In the dynamic world of food production, the packaging process is as crucial as the product itself. When it comes to sauce packaging, an automatic sauce piston filling machine emerges as the linchpin that combines precision and speed, revolutionizing the way sauces are prepared for the market.

Table of Contents

Precision in Every Drop

The cornerstone of an automatic sauce piston filling machine is its ability to deliver unparalleled precision. The piston mechanism is engineered to draw in a specific volume of sauce and dispense it into containers with exactitude. This is especially vital for sauces, as consistency in quantity is not just a matter of customer satisfaction but also regulatory compliance.

Imagine a high – end gourmet sauce brand. Each bottle must contain the same amount of sauce to maintain the brand’s reputation for quality. The automatic sauce piston filling machine ensures that whether it’s a small batch for a local market or a large – scale production for national distribution, every container is filled to the precise specification. This precision also minimizes waste, as there is no over – filling or under – filling, which can lead to product loss and increased costs.

High – Speed Production Capabilities

In today’s fast – paced consumer market, speed is of the essence. Automatic sauce piston filling machines are designed to operate at remarkable speeds, enabling manufacturers to meet high – volume demands efficiently.

These machines can fill a large number of containers in a short period. For example, in a busy sauce factory, an automatic piston filling machine can fill hundreds of bottles per minute. This high – speed production allows companies to keep up with the ever – increasing market demand, whether it’s for popular condiments like ketchup or niche artisanal sauces. The ability to produce at a rapid pace also gives businesses a competitive edge, as they can respond quickly to market trends and seasonal demands.

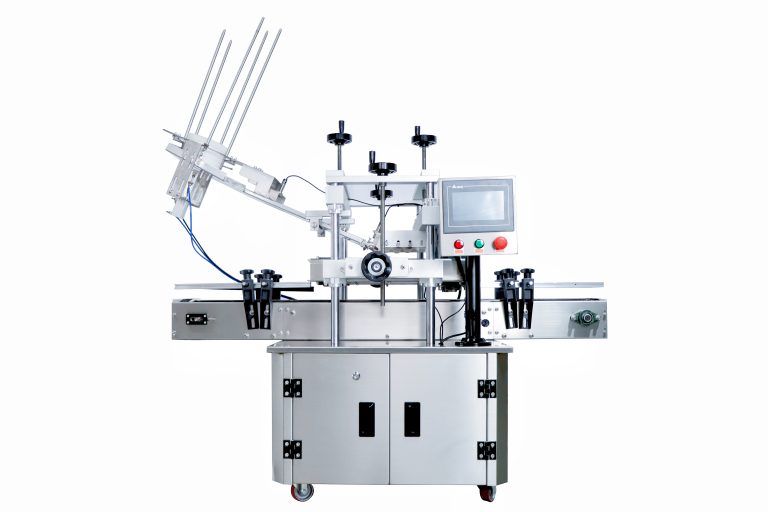

Adaptability to Different Sauce Viscosities

Sauces come in a wide range of viscosities, from thin and runny to thick and chunky. An automatic sauce piston filling machine is highly adaptable and can handle all types of sauces with ease.

For thin sauces such as soy sauce or vinegar, the machine can adjust its filling speed and pressure to ensure a smooth and consistent flow. On the other hand, for thick and chunky sauces like salsa or barbecue sauce with large pieces of vegetables or meat, the piston mechanism can effectively handle the solids without clogging. This adaptability makes the machine suitable for a diverse range of sauce products, eliminating the need for multiple filling systems.

Hygienic Design

Hygiene is a top priority in the food industry, and automatic sauce piston filling machines are designed with this in mind. They are constructed using food – grade materials that are resistant to corrosion and easy to clean.

The smooth surfaces of the machine prevent the accumulation of sauce residues, which can harbor bacteria. Additionally, many machines are designed with removable parts that can be easily disassembled for thorough cleaning and sanitization. This ensures that the sauce remains safe for consumption and that the machine meets strict food safety standards.

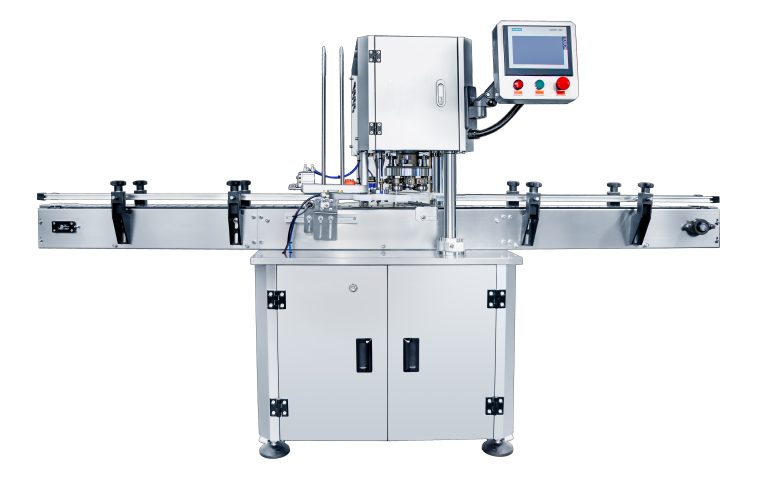

User – Friendly Operation

Operating an automatic sauce piston filling machine is relatively simple, even for those with limited technical expertise. Most machines are equipped with intuitive control panels that allow operators to set parameters such as filling volume, speed, and the number of containers to be filled.

This user – friendly design reduces the need for extensive training and enables operators to quickly adjust the machine according to different production requirements. It also minimizes the chances of human error, ensuring consistent and reliable performance.

Integration with Packaging Lines

Automatic sauce piston filling machines can be seamlessly integrated into existing packaging lines. They can work in conjunction with other equipment such as cappers, labelers, and conveyors.

Once the sauce is filled into the containers, the cappers can immediately seal the bottles, and the labelers can apply the product labels. The conveyor system then transports the filled and labeled containers to the next stage of the packaging process. This integration creates a continuous and efficient production flow, reducing labor costs and increasing overall productivity.

In conclusion, the automatic sauce piston filling machine is the key to achieving precise and fast sauce packaging. Its precision, speed, adaptability, hygienic design, user – friendly operation, and integration capabilities make it an essential investment for sauce manufacturers looking to enhance their production processes and meet the demands of the modern market.