Table of Contents

Benefits of Using an Automatic Bottle Labeling Machine with Adhesive Sticker Applicator

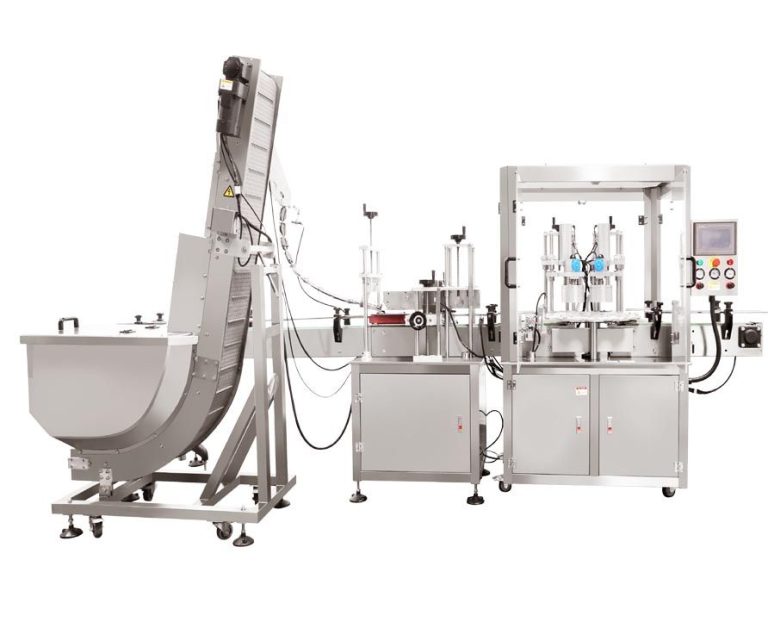

An automatic bottle labeling machine with adhesive sticker applicator is a valuable tool for businesses looking to streamline their labeling process. This machine offers a range of benefits that can help improve efficiency, accuracy, and overall productivity. In this article, we will explore some of the key advantages of using an automatic bottle labeling machine with adhesive sticker applicator.

One of the primary benefits of using an automatic bottle labeling machine is the speed at which it can apply labels to bottles. These machines are designed to work quickly and efficiently, allowing businesses to label large quantities of bottles in a short amount of time. This can help to reduce production times and increase output, ultimately leading to cost savings and improved profitability.

In addition to speed, automatic bottle labeling machines also offer a high level of accuracy. These machines are programmed to apply labels precisely and consistently, ensuring that each bottle is labeled correctly every time. This can help to eliminate errors and reduce the risk of mislabeling, which can be costly and time-consuming to correct.

Another benefit of using an automatic bottle labeling machine is the versatility it offers. These machines can be easily adjusted to accommodate different bottle sizes and shapes, as well as a variety of label types. This flexibility allows businesses to label a wide range of products with ease, making the machine a valuable investment for companies with diverse labeling needs.

Furthermore, automatic bottle labeling machines with adhesive sticker applicators are easy to operate and require minimal training. This means that businesses can quickly integrate the machine into their production process without the need for extensive training or specialized skills. This can help to reduce downtime and ensure that the machine is up and running quickly, maximizing its efficiency and productivity.

In addition to these benefits, automatic bottle labeling machines with adhesive sticker applicators are also cost-effective. These machines are designed to be durable and long-lasting, requiring minimal maintenance and upkeep. This can help to reduce operating costs and extend the lifespan of the machine, making it a cost-effective solution for businesses looking to improve their labeling process.

Overall, an automatic bottle labeling machine with adhesive sticker applicator offers a range of benefits that can help businesses improve efficiency, accuracy, and productivity. From speed and accuracy to versatility and cost-effectiveness, these machines are a valuable tool for companies looking to streamline their labeling process and increase profitability. By investing in an automatic bottle labeling machine, businesses can enjoy the many advantages that this technology has to offer.

How to Choose the Right Automatic Bottle Labeling Machine for Your Business

When it comes to packaging and branding products, having the right labeling machine can make a significant difference in the efficiency and quality of your production process. Automatic bottle labeling machines with adhesive sticker applicators are a popular choice for businesses looking to streamline their labeling process and ensure consistent results. However, with so many options available on the market, choosing the right machine for your business can be a daunting task. In this article, we will discuss some key factors to consider when selecting an automatic bottle labeling machine with adhesive sticker applicator to help you make an informed decision.

One of the first things to consider when choosing an automatic bottle labeling machine is the speed and capacity of the machine. Depending on the size of your production line and the volume of bottles you need to label, you will need to select a machine that can keep up with your production demands. Look for machines that offer adjustable speed settings and can handle a wide range of bottle sizes to ensure maximum flexibility and efficiency.

Another important factor to consider is the accuracy and precision of the labeling machine. The last thing you want is for your labels to be crooked or misaligned, as this can negatively impact the overall appearance of your products. Look for machines that offer precise label placement and alignment features to ensure consistent and professional-looking results every time.

In addition to speed and accuracy, it is also important to consider the ease of use and maintenance of the labeling machine. Look for machines that are user-friendly and intuitive to operate, with clear instructions and minimal setup required. Additionally, consider the maintenance requirements of the machine, such as the frequency of cleaning and the availability of replacement parts. Choosing a machine that is easy to maintain will help minimize downtime and ensure smooth operation of your production line.

When selecting an automatic bottle labeling machine with adhesive sticker applicator, it is also important to consider the compatibility of the machine with your existing production equipment. Make sure that the machine is compatible with the types of bottles and labels you use in your production process, and that it can be easily integrated into your existing workflow. Additionally, consider the space requirements of the machine and ensure that it will fit comfortably within your production facility.

Finally, consider the reputation and reliability of the manufacturer when choosing an automatic bottle labeling machine. Look for manufacturers with a proven track record of producing high-quality machines that are built to last. Read reviews and testimonials from other customers to get a sense of the machine’s performance and reliability in real-world production environments.

In conclusion, choosing the right automatic bottle labeling machine with adhesive sticker applicator is a crucial decision that can have a significant impact on the efficiency and quality of your production process. By considering factors such as speed, accuracy, ease of use, compatibility, and reliability, you can select a machine that meets your specific needs and helps you achieve your production goals. Take the time to research and compare different machines to find the best fit for your business, and invest in a high-quality machine that will help you streamline your labeling process and enhance the overall quality of your products.