It seems we can’t find what you’re looking for. Perhaps searching can help.

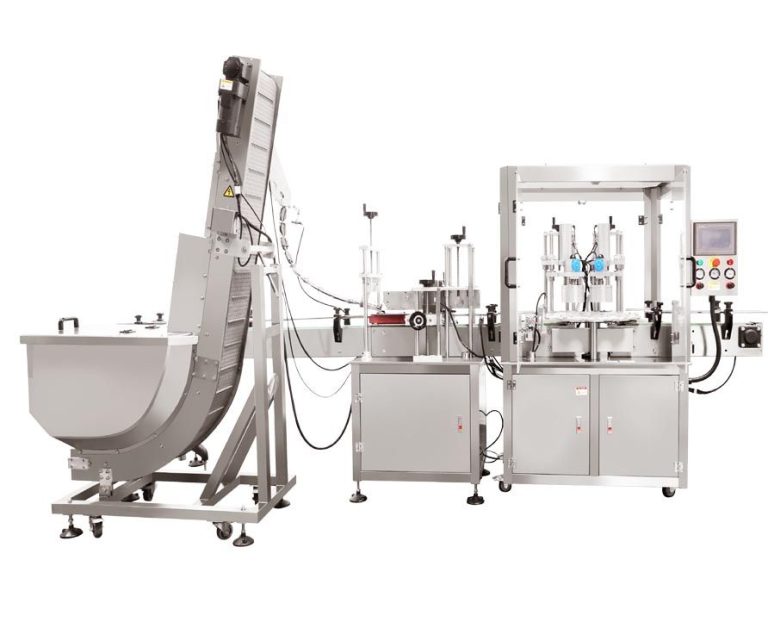

Fully automatic milk powder vacuum filling nitrogen sealing machine

Benefits of Using Fully Automatic Milk Powder Vacuum Filling Nitrogen Sealing Machine In the food industry, packaging plays a crucial role in maintaining the quality and freshness of products. When it comes to milk powder, proper packaging is essential to prevent spoilage and ensure a longer shelf life. One of…