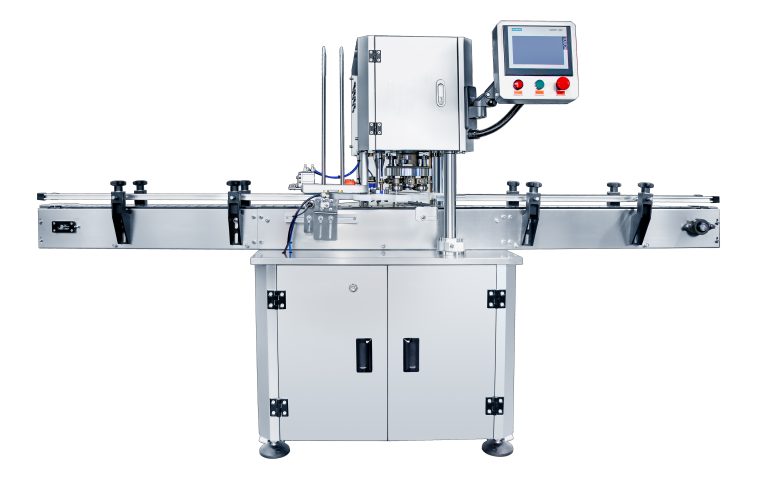

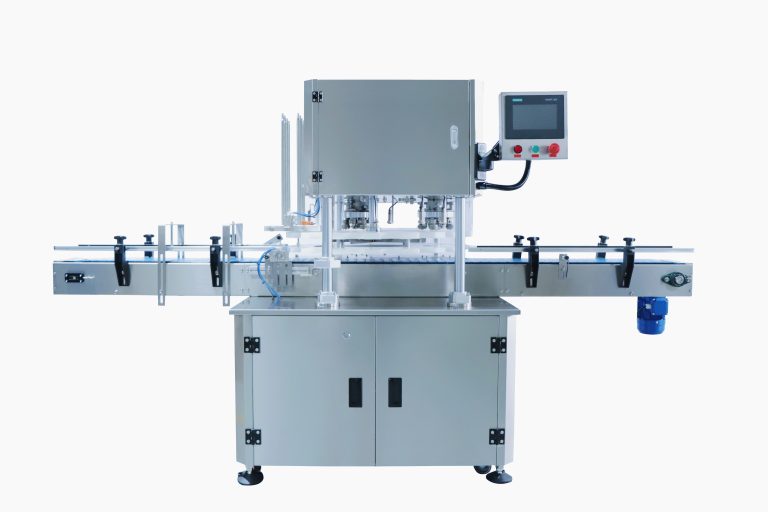

Single-head servo cappers bring about a notable enhancement in both efficiency and precision through several key aspects.

The precision of single-head servo cappers is primarily achieved through the advanced servo technology. This technology enables precise control over the capping torque and pressure, ensuring that each cap is applied with exactness. The result is a consistently tight and secure fit, minimizing the risk of leaks or improper closures.

In terms of efficiency, the focused operation of a single-head capper allows for quick and seamless capping of each container. There are no delays or interruptions associated with multiple heads, leading to a streamlined process.

The speed of the capping action can be adjusted and optimized based on the specific requirements of the production line. This adaptability ensures that the capper keeps pace with the overall production speed, maximizing output.

The single-head design also simplifies maintenance and troubleshooting. Any issues can be identified and resolved more quickly, reducing downtime and enhancing the machine’s availability for productive work.

The integration of intelligent control systems in single-head servo cappers enables real-time monitoring and adjustment. This allows for immediate correction of any deviations in the capping process, maintaining high levels of efficiency and precision.

Moreover, the consistent performance of these cappers eliminates the need for rework or quality checks on capped containers, saving valuable time and resources.

In summary, the combination of precise control, focused operation, adaptability, easy maintenance, and intelligent monitoring makes single-head servo cappers highly efficient and precise, contributing significantly to the smooth and productive operation of packaging lines.