Table of Contents

Benefits of Using an Automatic Three Side Square Bottle Labeling Machine

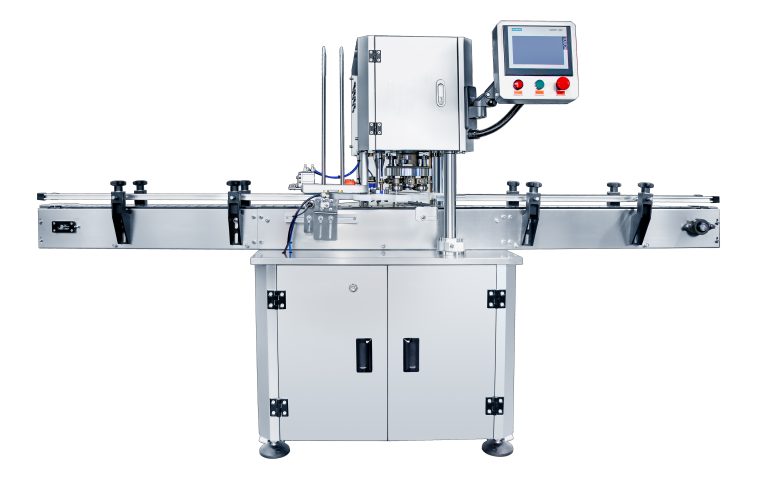

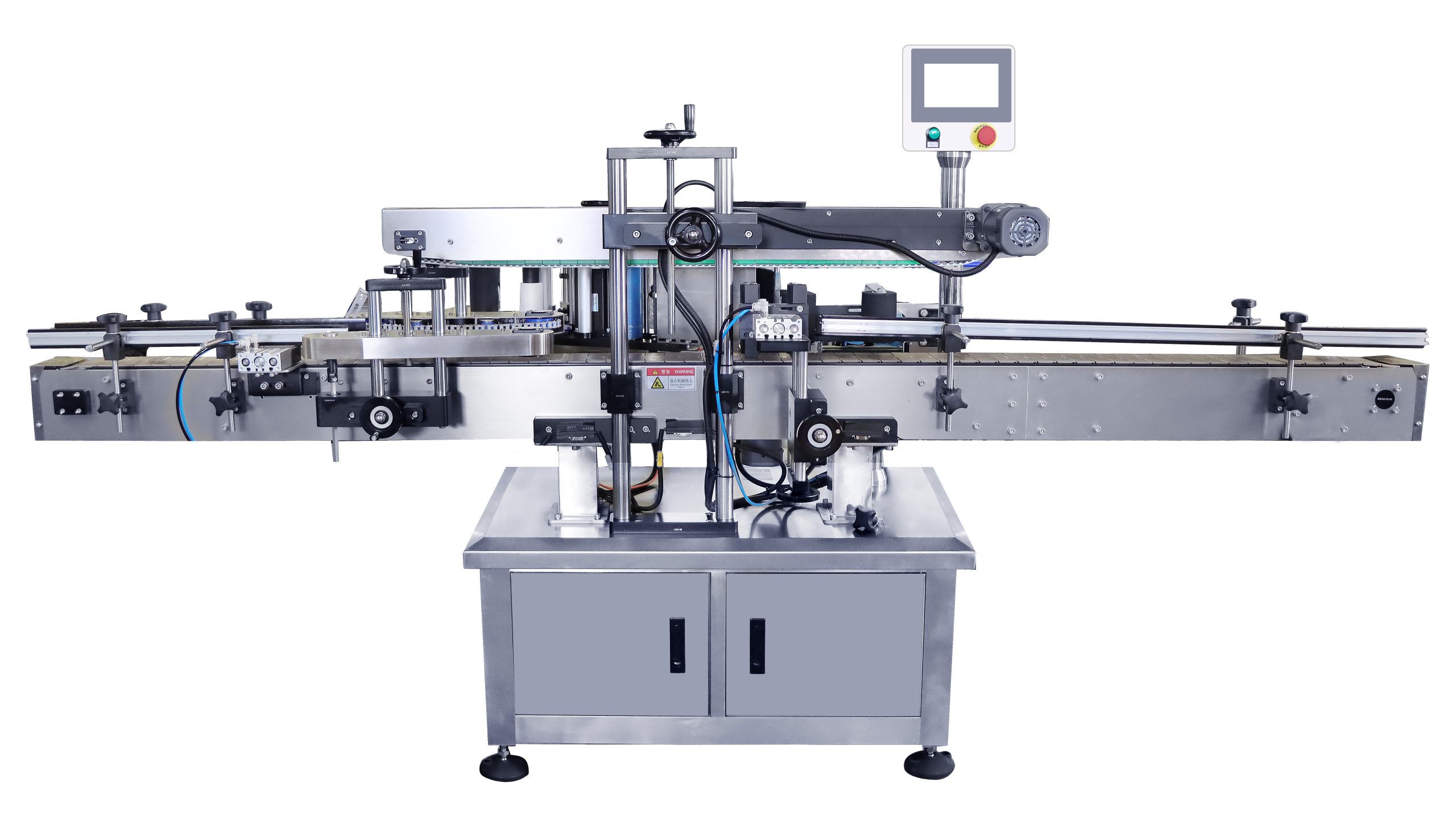

An automatic three side square bottle labeling machine is a valuable piece of equipment for businesses in various industries. This machine offers numerous benefits that can streamline the labeling process and improve efficiency. In this article, we will explore the advantages of using an automatic three side square bottle labeling machine.

One of the primary benefits of using an automatic three side square bottle labeling machine is its speed and accuracy. These machines are designed to apply labels to bottles quickly and precisely, ensuring that each bottle is labeled correctly every time. This can help businesses increase their production output and reduce the risk of errors in labeling.

Additionally, automatic three side square bottle labeling machines are versatile and can be used to label bottles of various shapes and sizes. This flexibility makes them ideal for businesses that produce a wide range of products and need a labeling solution that can adapt to different packaging requirements.

Another key benefit of using an automatic three side square bottle labeling machine is its ease of use. These machines are designed to be user-friendly, with intuitive controls and settings that make them easy to operate. This can help businesses save time and reduce the need for extensive training for employees who will be using the machine.

Furthermore, automatic three side square bottle labeling machines are highly efficient and can help businesses save money on labor costs. By automating the labeling process, businesses can reduce the need for manual labor and free up employees to focus on other tasks. This can lead to increased productivity and overall cost savings for the business.

In addition to improving efficiency and reducing costs, automatic three side square bottle labeling machines can also help businesses maintain a professional and consistent brand image. These machines are capable of applying labels with precision and accuracy, ensuring that each bottle is labeled in a uniform manner. This can help businesses create a cohesive and professional look for their products, which can enhance their brand reputation and customer perception.

Overall, the benefits of using an automatic three side square bottle labeling machine are numerous. From increased speed and accuracy to versatility and ease of use, these machines offer a range of advantages that can help businesses streamline their labeling process and improve efficiency. By investing in an automatic three side square bottle labeling machine, businesses can save time, reduce costs, and maintain a professional brand image.

How to Choose the Right Automatic Three Side Square Bottle Labeling Machine for Your Business

When it comes to labeling products, especially in industries such as pharmaceuticals, food and beverage, and cosmetics, having an efficient and accurate labeling machine is crucial. One popular option for labeling square bottles is the automatic three side square bottle labeling machine. This type of machine is designed to apply labels to three sides of a square bottle simultaneously, increasing efficiency and reducing labor costs. However, with so many options available on the market, it can be overwhelming to choose the right automatic three side square bottle labeling machine for your business. In this article, we will discuss some key factors to consider when selecting a labeling machine to ensure that you make the best choice for your specific needs.

First and foremost, it is important to consider the size and shape of the bottles that you will be labeling. Automatic three side square bottle labeling machines come in a variety of sizes and configurations to accommodate different bottle sizes and shapes. Make sure to choose a machine that is compatible with the dimensions of your bottles to ensure a proper fit and accurate labeling.

Another important factor to consider is the speed and efficiency of the labeling machine. Depending on the volume of bottles that you need to label, you may require a machine that can label a high number of bottles per minute. Look for a machine that offers adjustable speed settings to accommodate different production requirements.

In addition to speed, accuracy is also crucial when it comes to labeling products. Look for a labeling machine that offers precise label placement to ensure that your products are labeled correctly every time. Some machines come equipped with advanced sensors and technology to ensure accurate label placement, so be sure to inquire about these features when researching different machines.

Ease of use and maintenance are also important considerations when choosing an automatic three side square bottle labeling machine. Look for a machine that is user-friendly and easy to operate, with intuitive controls and clear instructions. Additionally, consider the maintenance requirements of the machine and choose one that is easy to clean and maintain to minimize downtime and ensure optimal performance.

Cost is another important factor to consider when selecting a labeling machine for your business. While it may be tempting to choose the cheapest option available, it is important to consider the long-term costs and benefits of the machine. Look for a machine that offers a good balance of quality and affordability, with a solid warranty and reliable customer support.

In conclusion, choosing the right automatic three side square bottle labeling machine for your business is a crucial decision that can have a significant impact on your production efficiency and overall success. By considering factors such as bottle size and shape, speed and efficiency, accuracy, ease of use and maintenance, and cost, you can make an informed decision that meets your specific labeling needs. Take the time to research different machines, compare features and prices, and consult with industry experts to ensure that you choose the best labeling machine for your business.

Tips for Maximizing Efficiency with an Automatic Three Side Square Bottle Labeling Machine

In the world of manufacturing and packaging, efficiency is key. One way to maximize efficiency in your production line is by utilizing an automatic three side square bottle labeling machine. These machines are designed to quickly and accurately apply labels to square bottles, saving time and reducing the risk of errors. However, simply having the machine is not enough to ensure maximum efficiency. There are several tips and best practices that can help you get the most out of your automatic labeling machine.

First and foremost, it is important to properly set up and calibrate your labeling machine. This includes ensuring that the machine is correctly aligned with the bottles and that the label applicator is set to the correct speed and pressure. Taking the time to properly calibrate your machine at the beginning will save you time and frustration in the long run.

Another important tip for maximizing efficiency with your automatic labeling machine is to regularly clean and maintain the machine. Dust, dirt, and debris can build up on the machine over time, leading to malfunctions and errors. By regularly cleaning and maintaining your machine, you can ensure that it continues to operate smoothly and efficiently.

In addition to regular maintenance, it is also important to use high-quality labels and adhesive. Low-quality labels can jam the machine or cause the labels to peel off prematurely, leading to wasted time and materials. By investing in high-quality labels and adhesive, you can ensure that your labels are applied accurately and securely every time.

One of the key benefits of an automatic labeling machine is its ability to label bottles quickly and accurately. To take full advantage of this benefit, it is important to properly train your employees on how to use the machine. This includes teaching them how to load labels and adjust settings, as well as how to troubleshoot common issues. By ensuring that your employees are properly trained, you can minimize downtime and maximize efficiency.

Another tip for maximizing efficiency with your automatic labeling machine is to batch similar jobs together. This means running all of your square bottle labeling jobs at the same time, rather than switching back and forth between different types of bottles. By batching similar jobs together, you can reduce setup time and increase overall productivity.

Finally, it is important to regularly monitor and analyze the performance of your automatic labeling machine. This includes tracking metrics such as labeling speed, error rates, and downtime. By regularly monitoring these metrics, you can identify areas for improvement and make adjustments to increase efficiency.

In conclusion, an automatic three side square bottle labeling machine can be a valuable asset in your production line. By following these tips and best practices, you can maximize efficiency and get the most out of your machine. Proper setup, maintenance, training, and monitoring are all key factors in ensuring that your automatic labeling machine operates at peak performance. By taking the time to implement these tips, you can streamline your production process and increase overall productivity.