Table of Contents

Benefits of Using Automatic Powder Filling Machines

Powder filling machines are essential equipment in various industries that deal with powdered products. These machines are designed to accurately fill containers with a predetermined amount of powder, ensuring consistency and efficiency in the production process. There are different types of powder filling machines available, each with its own unique features and applications. In this article, we will explore the benefits of using automatic powder filling machines in various industries.

One of the main advantages of using automatic powder filling machines is their ability to increase productivity and efficiency. These machines are capable of filling containers at a much faster rate than manual filling methods, saving time and labor costs. Automatic powder filling machines are also highly accurate, ensuring that each container is filled with the exact amount of powder required. This helps to reduce waste and improve overall product quality.

Another benefit of using automatic powder filling machines is their versatility. These machines can be used to fill a wide range of containers, including bottles, jars, pouches, and bags. They can also handle a variety of powdered products, such as spices, pharmaceuticals, chemicals, and food products. This flexibility makes automatic powder filling machines ideal for use in diverse industries, from food and beverage to pharmaceuticals and cosmetics.

In addition to increasing productivity and versatility, automatic powder filling machines also offer improved safety and hygiene benefits. These machines are designed to minimize the risk of contamination and ensure that the powder is handled in a clean and sanitary manner. This is particularly important in industries such as pharmaceuticals and food production, where product safety and quality are paramount. Automatic powder filling machines help to reduce the risk of product contamination and ensure that the final product meets strict quality standards.

Furthermore, automatic powder filling machines are easy to operate and maintain. Most modern machines are equipped with user-friendly interfaces and controls, making them simple to set up and operate. These machines also require minimal maintenance, reducing downtime and ensuring continuous production. This ease of use and maintenance makes automatic powder filling machines a cost-effective solution for businesses looking to streamline their production processes.

Overall, automatic powder filling machines offer a range of benefits for businesses in various industries. From increased productivity and efficiency to improved safety and hygiene, these machines are a valuable asset for any production facility. Whether you are filling containers with spices, pharmaceuticals, or food products, automatic powder filling machines can help you achieve consistent and high-quality results. Consider investing in an automatic powder filling machine for your business to take advantage of these benefits and improve your production processes.

Different Types of Powder Filling Machines Available in the Market

Powder filling machines are essential equipment in various industries that deal with powdered products. These machines are designed to accurately fill containers with a specific amount of powder, ensuring consistency and efficiency in the production process. There are several types of powder filling machines available in the market, each with its own unique features and applications.

One of the most common types of powder filling machines is the auger filling machine. This type of machine uses a rotating auger to dispense a precise amount of powder into containers. Auger filling machines are ideal for filling fine powders, such as flour, sugar, and spices, as they can accurately measure and dispense small amounts of powder with high precision.

Another popular type of powder filling machine is the piston filling machine. This machine uses a piston mechanism to push powder into containers, making it suitable for filling thick or viscous powders, such as pharmaceuticals, cosmetics, and chemicals. Piston filling machines are known for their high filling accuracy and can handle a wide range of powder viscosities.

Gravity filling machines are also commonly used in industries that require fast and efficient powder filling. These machines rely on gravity to fill containers with powder, making them ideal for filling lightweight powders, such as talc, powdered milk, and detergent. Gravity filling machines are easy to operate and maintain, making them a popular choice for small to medium-sized businesses.

In addition to these types of powder filling machines, there are also specialized machines designed for specific applications. For example, vacuum filling machines are used in industries that require airtight packaging for sensitive powders, such as pharmaceuticals and food products. These machines remove air from the containers before filling them with powder, ensuring product freshness and longevity.

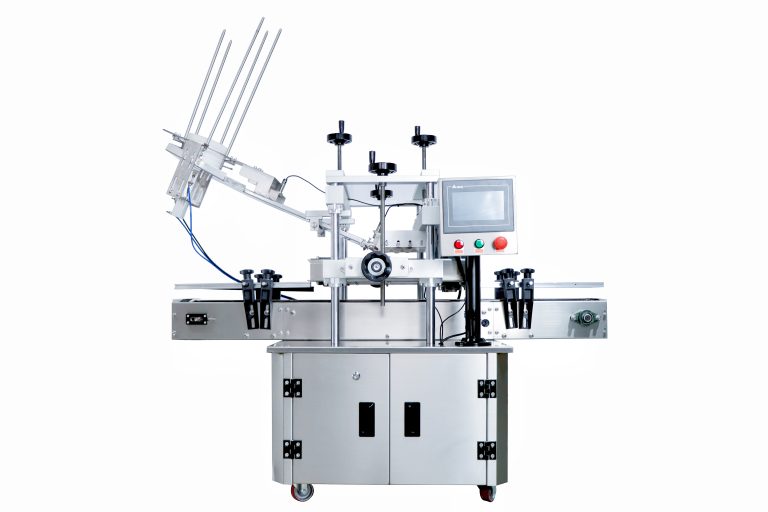

Powder filling machines can also be classified based on their automation level. Semi-automatic machines require manual intervention to load containers and start the filling process, while fully automatic machines can operate independently once they are set up. Fully automatic powder filling machines are ideal for high-volume production lines that require consistent and efficient filling operations.

When choosing a powder filling machine for your business, it is important to consider factors such as the type of powder being filled, the desired filling accuracy, production volume, and budget. It is also essential to ensure that the machine is compatible with your existing production line and meets industry standards for quality and safety.

In conclusion, powder filling machines play a crucial role in the manufacturing process of powdered products. With a wide range of types and applications available in the market, businesses can choose the right machine to meet their specific needs and requirements. Whether you are filling fine powders, thick pastes, or lightweight powders, there is a powder filling machine that can help streamline your production process and improve overall efficiency.

Applications of Powder Filling Machines in Various Industries

Powder filling machines are essential equipment in various industries for efficiently filling containers with powdered substances. These machines come in different types and are designed to meet the specific needs of different industries. In this article, we will explore the applications of powder filling machines in various industries and the types of machines commonly used.

In the pharmaceutical industry, powder filling machines play a crucial role in accurately filling capsules and tablets with powdered medications. These machines are designed to handle a wide range of powders, from fine powders to granules, ensuring precise dosing and minimizing wastage. The high-speed capabilities of these machines make them ideal for large-scale production, where efficiency and accuracy are paramount.

In the food and beverage industry, powder filling machines are used to fill containers with various powdered ingredients such as spices, flour, sugar, and protein powders. These machines are designed to handle different types of powders, from free-flowing to non-free-flowing, ensuring consistent filling and packaging. The versatility of these machines allows food manufacturers to meet the diverse packaging requirements of their products.

In the cosmetic industry, powder filling machines are used to fill containers with powdered makeup products such as eyeshadows, blushes, and powders. These machines are designed to handle delicate powders with care, ensuring that the integrity of the product is maintained during the filling process. The precision dosing capabilities of these machines allow cosmetic manufacturers to achieve uniform filling and packaging, enhancing the overall quality of their products.

In the chemical industry, powder filling machines are used to fill containers with various powdered chemicals such as fertilizers, detergents, and pigments. These machines are designed to handle corrosive and hazardous powders safely, ensuring the safety of operators and the integrity of the product. The robust construction of these machines makes them suitable for handling a wide range of powders, from fine powders to abrasive powders.

In the agricultural industry, powder filling machines are used to fill containers with powdered pesticides, herbicides, and fertilizers. These machines are designed to handle dusty and granular powders efficiently, ensuring accurate dosing and minimizing spillage. The high-speed capabilities of these machines make them ideal for large-scale production, where speed and accuracy are essential.

In conclusion, powder filling machines are versatile equipment that finds applications in various industries for efficiently filling containers with powdered substances. These machines are designed to handle different types of powders and meet the specific needs of different industries. Whether it is the pharmaceutical, food and beverage, cosmetic, chemical, or agricultural industry, powder filling machines play a crucial role in ensuring accurate dosing, consistent filling, and efficient packaging. The advancements in technology have led to the development of innovative powder filling machines that offer enhanced capabilities and improved efficiency, making them indispensable equipment in modern manufacturing processes.