Похоже, мы не можем найти то, что вы запрашиваете. Возможно, поможет поиск.

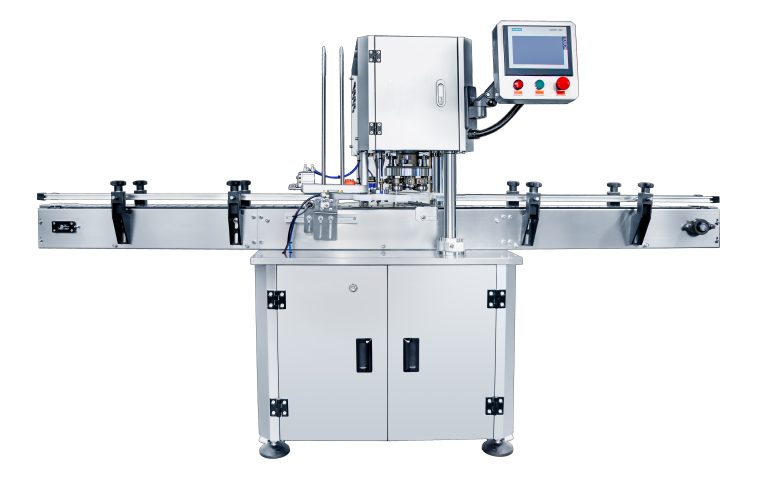

“How Automatic Servo Can Closing Machines Revolutionize Packaging”

In the world of packaging, the advent of Automatic Servo Can Closing Machines has brought about a seismic shift, transforming the landscape in ways previously unimaginable. These machines have redefined speed and efficiency. With their rapid and precise operations, they can seal a large number of cans in a fraction…