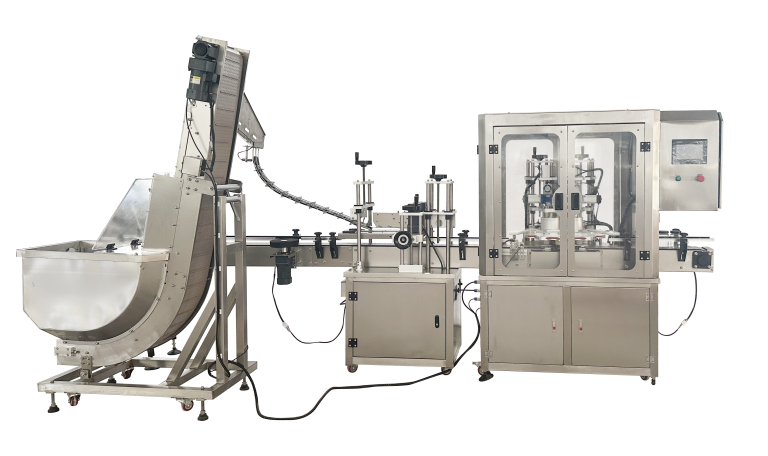

In the fast-paced world of packaging, the automatic high speed cap top labeling machine stands out as a true game-changer.

This machine is engineered to handle the task of applying labels to the tops of caps at an incredibly high speed. It is capable of quickly and accurately placing labels on a large number of caps per minute, significantly increasing the packaging production rate.

One of its key features is its precision. Despite the high speed of operation, it maintains a high level of accuracy in label placement. Each label is precisely positioned on the cap top, ensuring a neat and professional appearance, which is essential for product presentation.

The machine is highly adaptable and can handle a wide variety of cap sizes and shapes. It easily adjusts to different labeling requirements, making it suitable for use with a diverse range of products in various industries.

With its automatic operation, it eliminates the need for manual labor in the labeling process. This not only saves labor costs but also reduces the potential for human errors, ensuring consistent and reliable labeling every time.

Furthermore, the automatic high speed cap top labeling machine is often equipped with advanced control systems and sensors. These help monitor the labeling process in real-time, detecting any issues such as mislabeling or label damage and allowing for immediate corrective action.

In conclusion, this automatic high speed cap top labeling machine is an essential asset for any packaging operation that demands high speed, precision, and efficiency. It helps streamline the packaging process, improves productivity, and ultimately delivers better-quality packaged products to the market.

Stay tuned to our blogs for more updates on the latest advancements in packaging machinery.

-768x622.jpg)