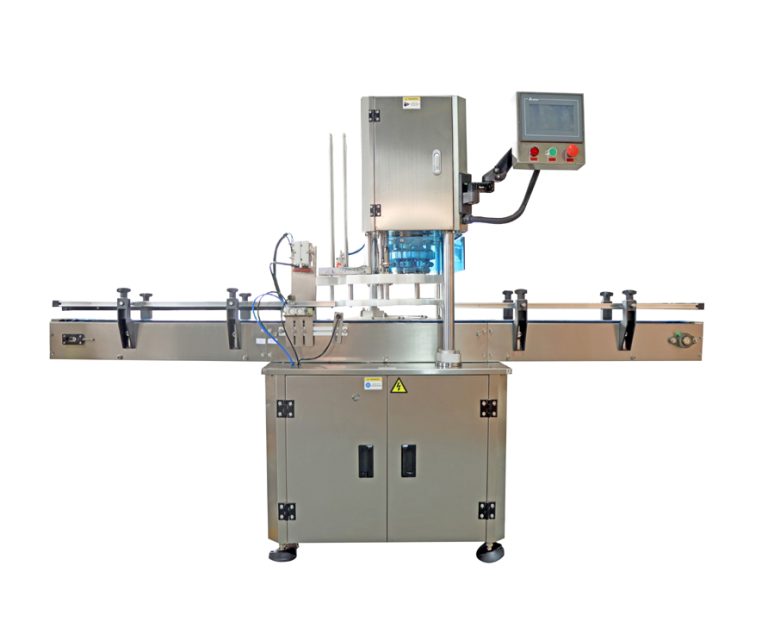

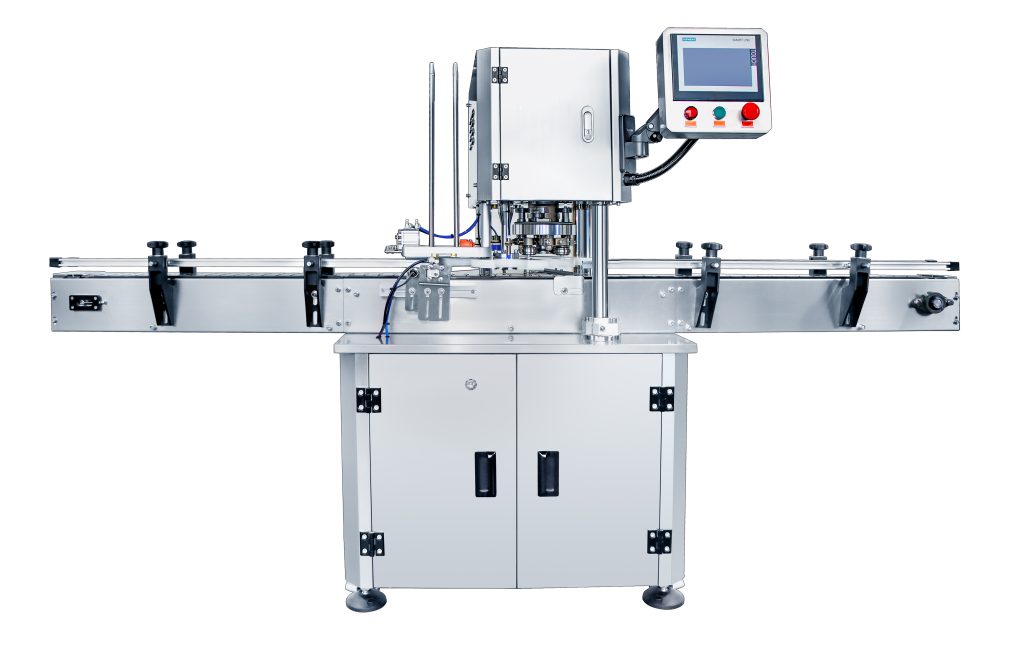

Automatic servo can seamers have brought about a remarkable transformation in the world of can sealing.

These advanced machines offer unprecedented levels of precision and accuracy. The servo technology ensures that each can is sealed with exact force and alignment, eliminating variations and reducing the risk of leaks or faulty seals.

They significantly increase the speed of the sealing process. With their rapid and efficient operation, production lines can handle larger volumes of cans in a shorter time, boosting overall productivity.

The automation aspect reduces the reliance on manual labor. This not only saves costs but also minimizes human errors that can occur during the sealing process.

Automatic servo can seamers are highly adaptable. They can easily handle different can sizes, shapes, and materials, allowing manufacturers to switch between products seamlessly.

The quality of the seals is consistently superior. This leads to better product preservation, longer shelf life, and increased customer satisfaction.

The machines also come equipped with advanced monitoring and control systems. These systems provide real-time data on the sealing process, enabling operators to identify and address any issues promptly.

In conclusion, automatic servo can seamers have revolutionized can sealing processes by enhancing efficiency, quality, adaptability, and control, making them an indispensable tool in modern manufacturing.