Table of Contents

Benefits of Using a Canned Food Seaming Machine for Tin Cans

Canned food has been a staple in households for decades, providing convenience and long shelf life for a variety of food items. One crucial component of canned food production is the seaming process, which ensures that the can is properly sealed to maintain freshness and prevent contamination. In recent years, advancements in technology have led to the development of canned food seaming machines specifically designed for tin cans, offering numerous benefits for manufacturers and consumers alike.

One of the primary advantages of using a canned food seaming machine for tin cans is the consistency and precision it provides in the seaming process. Manual seaming can be prone to human error, resulting in improperly sealed cans that may compromise the quality and safety of the food inside. With a seaming machine, each can is sealed with the same level of accuracy, ensuring a tight and secure seal every time. This not only improves the overall quality of the product but also reduces the risk of spoilage and contamination.

In addition to consistency, canned food seaming machines are also capable of high-speed production, allowing manufacturers to increase their output and meet the demands of a growing market. These machines can seam hundreds of cans per minute, significantly reducing production time and labor costs. This increased efficiency not only benefits manufacturers by improving their bottom line but also ensures a steady supply of canned food products for consumers.

Furthermore, canned food seaming machines are designed to be versatile and adaptable to different can sizes and shapes. This flexibility allows manufacturers to produce a wide range of canned food products without the need for multiple machines or extensive retooling. Whether it’s small tin cans for individual servings or larger cans for family-sized portions, a seaming machine can easily adjust to accommodate various packaging requirements.

Another key benefit of using a canned food seaming machine is the improved safety and hygiene it provides during the production process. Seaming machines are equipped with advanced features such as automatic lid feeders and seam inspection systems, which help to minimize the risk of contamination and ensure that each can is properly sealed. This not only meets regulatory standards for food safety but also gives consumers peace of mind knowing that the products they purchase are of the highest quality.

In conclusion, the use of a canned food seaming machine for tin cans offers numerous benefits for both manufacturers and consumers. From improved consistency and efficiency to enhanced safety and hygiene, these machines play a crucial role in the production of high-quality canned food products. As the demand for canned food continues to grow, investing in a seaming machine can help manufacturers stay competitive in the market and meet the needs of consumers for convenient and reliable food options.

How to Choose the Right Canned Food Seaming Machine for Your Production Line

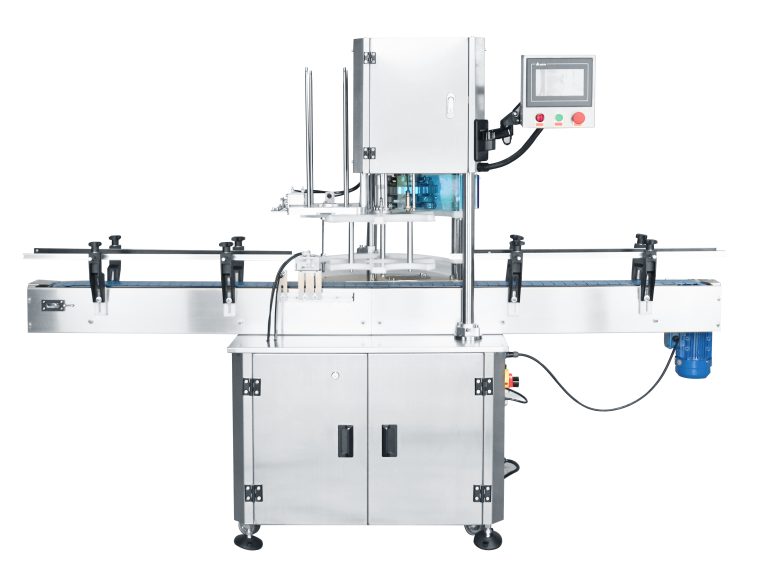

Canned food seaming machines are essential equipment for any food production line that packages products in tin cans. These machines are responsible for sealing the cans to ensure the contents remain fresh and safe for consumption. Choosing the right seaming machine for your production line is crucial to ensure efficiency, quality, and consistency in your canned food products.

When selecting a canned food seaming machine, there are several factors to consider. The first consideration is the type of cans you will be using. Different seaming machines are designed to work with specific can sizes and shapes. It is important to choose a machine that is compatible with the cans you will be using to avoid any issues with the sealing process.

Another important factor to consider is the production capacity of the seaming machine. The machine should be able to keep up with the demands of your production line to avoid any bottlenecks or delays. Consider the speed at which the machine can seam cans and ensure it aligns with your production goals.

Additionally, it is important to consider the level of automation of the seaming machine. Fully automated machines can increase efficiency and reduce the risk of human error. However, they may also require more maintenance and technical expertise to operate. Semi-automated machines offer a balance between efficiency and ease of use.

The quality of the seaming machine is also a crucial factor to consider. Look for machines made from high-quality materials that are durable and reliable. A well-built machine will last longer and require less maintenance, saving you time and money in the long run.

Consider the reputation of the manufacturer when choosing a seaming machine. Look for companies with a track record of producing high-quality equipment and providing excellent customer service. A reputable manufacturer will be able to provide support and assistance if any issues arise with the machine.

When selecting a canned food seaming machine, it is also important to consider your budget. Seaming machines can vary widely in price, so it is important to choose a machine that fits within your budget while still meeting your production needs. Consider the long-term costs of maintenance and operation when making your decision.

In conclusion, choosing the right canned food seaming machine for your production line is essential to ensure the quality and efficiency of your canned food products. Consider factors such as can compatibility, production capacity, automation level, quality, manufacturer reputation, and budget when making your decision. By carefully evaluating these factors, you can select a seaming machine that meets your needs and helps your production line run smoothly and efficiently.