In the world of product packaging, ensuring the cleanliness and integrity of your products is of utmost importance. Dust and contaminants can compromise the quality of goods, especially in industries such as food, pharmaceuticals, and electronics. This is where dustproof plastic cover press capping machines come in as invaluable assets, working diligently to keep your products spotless.

Table of Contents

The Battle Against Dust in Packaging

Dust is a persistent problem in packaging environments. It can be carried in through the air, generated from the production process itself, or introduced during handling. In food production, dust can carry bacteria and other harmful microorganisms that can spoil the product and pose a health risk to consumers. Pharmaceutical products are equally vulnerable, as even a tiny particle of dust can contaminate a batch of medicine, rendering it ineffective or even dangerous.

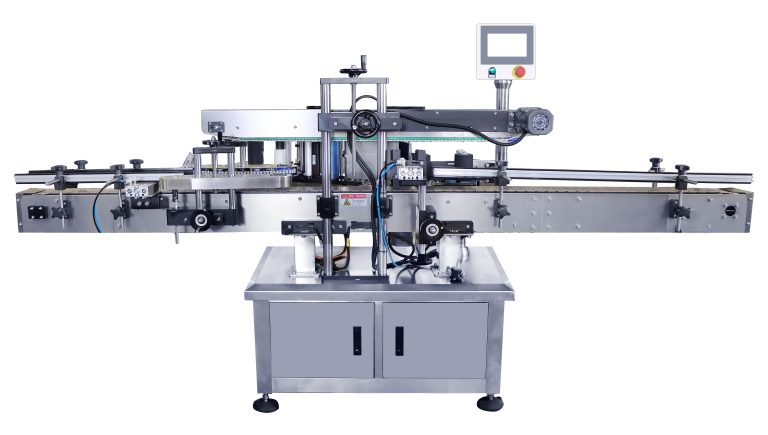

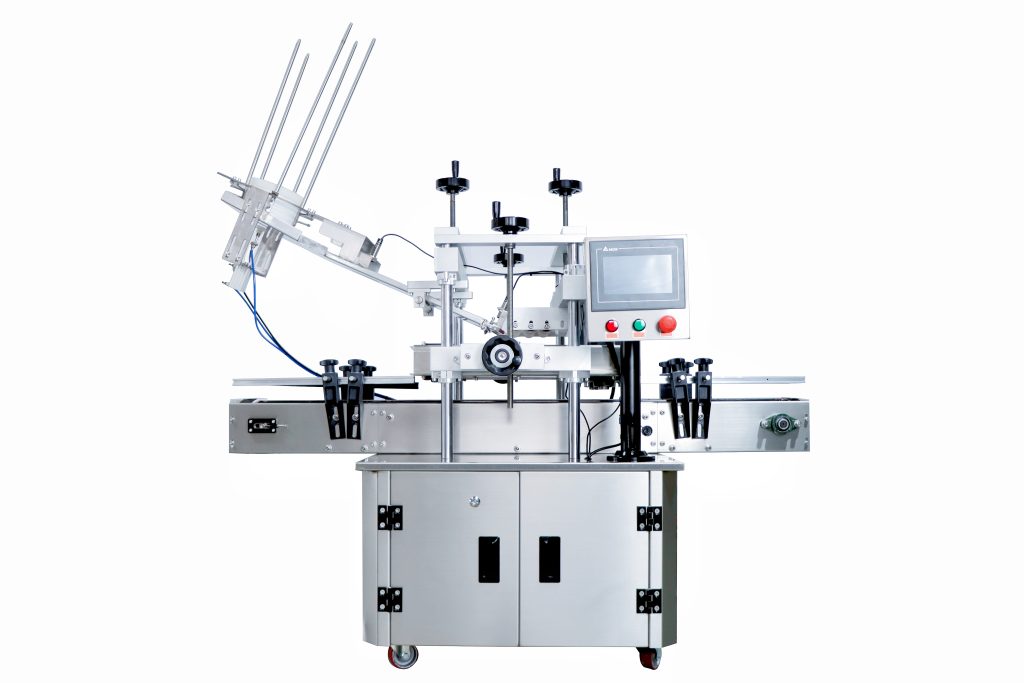

Traditional capping methods often leave products exposed to dust during the capping process. Manual capping is slow and inconsistent, and standard capping machines may not have the necessary features to prevent dust from settling on the product or inside the package. Dustproof plastic cover press capping machines, however, offer a comprehensive solution to this problem.

The Dustproof Barrier: Plastic Covers

The most prominent feature of these machines is their plastic covers. These covers are designed to create a sealed environment around the capping area, acting as a physical barrier against dust. The plastic used is carefully selected for its durability and dust – resistant properties.

In a food processing plant, for example, the dustproof plastic cover press capping machine’s cover prevents airborne dust from landing on the open containers before they are capped. This is crucial for products like powdered beverages or dry snacks, where even a small amount of dust can affect the taste and quality.

Precision Capping to Minimize Exposure

Dustproof plastic cover press capping machines are engineered to perform precise capping operations. They use advanced technology to accurately position the caps on the containers and apply the right amount of pressure for a secure fit. This precision is essential not only for a tight seal but also for minimizing the time the product is exposed to the environment.

In the electronics industry, where components are extremely sensitive to dust, the machine’s quick and accurate capping process ensures that the products are protected as soon as possible. Whether it’s a small circuit board in a plastic casing or a delicate electronic device in a box, the dustproof capping machine reduces the risk of dust contamination during the crucial capping stage.

Self – Cleaning and Maintenance Features

Many dustproof plastic cover press capping machines are equipped with self – cleaning and maintenance features. These features help to keep the machine itself free from dust and debris, which in turn helps to maintain a clean capping environment.

Some machines have built – in air filters that constantly remove dust from the air inside the capping area. Others have easy – to – clean surfaces and components that can be quickly wiped down or disassembled for thorough cleaning. This proactive approach to cleanliness ensures that the machine continues to operate at its best and keeps your products spotless.

Compatibility with Different Packaging Materials

These machines are designed to be versatile and can work with a wide range of packaging materials. Whether it’s plastic bottles, glass jars, or metal cans, the dustproof plastic cover press capping machine can adapt to different shapes and sizes.

In the cosmetic industry, where products come in various packaging formats, from small lip balm tubes to large lotion bottles, the machine can provide a dust – free capping solution for all. This compatibility allows businesses to use a single machine for multiple product lines, streamlining the packaging process and reducing the risk of cross – contamination.

Quality Assurance and Compliance

Using a dustproof plastic cover press capping machine is not only about keeping products clean but also about meeting quality assurance and regulatory requirements. In industries like food and pharmaceuticals, strict regulations govern the cleanliness and safety of products.

By using a dustproof capping machine, businesses can demonstrate their commitment to quality and compliance. The machine’s ability to prevent dust contamination helps to ensure that products meet the necessary standards, reducing the risk of product recalls and legal issues.

In conclusion, dustproof plastic cover press capping machines are essential tools for businesses that want to keep their products spotless. Their dustproof barriers, precision capping, self – cleaning features, compatibility with different packaging materials, and contribution to quality assurance make them a valuable investment in the packaging process. With these machines, businesses can protect their products from dust and contaminants, ensuring that they reach consumers in the best possible condition.