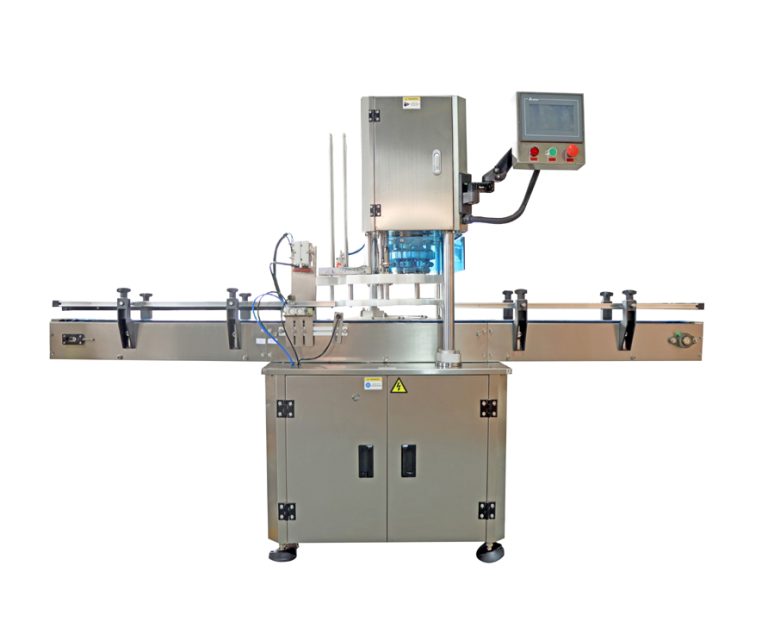

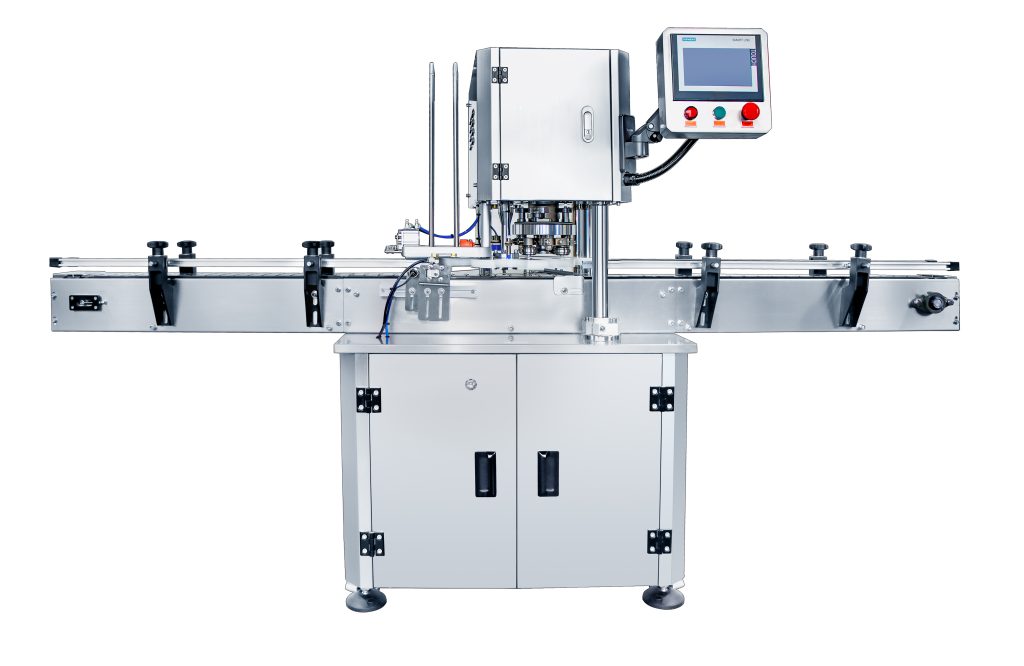

In the world of packaging, the advent of Automatic Servo Can Closing Machines has brought about a seismic shift, transforming the landscape in ways previously unimaginable.

These machines have redefined speed and efficiency. With their rapid and precise operations, they can seal a large number of cans in a fraction of the time it would take with traditional methods. This not only boosts production output but also meets the ever-growing demands of the market in a timely manner.

The level of accuracy achieved by Automatic Servo Can Closing Machines is unparalleled. They ensure that each can is sealed perfectly, eliminating the possibility of leaks or compromised seals. This leads to a significant reduction in product spoilage and waste, saving both resources and costs for businesses.

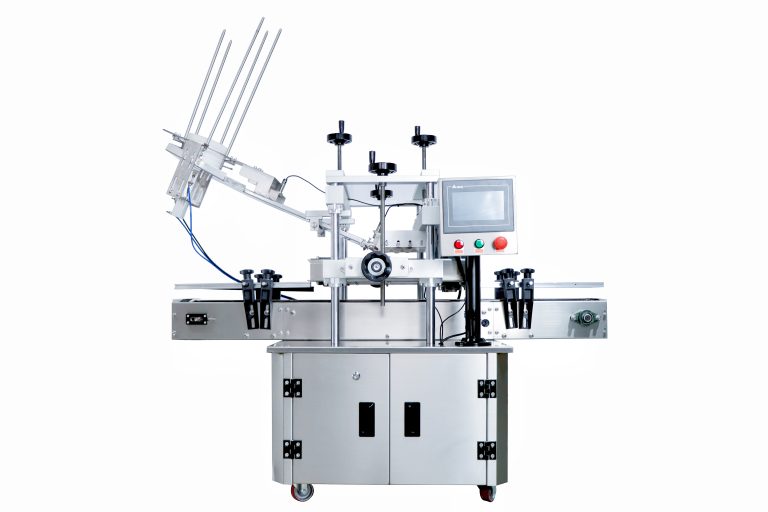

Another revolutionary aspect is their adaptability. These machines can handle a diverse range of can sizes and shapes, allowing for greater flexibility in packaging designs. This means companies can meet the specific needs of different products and consumers without having to invest in multiple specialized machines.

The integration of advanced technology also enables seamless monitoring and control. Operators can easily adjust settings and detect potential issues in real-time, minimizing downtime and maximizing productivity.

Furthermore, Automatic Servo Can Closing Machines contribute to a more sustainable packaging process. Their efficient use of materials and energy helps reduce the environmental impact of packaging operations.

In conclusion, Automatic Servo Can Closing Machines have truly revolutionized the packaging industry. They have set new standards for speed, accuracy, adaptability, and sustainability, shaping the future of how products are packaged and delivered to consumers.