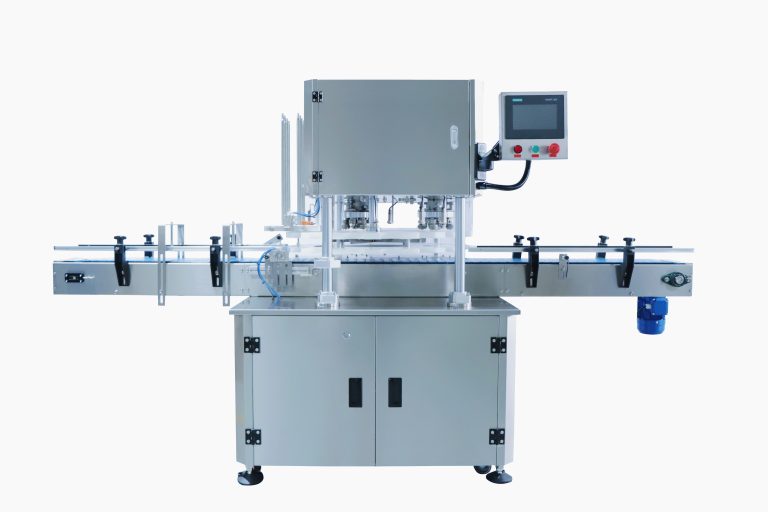

In the fast-paced world of manufacturing and packaging, every second counts. The Automatic Dual Head Servo Bottle Capping Machine has emerged as a game-changer, significantly boosting productivity in various industries.

One of the key ways this machine enhances productivity is through its dual-head design. By operating two heads simultaneously, it doubles the capping speed compared to single-head machines. This means more bottles can be capped in a shorter period, allowing for higher production output.

The precision and accuracy of the servo technology incorporated in this machine also contribute to productivity gains. It ensures that each cap is applied perfectly, minimizing errors and rework. This not only saves time but also reduces the waste of materials and resources.

Furthermore, the Automatic Dual Head Servo Bottle Capping Machine is highly automated, reducing the need for manual intervention. This eliminates human errors and allows workers to focus on other important tasks, optimizing the overall workflow and productivity of the production line.

Its ability to handle a wide range of bottle sizes and cap types adds to its productivity-boosting capabilities. It provides flexibility and eliminates the need for frequent machine adjustments when switching between different products.

In conclusion, the Automatic Dual Head Servo Bottle Capping Machine is a powerful tool that revolutionizes productivity in the packaging sector. Its advanced features and efficient operation make it an indispensable asset for businesses aiming to stay ahead in the competitive market.