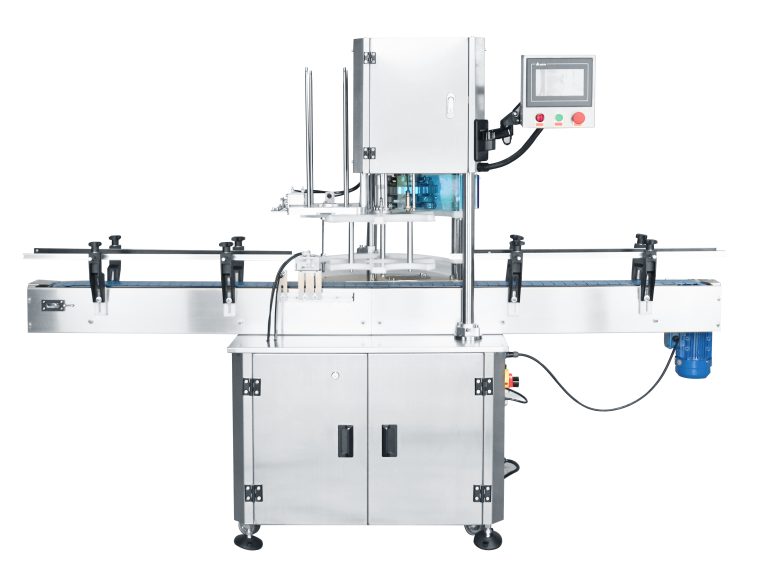

In the world of jam production, the semi-automatic vacuum glass jar capping machine plays a crucial role.

This specialized machine offers several significant benefits for preserving the deliciousness and longevity of homemade or commercial jams. The vacuum sealing feature is a standout. By removing the air from inside the glass jars, it helps prevent oxidation and the growth of microorganisms, allowing the jam to stay fresh for longer periods.

The semi-automatic operation provides a balance between efficiency and control. It allows operators to have a certain level of oversight and intervention during the capping process, which can be especially important when dealing with delicate or handcrafted jams.

The machine is designed to handle the specific requirements of glass jars, ensuring a tight and secure seal. This not only protects the jam from spoilage but also enhances the presentation of the final product on store shelves or in pantries.

One of the key advantages of this capping machine is its adaptability. It can be used for a variety of jar sizes and shapes, giving producers the flexibility to offer different packaging options to meet consumer demands.

The semi-automatic nature also makes it more accessible and manageable for smaller-scale jam producers or those who value a hands-on approach to their production process.

Maintenance of the machine is relatively straightforward, and with proper care and cleaning, it can provide reliable service for an extended period.

In conclusion, the semi-automatic vacuum glass jar capping machine for jam is an essential tool for jam makers who are committed to delivering high-quality, fresh, and delicious products to their customers.

Stay tuned to our blogs for more detailed insights and tips on jam production and packaging!