It seems we can’t find what you’re looking for. Perhaps searching can help.

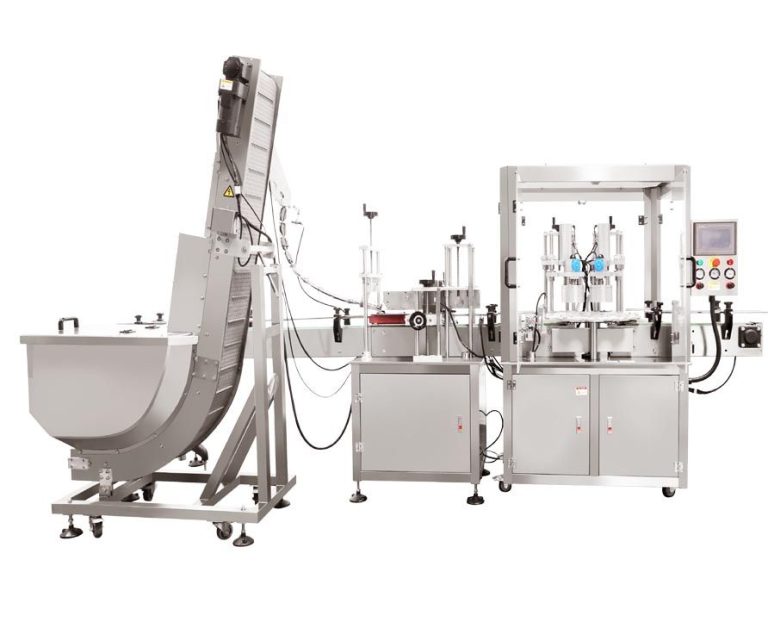

Smart Manufacturing: Automatic Glass Bottle Vacuum Capping Machines Leading the Way

In the era of Industry 4.0, smart manufacturing has emerged as a revolutionary concept that is transforming the industrial landscape. Automatic glass bottle vacuum capping machines are at the forefront of this transformation, integrating advanced technologies to enhance efficiency, quality, and flexibility in the packaging process. The Foundation of Smart…