In the era of Industry 4.0, smart manufacturing has emerged as a revolutionary concept that is transforming the industrial landscape. Automatic glass bottle vacuum capping machines are at the forefront of this transformation, integrating advanced technologies to enhance efficiency, quality, and flexibility in the packaging process.

Table of Contents

The Foundation of Smart Manufacturing in Capping Machines

Automation and Robotics

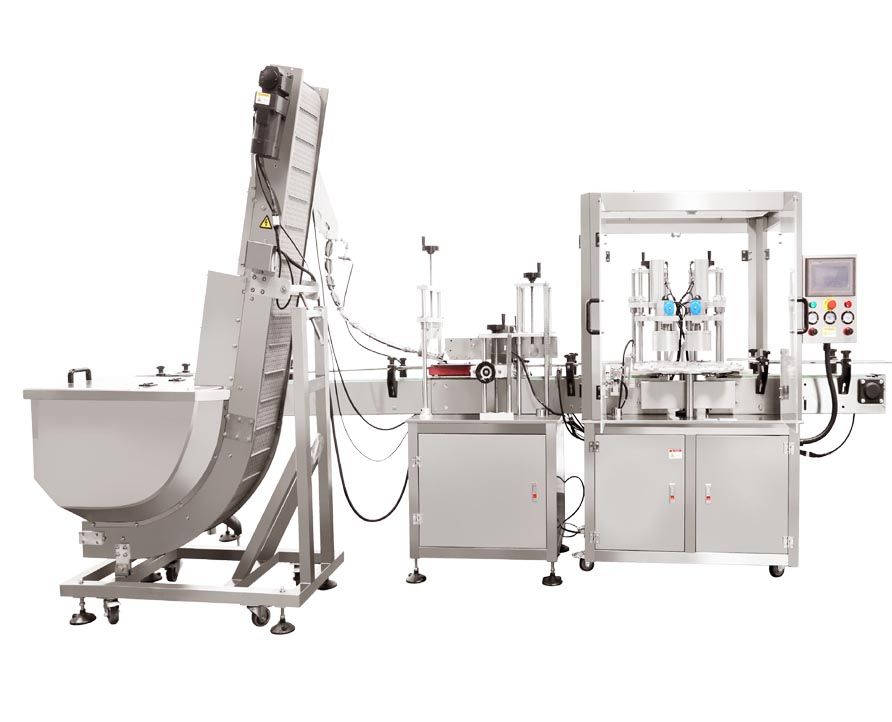

Automatic glass bottle vacuum capping machines are equipped with sophisticated automation systems. Robotic arms precisely handle the glass bottles, moving them through the filling and capping process with high speed and accuracy. These robots can be programmed to perform complex tasks, such as adjusting the position of the bottles based on their size and shape. For example, in a production line that packages different types of glass bottles, the robotic arms can quickly adapt to the variations, ensuring a seamless capping operation.

Sensor Technology

Sensors play a crucial role in the smart functioning of these machines. Optical sensors can detect the presence and position of the glass bottles, ensuring that they are correctly aligned for capping. Pressure sensors monitor the vacuum level inside the bottles, guaranteeing that the optimal vacuum is achieved for a tight seal. Temperature sensors can also be incorporated to ensure that the capping process occurs under the right environmental conditions, which is especially important for products that are sensitive to temperature changes.

Data Analytics

The data collected by the sensors in automatic glass bottle vacuum capping machines is analyzed in real – time. This data analytics allows manufacturers to monitor the performance of the machines, identify potential issues, and make proactive adjustments. For instance, if the data shows a consistent drop in the vacuum level for a particular batch of bottles, it could indicate a problem with the vacuum pump. By analyzing this data, maintenance teams can be alerted before the issue leads to a significant production disruption.

Benefits of Smart Manufacturing in Capping Machines

Enhanced Efficiency

Smart automatic glass bottle vacuum capping machines can operate at much higher speeds compared to traditional machines. The automation and real – time monitoring enable continuous production with minimal downtime. For example, if a machine detects a faulty bottle or cap, it can quickly eject it from the production line without stopping the entire process. This results in a significant increase in the number of bottles that can be capped per hour, improving overall productivity.

Improved Quality Control

The integration of sensors and data analytics ensures consistent quality in the capping process. Every bottle is inspected for proper vacuum levels, cap placement, and seal integrity. Any bottles that do not meet the quality standards are automatically rejected. This reduces the number of defective products reaching the market, enhancing customer satisfaction and brand reputation.

Flexibility and Customization

Smart capping machines can be easily reconfigured to handle different bottle sizes, shapes, and cap types. With the use of advanced programming, manufacturers can switch between production runs for various products quickly. For example, a company that produces both small perfume bottles and large beverage bottles can use the same automatic glass bottle vacuum capping machine by simply adjusting the settings through the control system.

Future Trends in Smart Capping Machines

Integration with the Internet of Things (IoT)

In the future, automatic glass bottle vacuum capping machines are likely to be fully integrated with the IoT. This means that they can communicate with other machines in the production line, as well as with central management systems. For example, the capping machine can send data about its performance and status to a cloud – based platform, where it can be accessed by managers and technicians from anywhere in the world. This remote monitoring and control will enable more efficient production management and faster response to any issues.

Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms will be increasingly used in smart capping machines. These technologies can analyze large amounts of data collected over time to predict maintenance needs, optimize the capping process, and improve product quality. For instance, machine learning algorithms can learn from past production data to adjust the vacuum level and capping pressure for different types of products, ensuring the best possible seal.

Sustainable Manufacturing

As the focus on sustainability grows, smart automatic glass bottle vacuum capping machines will play a role in reducing energy consumption and waste. They can be designed to use energy – efficient components and optimize the use of materials. For example, by accurately controlling the vacuum level, less energy is wasted in the vacuuming process. Additionally, the ability to reject defective products early in the process reduces material waste.

In conclusion, automatic glass bottle vacuum capping machines are leading the way in smart manufacturing. Their integration of advanced technologies such as automation, sensors, data analytics, and the potential for future IoT, AI, and sustainability features make them an essential part of the modern industrial ecosystem. These machines not only improve production efficiency and product quality but also contribute to a more sustainable and connected manufacturing future.