Double-Head Servo Screw Capping Machines are advanced pieces of equipment that have revolutionized the capping process in various industries. This guide will take you through everything you need to know about them.

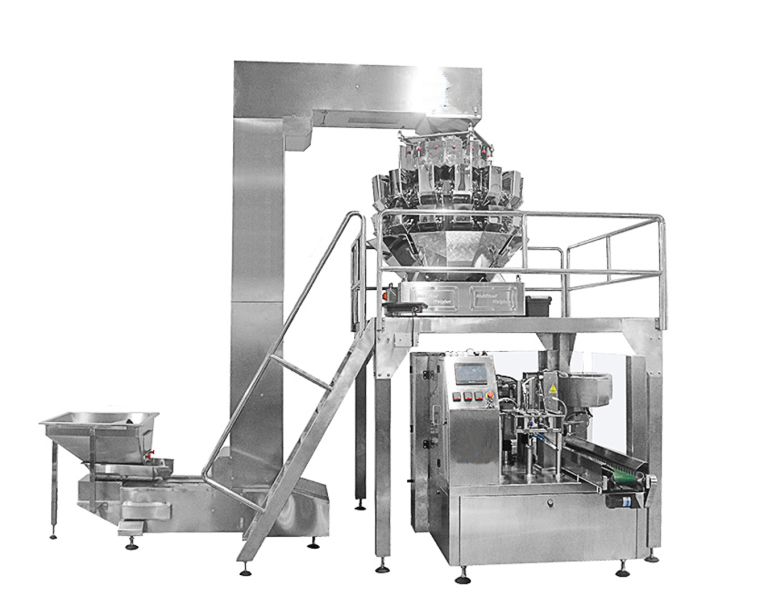

Let’s start with the basic structure. These machines typically consist of a conveyor system to transport containers, cap feeding mechanisms, and of course, the double capping heads powered by servo technology.

The servo system is a key component. It provides precise control over the speed, torque, and position of the capping heads, ensuring accurate and consistent capping every time. This level of control is crucial for achieving a tight and secure seal on the containers.

The cap feeding mechanism is designed to supply caps smoothly and accurately to the capping heads. It often incorporates sensors and sorting systems to ensure that only properly oriented caps are presented for capping.

-1024x683.jpg)

When it comes to operation, these machines are highly automated. Once the containers and caps are loaded onto the machine, the process begins automatically. The conveyor moves the containers into position, the capping heads descend, and the caps are screwed on with the desired force and tightness.

Double-Head Servo Screw Capping Machines offer several advantages. Their dual-head design significantly increases productivity compared to single-head machines. The precision of the servo system ensures high-quality capping, reducing the risk of leaks or loose caps. They are also highly adaptable and can handle a wide range of container and cap sizes and shapes.

Maintenance is an important aspect to consider. Regular checks of the mechanical components, lubrication, and calibration of the servo system are necessary to ensure optimal performance and longevity of the machine.

In conclusion, Double-Head Servo Screw Capping Machines are essential for businesses looking to enhance their capping operations, improve product quality, and increase efficiency. With the right understanding and maintenance, they can be a valuable asset in any production line.