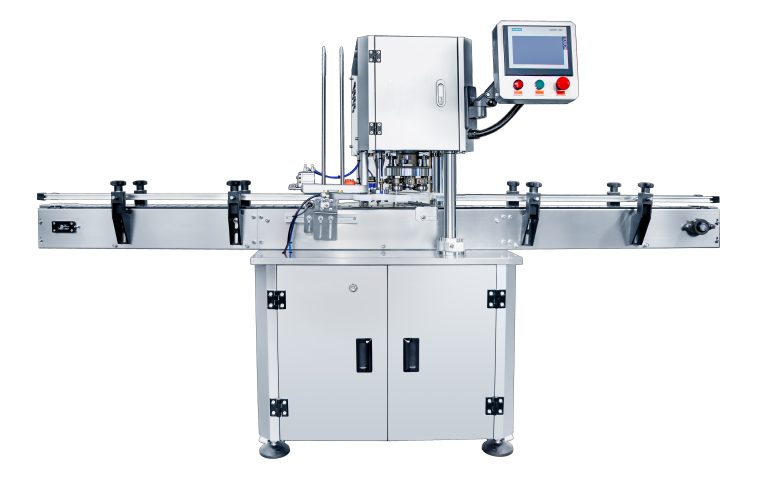

In the world of packaging, the 4-wheels capping machine for pump cap has emerged as a game-changer. This innovative piece of equipment is transforming the way products with pump caps are capped and sealed.

One of the key advantages of this 4-wheels capping machine is its speed and accuracy. It can handle a large volume of containers in a short period, ensuring that each pump cap is applied precisely and securely. This not only boosts productivity but also reduces the chances of errors or loose caps.

The design of the 4-wheels configuration provides stability and smooth operation. It allows for seamless movement during the capping process, minimizing any potential jams or disruptions. This results in a continuous workflow and higher output.

This machine is highly adaptable and can accommodate different sizes and styles of pump caps. Whether it’s for cosmetics, cleaning products, or healthcare items, its flexibility makes it suitable for a wide range of industries.

The quality of the capping is consistently excellent. The machine applies the right amount of torque, ensuring a proper seal that protects the contents and enhances the product’s integrity.

Another notable feature is its ease of use and maintenance. Operators can quickly learn how to operate the machine, and routine servicing is straightforward, minimizing downtime and maximizing operational efficiency.

The 4-wheels capping machine for pump cap is a testament to technological advancement in the packaging sector. It offers a reliable and efficient solution for businesses looking to streamline their packaging processes and deliver top-quality products to the market.

Stay tuned for more updates on the latest packaging machinery innovations!