Table of Contents

Benefits of Using an Automatic Sheep Milk Cheese Tin Can Press Capping Machine

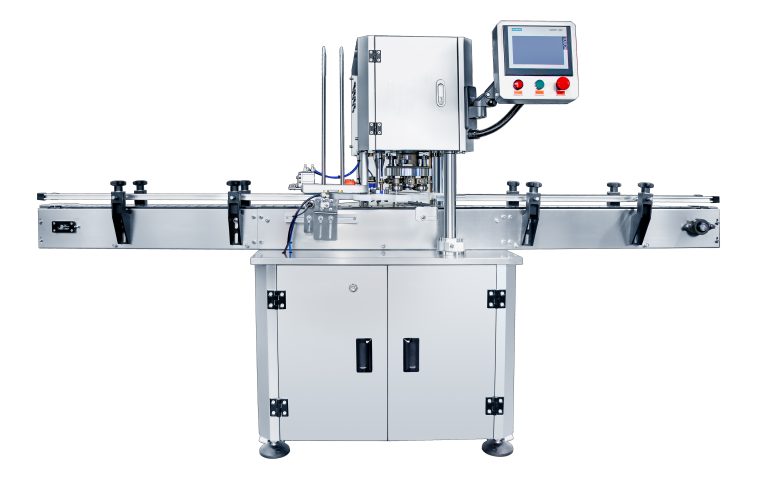

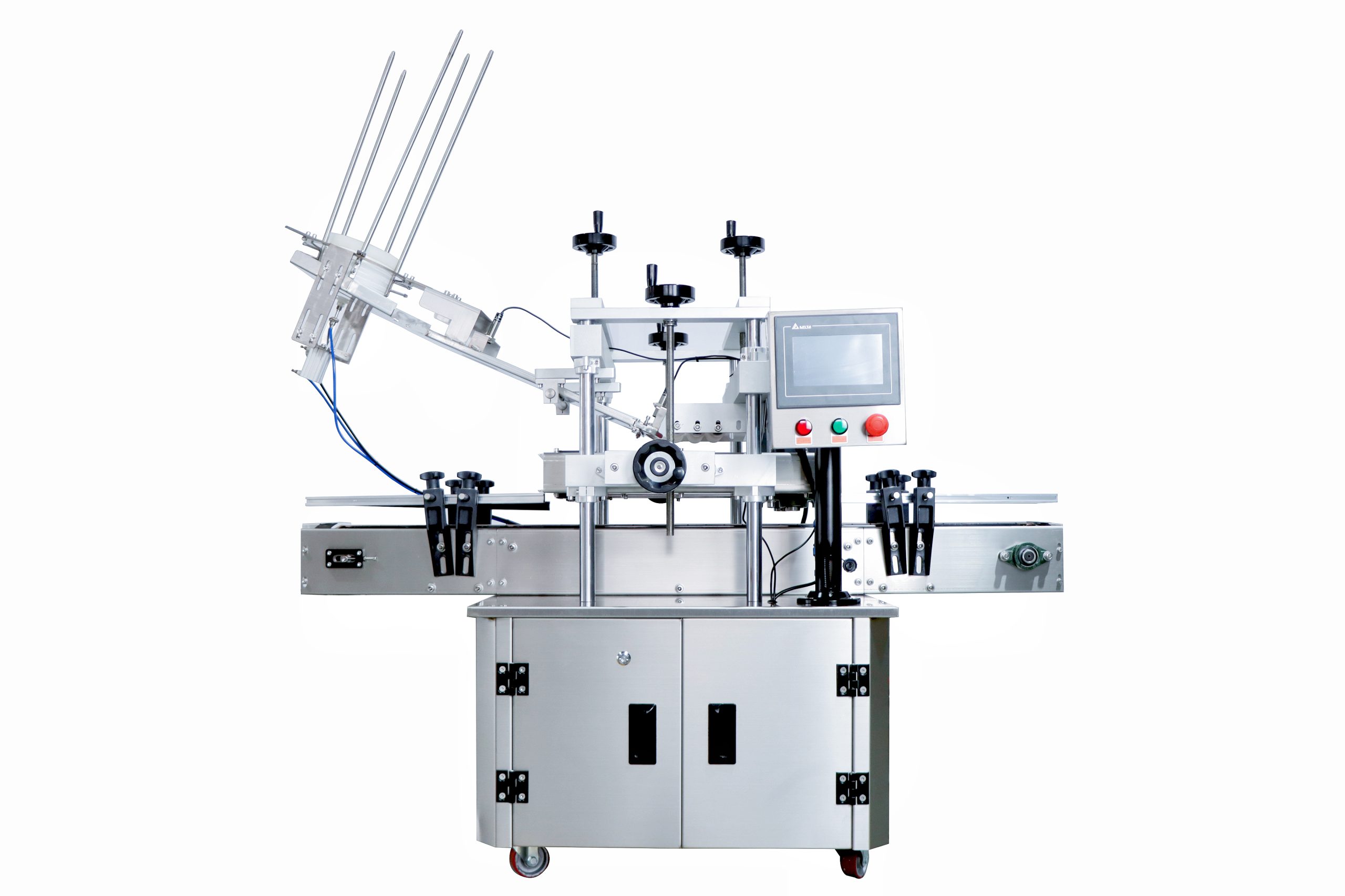

An automatic sheep milk cheese tin can press capping machine is a valuable piece of equipment for dairy producers looking to streamline their production process. This machine offers a range of benefits that can help improve efficiency, reduce labor costs, and ensure consistent quality in the final product.

One of the key benefits of using an automatic sheep milk cheese tin can press capping machine is its ability to increase production speed. By automating the process of capping cheese tins, this machine can significantly reduce the time it takes to package each product. This can be especially beneficial for dairy producers who are looking to scale up their operations and increase their output.

In addition to speeding up production, an automatic sheep milk cheese tin can press capping machine can also help reduce labor costs. By automating the capping process, dairy producers can free up their employees to focus on other tasks, such as quality control or product development. This can help improve overall efficiency and productivity within the dairy production facility.

Another benefit of using an automatic sheep milk cheese tin can press capping machine is its ability to ensure consistent quality in the final product. By automating the capping process, this machine can help reduce the risk of human error and ensure that each tin is sealed properly. This can help improve the shelf life of the product and reduce the risk of contamination or spoilage.

Furthermore, an automatic sheep milk cheese tin can press capping machine can help improve overall safety in the dairy production facility. By automating the capping process, this machine can help reduce the risk of injuries or accidents that can occur when employees are manually capping tins. This can help create a safer work environment for employees and reduce the risk of costly workplace accidents.

Overall, an automatic sheep milk cheese tin can press capping machine offers a range of benefits for dairy producers looking to improve efficiency, reduce labor costs, and ensure consistent quality in their products. By automating the capping process, this machine can help increase production speed, reduce labor costs, ensure consistent quality, and improve overall safety in the dairy production facility. For dairy producers looking to streamline their production process and improve the quality of their products, investing in an automatic sheep milk cheese tin can press capping machine can be a wise decision.

How to Choose the Right Automatic Sheep Milk Cheese Tin Can Press Capping Machine for Your Business

When it comes to producing and packaging sheep milk cheese, having the right equipment is essential to ensure efficiency and quality. One important piece of machinery that can streamline the packaging process is an automatic sheep milk cheese tin can press capping machine. This machine is designed to automatically press and cap tin cans filled with sheep milk cheese, making the packaging process faster and more efficient. However, with so many options available on the market, choosing the right automatic sheep milk cheese tin can press capping machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting the right machine for your needs.

First and foremost, it is important to consider the production capacity of the automatic sheep milk cheese tin can press capping machine. Different machines have different capacities, so it is crucial to choose one that can meet the demands of your business. Consider factors such as the size of your production line, the volume of sheep milk cheese you produce, and your future growth projections. Selecting a machine with a capacity that aligns with your production needs will help ensure that your packaging process runs smoothly and efficiently.

Another important factor to consider when choosing an automatic sheep milk cheese tin can press capping machine is the level of automation it offers. Some machines are fully automated, meaning they can perform all the necessary tasks without human intervention. Others may require some manual input, such as loading cans onto the machine or adjusting settings. Consider your business’s specific needs and capabilities when deciding on the level of automation that is right for you. While fully automated machines may offer increased efficiency, they may also come with a higher price tag.

In addition to capacity and automation, it is important to consider the quality and reliability of the automatic sheep milk cheese tin can press capping machine. Look for machines made from high-quality materials that are built to last. Consider the reputation of the manufacturer and read reviews from other customers to gauge the machine’s reliability. Investing in a high-quality machine may require a larger upfront cost, but it can save you money in the long run by reducing maintenance and repair costs.

When selecting an automatic sheep milk cheese tin can press capping machine, it is also important to consider the machine’s compatibility with your existing production line. Ensure that the machine can easily integrate with your current equipment and processes to avoid any disruptions or inefficiencies. Consider factors such as the machine’s size, power requirements, and compatibility with your packaging materials.

In conclusion, choosing the right automatic sheep milk cheese tin can press capping machine for your business is a crucial decision that can impact the efficiency and quality of your packaging process. Consider factors such as production capacity, level of automation, quality and reliability, and compatibility with your existing production line when making your decision. By carefully evaluating these factors and selecting a machine that meets your specific needs, you can streamline your packaging process and improve the overall efficiency of your business.