It seems we can’t find what you’re looking for. Perhaps searching can help.

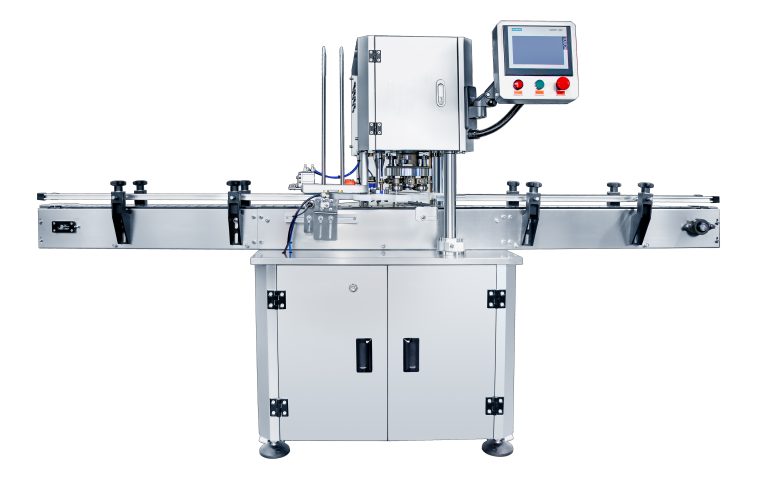

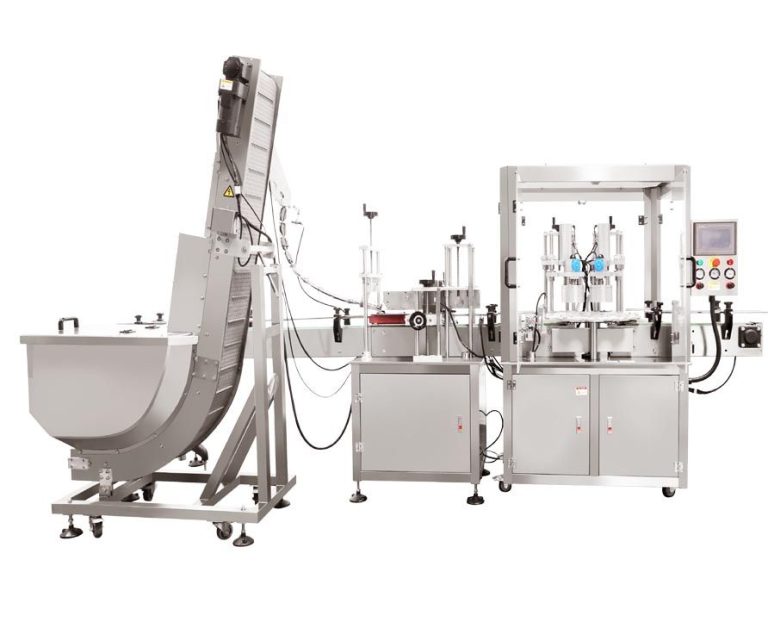

“What is an Automatic Dual-Head Servo Can Seaming Machine and How Does It Work?”

An automatic dual-head servo can seaming machine is a sophisticated piece of equipment designed for efficient and precise sealing of cans. It works through a complex yet highly coordinated process. At its core, the machine has two seaming heads that operate simultaneously. The cans are placed in position, and a…