In this comprehensive guide, we’ll explore everything you need to know about semi-automatic vacuum capping machines.

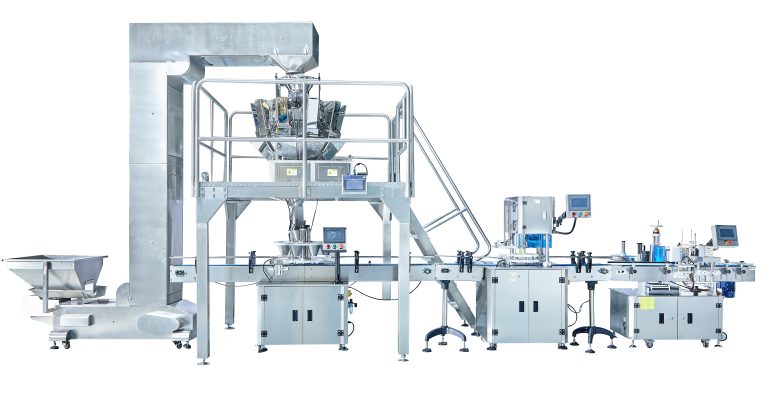

Semi-automatic vacuum capping machines are essential tools in various industries, offering a balance between efficiency and manual control. These machines are designed to create a vacuum within containers and seal them securely to preserve the contents.

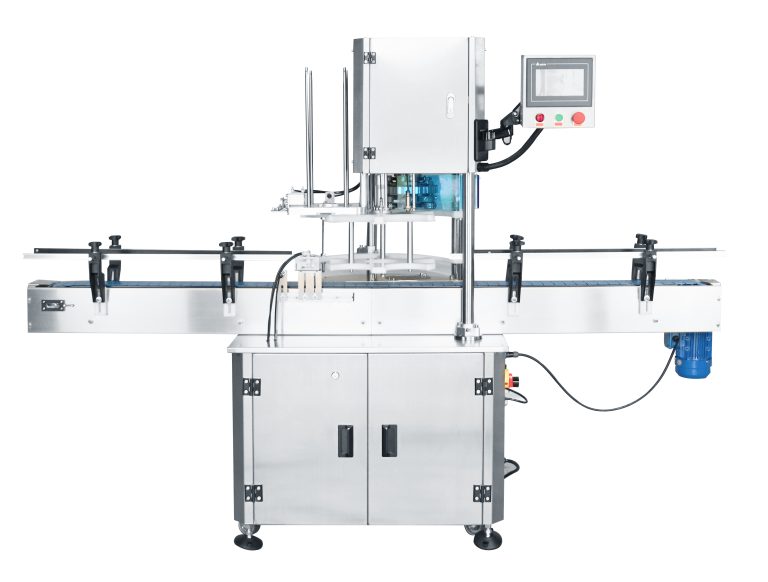

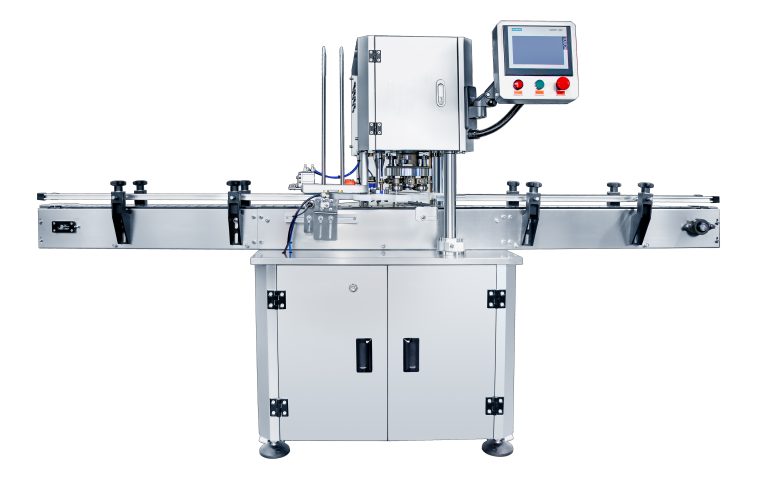

Let’s start by understanding the key components of a semi-automatic vacuum capping machine. The main elements include a vacuum pump for evacuating air, a capping mechanism to attach the lids or caps, and a control system that allows operators to manage the process.

One of the significant advantages of these machines is their flexibility. They can handle a wide range of container sizes and shapes, making them suitable for diverse products. This adaptability is crucial for businesses that deal with multiple packaging formats.

When it comes to operation, training is relatively straightforward. Operators need to be familiar with loading the containers, initiating the vacuum process, and positioning the caps correctly. With a little practice, productivity can be maximized.

Maintenance is an important aspect to consider. Regular checks of the vacuum pump, seals, and mechanical parts ensure the machine’s reliable performance and longevity.

Semi-automatic vacuum capping machines also offer cost-effectiveness compared to fully automatic models. They are an ideal choice for businesses with moderate production volumes or those that require more hands-on control during the capping process.

In conclusion, a semi-automatic vacuum capping machine can be a game-changer for your packaging operations. By understanding its features, benefits, and proper usage, you can make an informed decision and optimize your production workflow.