It seems we can’t find what you’re looking for. Perhaps searching can help.

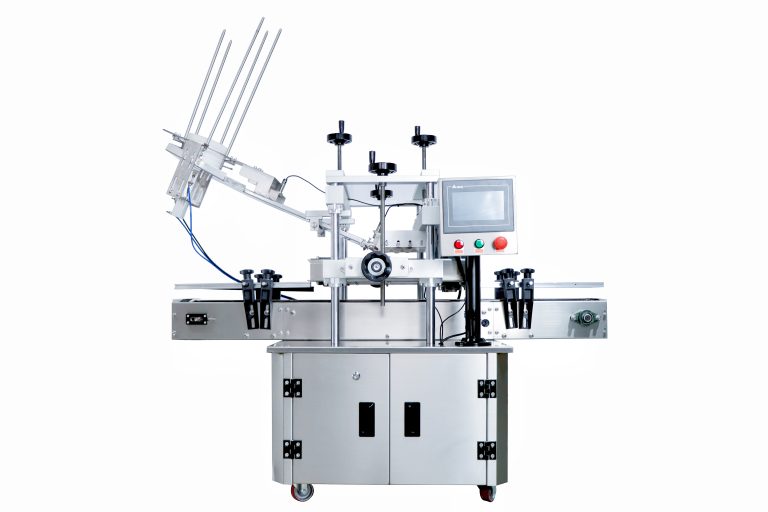

Semi automatic single chamber vacuum nitrogen flushing tin can seamer machine

Benefits of Using Semi Automatic Single Chamber Vacuum Nitrogen Flushing Tin Can Seamer Machine In the food packaging industry, efficiency and quality are key factors in ensuring that products reach consumers in optimal condition. One machine that has revolutionized the packaging process is the semi-automatic single chamber vacuum nitrogen flushing…

-768x622.jpg)