It seems we can’t find what you’re looking for. Perhaps searching can help.

“How Automatic Servo Can Seamers Revolutionize Can Sealing Processes”

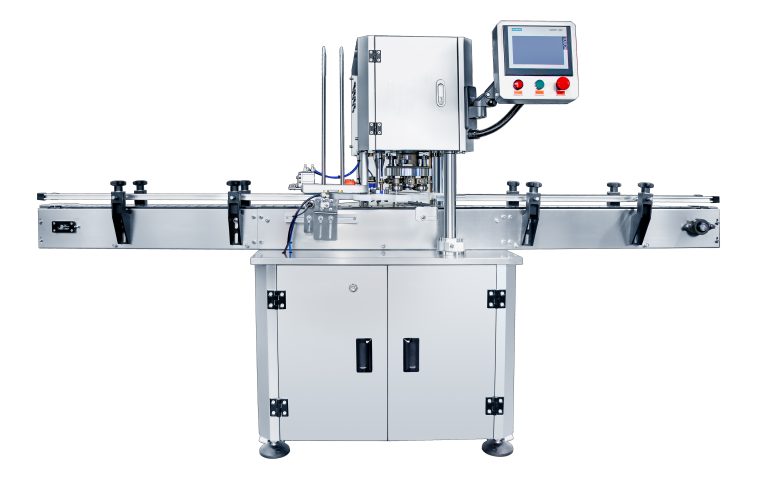

Automatic servo can seamers have brought about a remarkable transformation in the world of can sealing. These advanced machines offer unprecedented levels of precision and accuracy. The servo technology ensures that each can is sealed with exact force and alignment, eliminating variations and reducing the risk of leaks or faulty…