In the fields of pharma, food, and chemicals, the handling and packaging of fine powders require precise and reliable methods. Auger filling technology emerges as the ideal choice for several compelling reasons.

Firstly, auger fillers offer exceptional accuracy when dealing with fine powders. The controlled rotation of the auger screw ensures that the exact amount of powder is dispensed every time, meeting strict quality and regulatory standards in the pharma industry and guaranteeing consistent portion sizes in food products.

The gentle nature of the auger filling process is crucial for fine powders. It minimizes the disruption and potential damage to the powder particles, preserving their integrity and properties. This is especially important in the pharmaceutical sector where the efficacy of drugs can be affected by particle alteration.

In the food industry, hygiene is paramount. Auger filling technology is designed to prevent cross-contamination and maintain a clean filling environment, ensuring the safety and quality of food products.

For the chemical industry, the ability of auger fillers to handle a wide range of powder characteristics and compositions makes them highly adaptable. They can accurately fill containers with different chemicals, regardless of their particle size or flow properties.

Auger filling technology also provides a consistent and repeatable filling process. This is essential for maintaining product quality and reducing variations, which is critical in all three sectors – pharma, food, and chemicals.

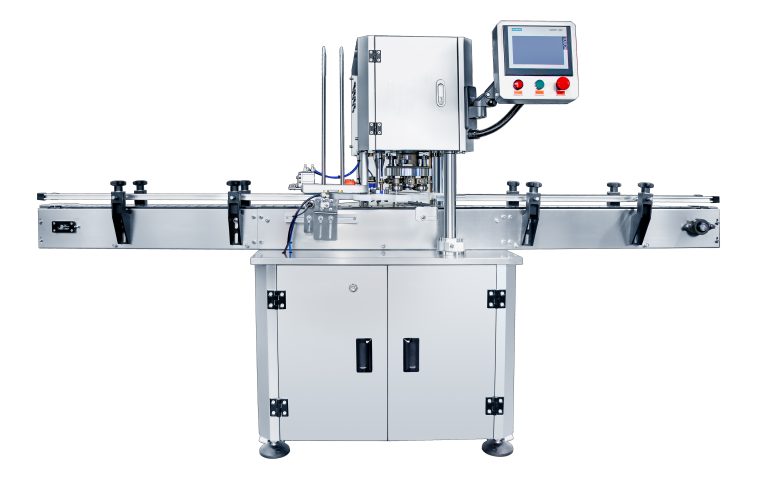

Furthermore, these fillers can be integrated into automated production lines, enhancing overall efficiency and productivity.

In conclusion, the combination of accuracy, gentle handling, hygiene, adaptability, and consistency makes auger filling technology the perfect solution for the precise and reliable packaging of fine powders in the pharma, food, and chemical industries.