Table of Contents

Benefits of Using a Fully Automatic Sealing Machine for Meat Canned Tinplate Cans

Meat canned tinplate cans are a popular packaging choice for various types of meat products, including canned meats, sausages, and pâtés. These cans are durable, convenient, and provide a long shelf life for the products inside. However, sealing these cans can be a time-consuming and labor-intensive process, especially when done manually. This is where a fully automatic sealing machine can make a significant difference.

One of the key benefits of using a fully automatic sealing machine for meat canned tinplate cans is efficiency. These machines are designed to seal cans quickly and accurately, significantly reducing the time and labor required for the sealing process. With a fully automatic sealing machine, you can seal a large number of cans in a fraction of the time it would take to do so manually, allowing you to increase your production output and meet customer demand more effectively.

In addition to efficiency, fully automatic sealing machines also offer consistency in sealing quality. These machines are equipped with advanced technology that ensures a tight and secure seal on every can, reducing the risk of leaks or contamination. This is particularly important when packaging meat products, as a faulty seal can compromise the safety and quality of the product. By using a fully automatic sealing machine, you can have peace of mind knowing that each can is sealed to the highest standards.

Another benefit of using a fully automatic sealing machine for meat canned tinplate cans is cost savings. While the initial investment in a sealing machine may seem significant, the long-term savings can be substantial. By automating the sealing process, you can reduce the need for manual labor, saving on labor costs and increasing overall efficiency. Additionally, the consistent sealing quality provided by a fully automatic machine can help reduce product waste and minimize the risk of costly recalls due to faulty seals.

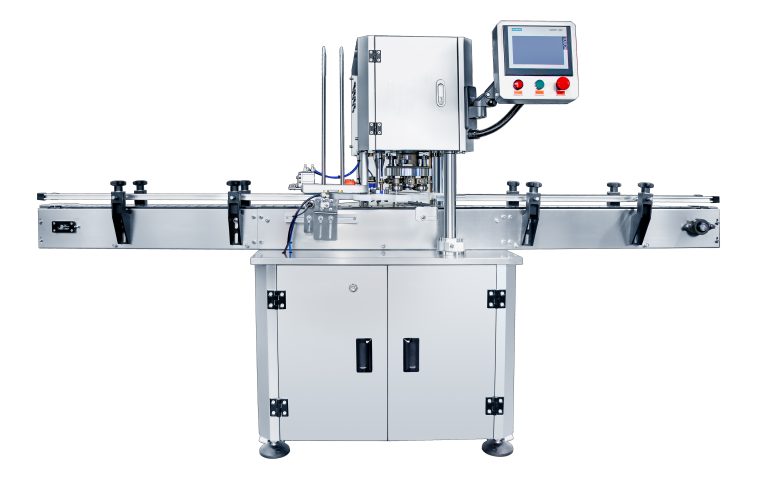

Furthermore, fully automatic sealing machines are designed for ease of use and maintenance. These machines are equipped with user-friendly interfaces and controls, making them easy to operate even for those with limited experience. Additionally, many sealing machines are designed for easy cleaning and maintenance, helping to prolong the lifespan of the machine and ensure optimal performance over time.

Overall, the benefits of using a fully automatic sealing machine for meat canned tinplate cans are clear. From increased efficiency and consistency in sealing quality to cost savings and ease of use, these machines offer a range of advantages for meat packaging operations. Whether you are a small artisanal producer or a large-scale manufacturer, investing in a fully automatic sealing machine can help streamline your production process and improve the overall quality of your products.

How to Choose the Right Fully Automatic Sealing Machine for Meat Canned Tinplate Cans

When it comes to sealing machines for meat canned tinplate cans, choosing the right fully automatic option is crucial for ensuring efficiency and product quality. With the wide range of options available on the market, it can be overwhelming to determine which machine is best suited for your specific needs. In this article, we will discuss key factors to consider when selecting a fully automatic sealing machine for meat canned tinplate cans.

First and foremost, it is important to consider the size and capacity of the machine. The size of the machine should be able to accommodate the volume of cans you need to seal on a daily basis. Additionally, the capacity of the machine should align with your production goals to ensure smooth operations. It is recommended to choose a machine with a slightly higher capacity than your current needs to account for potential growth in the future.

Another important factor to consider is the sealing mechanism of the machine. Fully automatic sealing machines for meat canned tinplate cans typically use either vacuum sealing or gas flushing techniques. Vacuum sealing removes air from the can before sealing, while gas flushing replaces the air with a protective gas such as nitrogen. Both techniques help to extend the shelf life of the product by preventing oxidation and microbial growth. Consider the specific requirements of your product when choosing between these sealing mechanisms.

In addition to the sealing mechanism, it is essential to consider the sealing quality of the machine. Look for a fully automatic sealing machine that can consistently produce airtight seals to prevent leakage and contamination. The machine should also be able to adjust the sealing pressure and temperature to accommodate different types of cans and products. Conducting tests with sample cans before making a purchase can help ensure that the machine meets your quality standards.

Furthermore, the ease of operation and maintenance of the machine should also be taken into account. A fully automatic sealing machine that is user-friendly and easy to clean will help streamline production processes and reduce downtime. Look for machines with intuitive controls and minimal maintenance requirements to maximize efficiency and productivity.

Lastly, consider the reputation and reliability of the manufacturer when choosing a fully automatic sealing machine for meat canned tinplate cans. Opt for a reputable manufacturer with a track record of producing high-quality machines and providing excellent customer support. Reading reviews and testimonials from other customers can also help gauge the reliability of the machine and the manufacturer.

In conclusion, selecting the right fully automatic sealing machine for meat canned tinplate cans requires careful consideration of factors such as size, capacity, sealing mechanism, sealing quality, ease of operation, maintenance, and manufacturer reputation. By taking these factors into account, you can choose a machine that meets your production needs and ensures the quality and safety of your products.