Table of Contents

Benefits of Using a Semi Automatic Vacuum Can Seamer with Gas Flushing

In the food packaging industry, ensuring the quality and freshness of products is of utmost importance. One way to achieve this is by using a semi-automatic vacuum can seamer with gas flushing. This innovative technology offers numerous benefits that can help improve the overall efficiency and quality of the packaging process.

One of the key benefits of using a semi-automatic vacuum can seamer with gas flushing is the ability to extend the shelf life of products. By removing air from the can and replacing it with a gas such as nitrogen or carbon dioxide, the seamer creates a modified atmosphere that helps preserve the freshness of the contents. This can be particularly beneficial for products that are sensitive to oxygen and moisture, such as coffee, nuts, and snacks.

In addition to extending shelf life, a semi-automatic vacuum can seamer with gas flushing also helps maintain the quality and flavor of the products. By minimizing exposure to oxygen, the seamer helps prevent oxidation and rancidity, which can lead to off-flavors and spoilage. This is especially important for products that are prone to degradation over time, such as oils, sauces, and condiments.

Another advantage of using a semi-automatic vacuum can seamer with gas flushing is the ability to improve the overall appearance of the packaging. By removing air from the can, the seamer helps create a tight seal that enhances the visual appeal of the product. This can be particularly important for products that are marketed based on their appearance, such as gourmet foods and specialty items.

Furthermore, a semi-automatic vacuum can seamer with gas flushing can help reduce the risk of contamination and spoilage. By creating a controlled environment inside the can, the seamer helps prevent the growth of bacteria and other microorganisms that can cause foodborne illnesses. This can be especially important for products that are consumed raw or have a high risk of contamination, such as seafood, meats, and dairy products.

Additionally, using a semi-automatic vacuum can seamer with gas flushing can help improve the overall efficiency of the packaging process. By automating the sealing and gas flushing process, the seamer helps reduce the need for manual labor and streamlines production. This can help save time and labor costs, while also ensuring consistent and reliable results.

Overall, the benefits of using a semi-automatic vacuum can seamer with gas flushing are numerous and can have a significant impact on the quality, freshness, and efficiency of the packaging process. By extending shelf life, maintaining product quality, enhancing appearance, reducing contamination risks, and improving efficiency, this innovative technology offers a valuable solution for food packaging companies looking to enhance their products and meet consumer demands for quality and freshness.

Step-by-Step Guide on How to Operate a Semi Automatic Vacuum Can Seamer with Gas Flushing

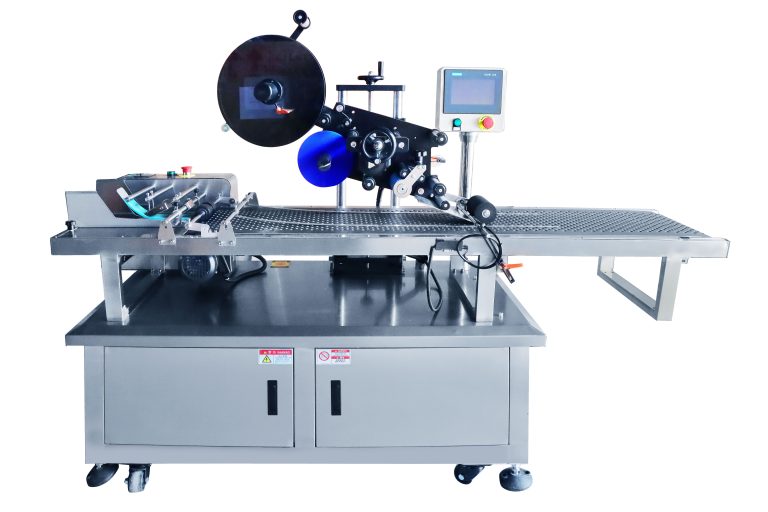

A semi-automatic vacuum can seamer with gas flushing is a valuable piece of equipment for businesses looking to extend the shelf life of their canned products. This machine is designed to create a vacuum seal in cans while also injecting a gas, such as nitrogen or carbon dioxide, to help preserve the contents. Operating this machine requires precision and attention to detail to ensure that the cans are properly sealed and preserved.

To begin operating a semi-automatic vacuum can seamer with gas flushing, the first step is to ensure that the machine is properly set up and calibrated. This includes checking that the gas supply is connected and that the vacuum pump is functioning correctly. It is also important to make sure that the seaming rollers are adjusted to the correct height for the size of cans being used.

Once the machine is set up, the next step is to load the cans onto the conveyor belt. It is important to make sure that the cans are properly aligned and spaced out to ensure that they are sealed correctly. The cans should be fed into the machine one at a time to prevent jams and ensure that each can is sealed properly.

As the cans move through the machine, the vacuum seaming process begins. The vacuum pump removes the air from inside the can, creating a vacuum seal. At the same time, the gas flushing system injects a small amount of gas into the can to help preserve the contents. This process helps to extend the shelf life of the canned products and maintain their freshness.

As the cans are sealed, it is important to monitor the machine for any issues or malfunctions. If a can does not seal properly, it should be removed from the line and resealed manually. It is also important to check the gas levels and adjust the gas flushing system as needed to ensure that the correct amount of gas is being injected into each can.

Once all of the cans have been sealed and flushed with gas, they can be removed from the machine and stacked for storage or distribution. It is important to handle the cans carefully to avoid damaging the seals and compromising the preservation of the contents. The sealed cans should be stored in a cool, dry place away from direct sunlight to maintain their freshness.

In conclusion, operating a semi-automatic vacuum can seamer with gas flushing requires attention to detail and precision to ensure that the cans are properly sealed and preserved. By following the steps outlined in this guide, businesses can extend the shelf life of their canned products and maintain their quality for longer periods. With proper maintenance and care, a semi-automatic vacuum can seamer with gas flushing can be a valuable asset for businesses looking to preserve their products and meet the demands of their customers.

-768x622.jpg)