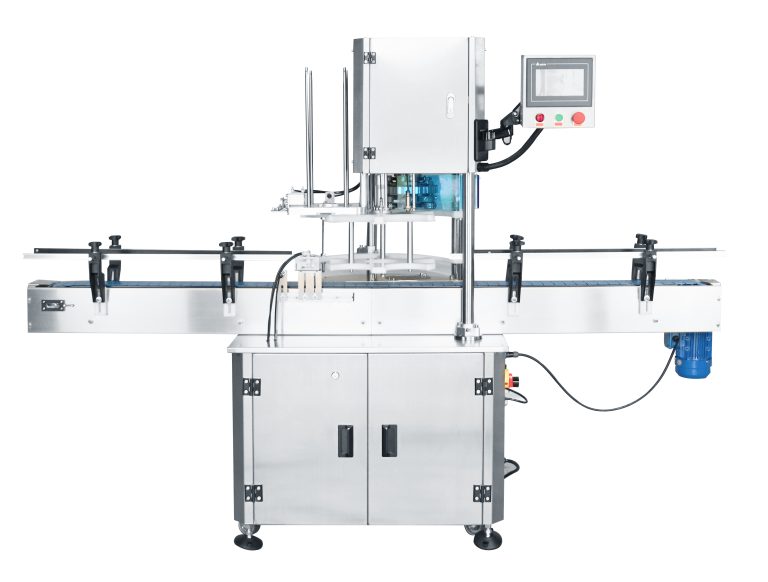

The chili sauce industry is a vibrant and competitive one, with consumers constantly seeking high – quality, flavorful products. However, packaging chili sauce in glass jars comes with its own set of challenges. Semi – auto chili sauce glass jar vacuum capping machines have emerged as a practical solution to these packaging hurdles, offering a range of benefits that streamline the production process and enhance the final product.

Challenge 1: Maintaining Product Freshness

The Problem

Chili sauce is a perishable product that can quickly lose its flavor, color, and texture when exposed to air. Oxygen in the air causes oxidation, which can lead to the development of off – flavors and the degradation of the sauce’s quality. Traditional capping methods may not effectively remove the air from the jar, leaving the chili sauce vulnerable to spoilage.

The Solution

Semi – auto vacuum capping machines address this issue by creating a vacuum inside the glass jar before sealing. By removing the majority of the air, the machines significantly reduce the risk of oxidation. This means that the chili sauce retains its original taste, aroma, and vibrant color for a much longer period. For example, a well – vacuum – sealed jar of chili sauce can stay fresh on the shelf for several months, ensuring that consumers receive a product that meets their expectations.

Challenge 2: Preventing Contamination

The Problem

Contamination is a major concern in the food industry, and chili sauce is no exception. Microorganisms such as bacteria, mold, and yeast can thrive in the moist environment of chili sauce, especially if the jar is not properly sealed. This can lead to product spoilage and pose a health risk to consumers.

The Solution

The vacuum capping process provided by semi – auto machines helps to create a barrier against contamination. By removing the air, the machines also eliminate a significant portion of the potential sources of microorganisms. Additionally, the tight seal created by the machine prevents external contaminants from entering the jar. This ensures that the chili sauce remains safe and hygienic throughout its shelf life.

Challenge 3: Ensuring Consistent Sealing Quality

The Problem

In manual capping processes, it can be difficult to achieve consistent sealing quality. Variations in operator technique, such as the amount of pressure applied or the alignment of the cap, can result in uneven seals. This can lead to leakage, which not only affects the product’s appearance but also increases the risk of spoilage.

The Solution

Semi – auto vacuum capping machines are designed to provide consistent sealing results. They use precise mechanisms to apply the right amount of pressure and ensure proper alignment of the cap on the jar. This means that every jar is sealed to the same high standard, regardless of the operator. As a result, the risk of leakage is minimized, and the overall quality of the packaged product is improved.

Challenge 4: Meeting Production Demands

The Problem

As the demand for chili sauce grows, manufacturers need to increase their production capacity. Manual capping is a time – consuming and labor – intensive process that may not be able to keep up with the pace of production. This can lead to bottlenecks in the production line and delays in getting products to market.

The Solution

Semi – auto vacuum capping machines offer a more efficient alternative to manual capping. While they are not fully automated, they still significantly reduce the time and effort required for the capping process. Operators can place the jars on the machine, and the machine will quickly create the vacuum and seal the jars. This allows manufacturers to increase their production output without sacrificing quality, helping them to meet the growing demand for their products.

Challenge 5: Adapting to Different Jar Sizes

The Problem

Chili sauce manufacturers often produce their products in a variety of glass jar sizes to meet different market needs. Using a single capping method for all jar sizes can be challenging, as different jars may require different sealing techniques and pressures.

The Solution

Semi – auto vacuum capping machines are designed to be flexible and can easily adapt to different jar sizes. Operators can make simple adjustments to the machine settings to accommodate jars of various heights, diameters, and shapes. This means that manufacturers can switch between different product lines quickly and efficiently, without having to invest in multiple capping machines.

Conclusion

Semi – auto chili sauce glass jar vacuum capping machines are a valuable asset for chili sauce manufacturers. They effectively solve the packaging challenges associated with chili sauce, from maintaining freshness and preventing contamination to ensuring consistent sealing quality and meeting production demands. By investing in these machines, manufacturers can improve the quality of their products, increase their production efficiency, and ultimately gain a competitive edge in the market.