Table of Contents

Benefits of Using Automatic Dustproof Lid Capper Equipment

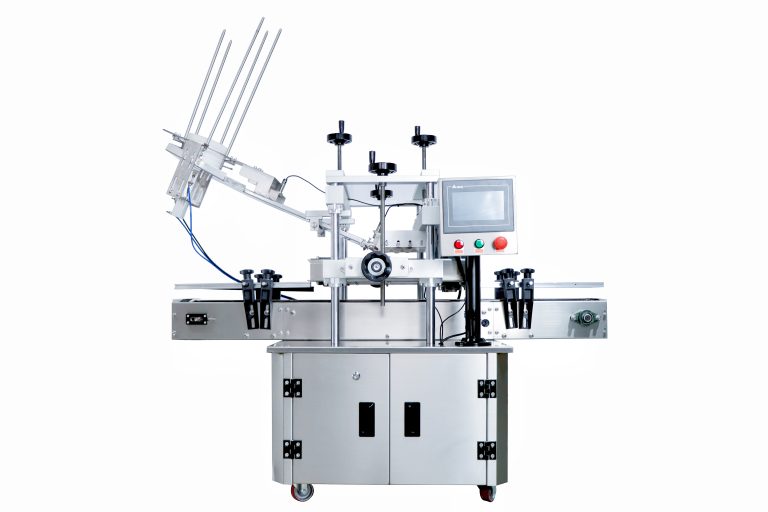

Automatic dustproof lid capper equipment is a valuable tool for businesses looking to streamline their packaging process and ensure the quality of their products. These machines are designed to automatically cap containers with dustproof lids, providing a secure seal that protects the contents from contamination and spoilage. There are several benefits to using automatic dustproof lid capper equipment, making it a wise investment for companies in various industries.

One of the primary benefits of using automatic dustproof lid capper equipment is the efficiency it brings to the packaging process. These machines are capable of capping containers at a much faster rate than manual labor, saving businesses time and labor costs. With automatic dustproof lid capper equipment, companies can increase their production output and meet customer demand more effectively.

In addition to efficiency, automatic dustproof lid capper equipment also helps improve the overall quality of the packaging. These machines are designed to cap containers with precision, ensuring a tight and secure seal that prevents dust and other contaminants from entering the container. This helps maintain the freshness and quality of the product, extending its shelf life and reducing the risk of spoilage.

Furthermore, automatic dustproof lid capper equipment is easy to operate and requires minimal training. This makes it an ideal solution for businesses looking to streamline their packaging process without investing in extensive training for their employees. With user-friendly controls and simple setup, these machines can be integrated seamlessly into existing production lines, making them a cost-effective solution for businesses of all sizes.

Another benefit of using automatic dustproof lid capper equipment is the versatility it offers. These machines are capable of capping containers of various shapes and sizes, making them suitable for a wide range of products. Whether you are packaging food, beverages, pharmaceuticals, or cosmetics, automatic dustproof lid capper equipment can help you achieve a secure and professional seal on your containers.

Additionally, automatic dustproof lid capper equipment is designed to be durable and reliable, ensuring consistent performance over time. These machines are built to withstand the rigors of daily use in a production environment, making them a long-term investment for businesses looking to improve their packaging process. With regular maintenance and proper care, automatic dustproof lid capper equipment can provide years of reliable service, helping businesses save money on repairs and replacements.

In conclusion, automatic dustproof lid capper equipment offers numerous benefits for businesses looking to improve their packaging process. From increased efficiency and quality to ease of operation and versatility, these machines are a valuable tool for companies in various industries. By investing in automatic dustproof lid capper equipment, businesses can streamline their production process, protect the quality of their products, and ultimately improve their bottom line.

How to Choose the Right Automatic Dustproof Lid Capper Equipment for Your Needs

When it comes to choosing the right automatic dustproof lid capper equipment for your needs, there are several factors to consider. From the size and speed of the machine to the type of lids it can cap, it’s important to do your research and make an informed decision. In this article, we will discuss some of the best choices of automatic dustproof lid capper equipment on the market today.

One of the top choices for automatic dustproof lid capper equipment is the XYZ Model 5000. This machine is known for its high speed and efficiency, capable of capping up to 100 lids per minute. It is also versatile, able to cap a wide range of lid sizes and shapes. The XYZ Model 5000 is a popular choice among manufacturers who need a reliable and fast capping solution.

Another great option is the ABC Model 3000. This machine is known for its durability and reliability, making it a great choice for manufacturers who need a capper that can withstand heavy use. The ABC Model 3000 is also easy to operate, with a user-friendly interface that makes it simple to adjust settings and change out lids. This machine is a great choice for manufacturers who need a dependable capping solution.

For manufacturers who need a more compact capping solution, the DEF Model 2000 is a great choice. This machine is smaller in size but still packs a punch when it comes to capping lids. The DEF Model 2000 is known for its precision and accuracy, making it a great choice for manufacturers who need a capper that can handle delicate lids with ease. This machine is also easy to clean and maintain, making it a great choice for manufacturers who need a low-maintenance capping solution.

When choosing the right automatic dustproof lid capper equipment for your needs, it’s important to consider the size and speed of the machine, as well as the type of lids it can cap. It’s also important to consider the durability and reliability of the machine, as well as how easy it is to operate and maintain. By doing your research and considering these factors, you can choose the best automatic dustproof lid capper equipment for your manufacturing needs.

In conclusion, there are several great choices of automatic dustproof lid capper equipment on the market today. From high-speed machines like the XYZ Model 5000 to compact and precise machines like the DEF Model 2000, there is a capping solution for every manufacturing need. By considering factors like size, speed, and versatility, you can choose the right automatic dustproof lid capper equipment for your needs. Make sure to do your research and choose a machine that will help you streamline your manufacturing process and improve efficiency.

Top Features to Look for in Automatic Dustproof Lid Capper Equipment

When it comes to packaging products, ensuring that lids are securely sealed is crucial to maintaining product quality and preventing contamination. Automatic dustproof lid capper equipment is a valuable tool for businesses looking to streamline their packaging process and ensure that lids are properly sealed every time. With so many options available on the market, it can be overwhelming to choose the best equipment for your needs. In this article, we will discuss the top features to look for in automatic dustproof lid capper equipment to help you make an informed decision.

One of the most important features to consider when choosing automatic dustproof lid capper equipment is speed and efficiency. Look for equipment that can cap lids quickly and accurately to keep up with your production demands. High-speed equipment can help you increase productivity and reduce bottlenecks in your packaging process. Additionally, look for equipment that is easy to set up and adjust to minimize downtime and ensure smooth operation.

Another important feature to consider is the versatility of the equipment. Choose equipment that can cap a variety of lid sizes and types to accommodate different products. This will allow you to use the equipment for a wide range of packaging needs without having to invest in multiple machines. Versatile equipment can also help you save space in your facility and reduce costs associated with purchasing and maintaining multiple machines.

Durability is also a key factor to consider when choosing automatic dustproof lid capper equipment. Look for equipment that is built to last and can withstand the rigors of daily use in a production environment. High-quality materials and construction will ensure that your equipment remains reliable and efficient for years to come. Additionally, consider the reputation of the manufacturer and read reviews from other customers to ensure that you are investing in a reliable and durable product.

Ease of maintenance is another important feature to look for in automatic dustproof lid capper equipment. Choose equipment that is easy to clean and maintain to keep it running smoothly and prevent downtime. Look for equipment with accessible components and clear maintenance instructions to make it easy for your staff to perform routine maintenance tasks. Regular maintenance will help prolong the life of your equipment and ensure that it continues to operate at peak performance.

Finally, consider the overall cost of the equipment, including upfront costs, ongoing maintenance, and potential savings in labor and materials. While it may be tempting to choose the cheapest option, it is important to consider the long-term value of the equipment. Investing in high-quality equipment may cost more upfront but can save you money in the long run by reducing downtime, increasing productivity, and minimizing waste.

In conclusion, choosing the best automatic dustproof lid capper equipment for your business requires careful consideration of key features such as speed, versatility, durability, ease of maintenance, and overall cost. By taking the time to research and compare different options, you can find the equipment that best meets your needs and helps you improve your packaging process. Investing in high-quality equipment will not only benefit your business in the short term but also in the long term by improving efficiency, productivity, and product quality.