It seems we can’t find what you’re looking for. Perhaps searching can help.

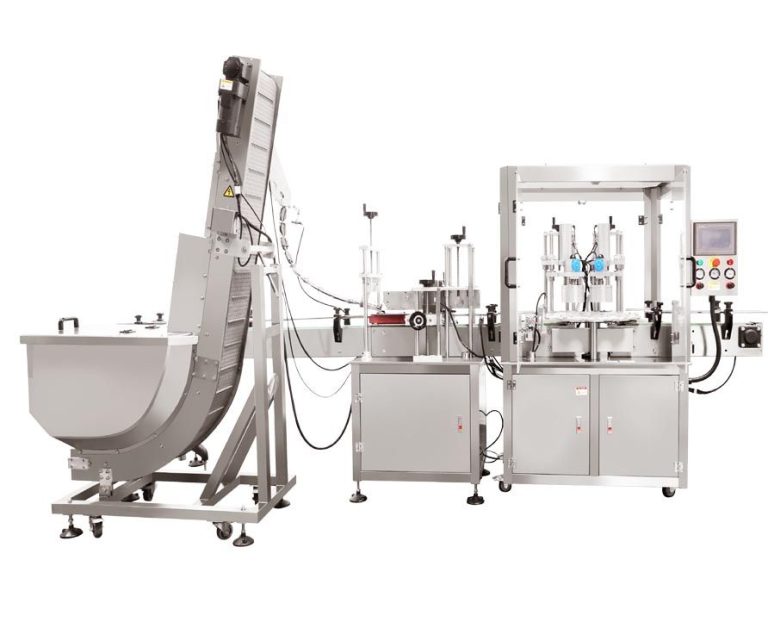

How the Automatic 8 Wheels Screw Capping Machine Transforms Packaging

In the realm of packaging, the automatic 8 wheels screw capping machine stands as a remarkable innovation that has brought about a paradigm shift in the way products are sealed. This advanced piece of equipment has transformed the packaging process in numerous ways, enhancing efficiency, quality, and overall productivity. 1….