Benefits of Using a 3% Residual Oxygen Automatic Canned Milk Powder Vacuum Nitrogen Filling Sealing Machine

In the food industry, ensuring the quality and freshness of products is of utmost importance. This is especially true for perishable items such as milk powder, which can easily spoil if exposed to oxygen. To address this issue, many manufacturers are turning to advanced packaging solutions, such as the 3% Residual Oxygen Automatic Canned Milk Powder Vacuum Nitrogen Filling Sealing Machine.

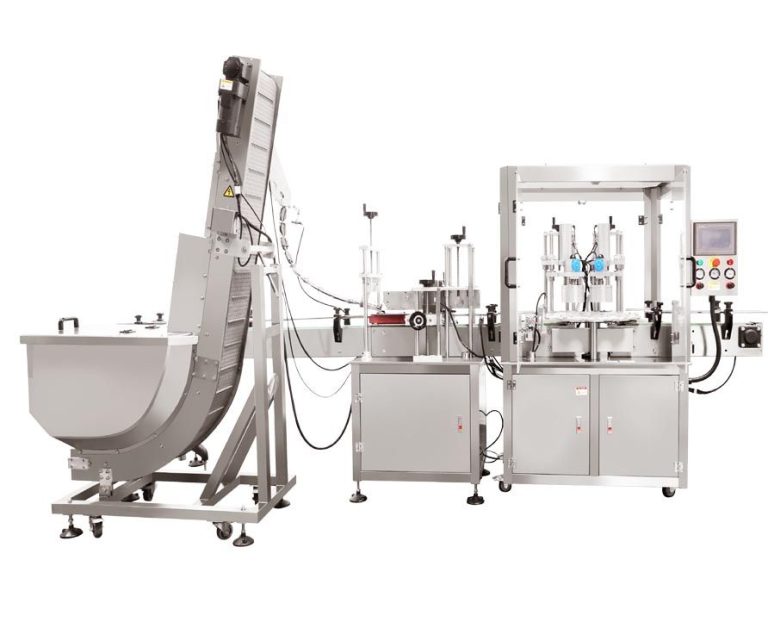

This cutting-edge machine is designed to automatically fill and seal cans of milk powder while maintaining a low oxygen environment. By vacuuming out the air from the cans and replacing it with nitrogen gas, the machine helps to extend the shelf life of the product and preserve its quality. Here are some of the key benefits of using a 3% Residual Oxygen Automatic Canned Milk Powder Vacuum Nitrogen Filling Sealing Machine.

First and foremost, this machine helps to prevent oxidation of the milk powder. When exposed to oxygen, milk powder can undergo chemical reactions that lead to off-flavors and spoilage. By removing the air from the cans and replacing it with nitrogen gas, the machine creates a protective barrier that helps to preserve the freshness and flavor of the product.

Additionally, the low oxygen environment created by the machine helps to inhibit the growth of bacteria and other microorganisms. This can help to extend the shelf life of the milk powder and reduce the risk of foodborne illnesses. By sealing the cans in a nitrogen-filled environment, manufacturers can ensure that their products remain safe for consumption for longer periods of time.

Another benefit of using a 3% Residual Oxygen Automatic Canned Milk Powder Vacuum Nitrogen Filling Sealing Machine is that it helps to maintain the nutritional value of the milk powder. Oxygen can degrade vitamins and other nutrients in food products, leading to a loss of nutritional quality. By minimizing the exposure of the milk powder to oxygen, the machine helps to preserve the vitamins and minerals in the product, ensuring that consumers receive the full nutritional benefits.

Furthermore, the machine is highly efficient and can significantly increase productivity in the packaging process. By automating the filling and sealing of cans, manufacturers can streamline their operations and reduce the need for manual labor. This can help to lower production costs and improve overall efficiency in the manufacturing process.

In conclusion, the 3% Residual Oxygen Automatic Canned Milk Powder Vacuum Nitrogen Filling Sealing Machine offers a range of benefits for manufacturers in the food industry. From preserving the quality and freshness of milk powder to extending its shelf life and maintaining its nutritional value, this advanced packaging solution is a valuable asset for any food production facility. By investing in this machine, manufacturers can improve the quality of their products, reduce waste, and increase efficiency in their operations.