The world of packaging is filled with remarkable innovations, and semi-automatic can seamer machines are among the hidden gems that deserve our exploration.

These machines are a testament to human ingenuity and engineering prowess. At first glance, they might seem like simple pieces of equipment, but upon closer inspection, their complexity and functionality are truly astonishing.

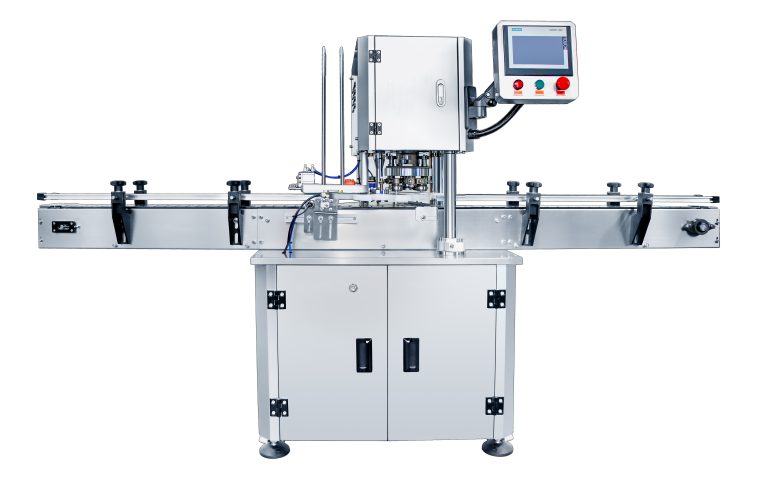

The precision with which semi-automatic can seamer machines operate is nothing short of extraordinary. They ensure that each can is sealed with absolute accuracy, leaving no room for leaks or compromised integrity. This level of precision is crucial in maintaining the quality and safety of the contents within the cans.

The speed at which they work is another wonder. In a matter of seconds, cans are seamlessly sealed, ready for distribution. This efficiency not only saves time but also boosts productivity, allowing businesses to meet the ever-growing demands of the market.

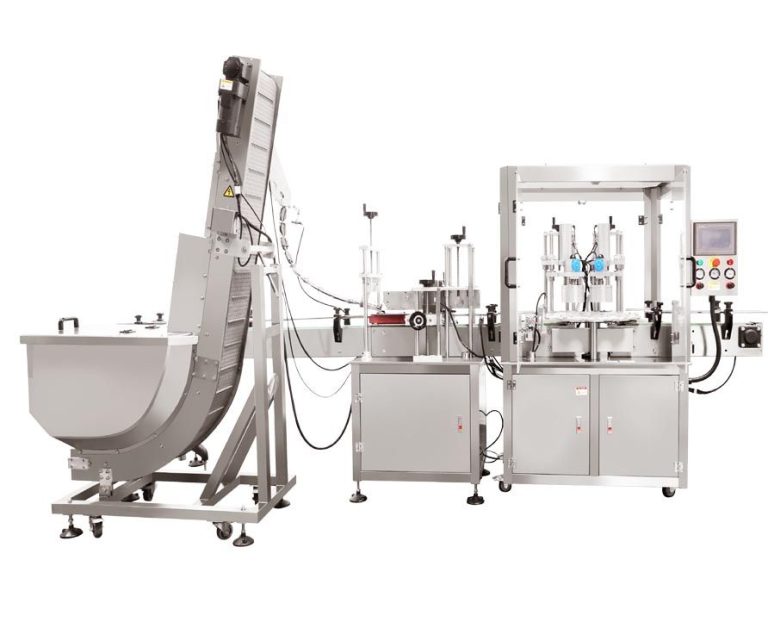

The adaptability of these machines is yet another aspect that sets them apart. They can handle a wide range of can sizes and materials, making them versatile tools in various industries.

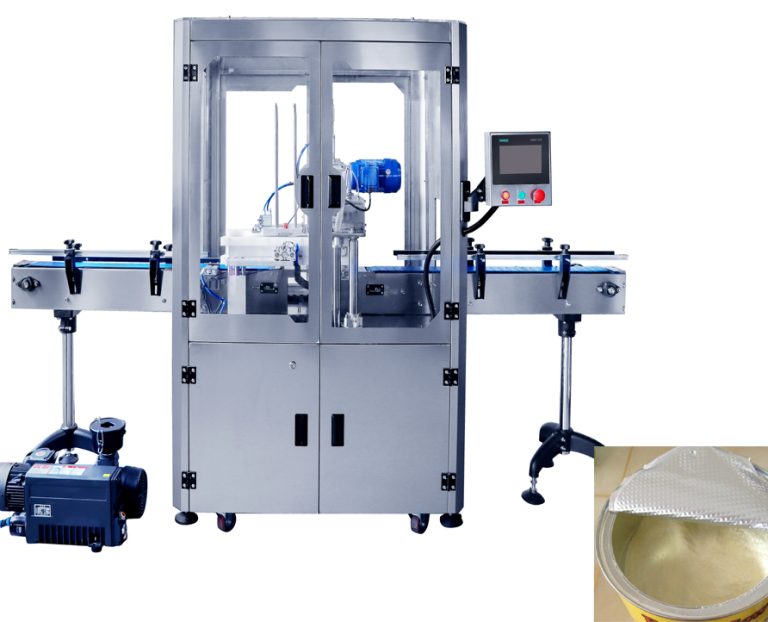

The user interface is designed for ease of operation, enabling operators to control the process effortlessly. Even with their semi-automatic nature, they offer a level of control that ensures consistent results.

Maintenance of these machines is relatively straightforward, thanks to their well-thought-out design. Regular servicing keeps them in top condition, ensuring long-term reliability.

In conclusion, unraveling the wonders of semi-automatic can seamer machines reveals their indispensable role in the packaging industry. They combine precision, speed, adaptability, and user-friendliness to deliver exceptional performance and contribute significantly to the seamless flow of goods in the marketplace.