It seems we can’t find what you’re looking for. Perhaps searching can help.

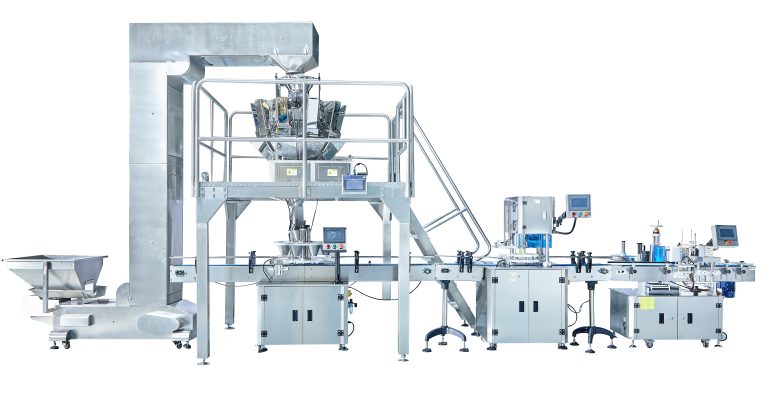

“Enhancing Quality Control in Automatic Canned Granules Packaging”

In the realm of automatic canned granules packaging, ensuring superior quality control is of utmost significance. The process demands meticulous attention to detail and the implementation of effective strategies to guarantee the end products meet the highest standards. To enhance quality control, advanced inspection systems are integrated into the packaging…