Table of Contents

Benefits of Using High Speed Plastic Container Twist Off Capping Machine with Cap Feeder

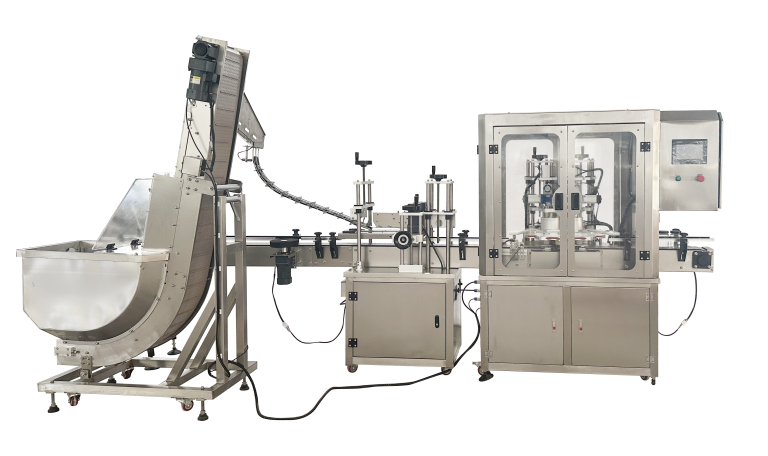

In the world of manufacturing, efficiency and speed are key factors in ensuring a successful production process. One area where these factors are particularly important is in the capping of plastic containers. Traditional capping methods can be time-consuming and labor-intensive, leading to bottlenecks in the production line. However, with the advent of high-speed plastic container twist-off capping machines with cap feeders, manufacturers can now enjoy a range of benefits that can significantly improve their production processes.

One of the primary benefits of using a high-speed plastic container twist-off capping machine with a cap feeder is the increase in production speed. These machines are designed to cap containers at a much faster rate than manual capping methods, allowing manufacturers to meet high production demands without sacrificing quality. This increased speed can help reduce production time and costs, ultimately leading to higher profits for the manufacturer.

In addition to increased production speed, high-speed plastic container twist-off capping machines with cap feeders also offer improved accuracy and consistency in capping. These machines are equipped with advanced technology that ensures each container is capped precisely and securely, reducing the risk of leaks or spills. This level of accuracy is crucial in industries where product quality and safety are paramount, such as in the food and pharmaceutical industries.

Furthermore, high-speed plastic container twist-off capping machines with cap feeders are designed to be user-friendly and easy to operate. This means that manufacturers can quickly train their staff to use these machines, reducing the need for specialized skills or extensive training. This ease of use can help streamline the production process and minimize downtime, ultimately leading to increased efficiency and productivity.

Another key benefit of using a high-speed plastic container twist-off capping machine with a cap feeder is the reduction in labor costs. By automating the capping process, manufacturers can significantly reduce the number of workers needed to cap containers manually. This can lead to substantial savings in labor costs, allowing manufacturers to allocate resources to other areas of their business.

Additionally, high-speed plastic container twist-off capping machines with cap feeders are designed to be versatile and adaptable to a wide range of container sizes and shapes. This flexibility allows manufacturers to use these machines for a variety of products, without the need for costly retooling or adjustments. This versatility can help manufacturers stay competitive in a rapidly changing market, where product diversity and customization are key factors in attracting customers.

In conclusion, the benefits of using a high-speed plastic container twist-off capping machine with a cap feeder are numerous and significant. From increased production speed and accuracy to reduced labor costs and improved versatility, these machines offer a range of advantages that can help manufacturers streamline their production processes and improve their bottom line. By investing in these advanced capping machines, manufacturers can stay ahead of the competition and meet the demands of a fast-paced manufacturing environment.

How to Choose the Right High Speed Plastic Container Twist Off Capping Machine with Cap Feeder for Your Business

In the world of manufacturing, efficiency and speed are key factors in ensuring a successful operation. When it comes to packaging products in plastic containers, having the right capping machine can make all the difference. One popular option for high-speed capping is the twist-off capping machine with a cap feeder. This machine is designed to quickly and accurately apply caps to plastic containers, making it an essential piece of equipment for businesses looking to streamline their packaging process.

When choosing a high-speed plastic container twist-off capping machine with a cap feeder for your business, there are several factors to consider. First and foremost, you’ll want to assess the speed and capacity of the machine. High-speed capping machines are capable of capping hundreds of containers per minute, making them ideal for businesses with large production volumes. Additionally, you’ll want to consider the size and shape of the containers you’ll be capping, as well as the type of caps you’ll be using. Make sure the machine you choose is compatible with your specific packaging needs.

Another important factor to consider when choosing a capping machine is the level of automation it offers. Some machines are fully automated, meaning they require minimal human intervention to operate. These machines are ideal for businesses looking to maximize efficiency and reduce labor costs. However, if you prefer more control over the capping process, you may opt for a semi-automated machine that requires some manual input.

In addition to speed, capacity, and automation, you’ll also want to consider the overall reliability and durability of the capping machine. Look for a machine that is built to last and can withstand the rigors of continuous use. It’s also a good idea to choose a machine from a reputable manufacturer with a track record of producing high-quality equipment.

One of the key features of a twist-off capping machine with a cap feeder is its ability to handle a wide range of cap sizes and styles. This versatility is essential for businesses that package products in various types of containers. Make sure the machine you choose can accommodate the caps you’ll be using, whether they are screw caps, snap caps, or flip-top caps.

When it comes to maintenance and servicing, choose a capping machine that is easy to clean and maintain. Regular maintenance is essential for keeping the machine running smoothly and preventing breakdowns. Look for a machine that comes with clear instructions for maintenance and troubleshooting, as well as easy access to replacement parts.

In conclusion, choosing the right high-speed plastic container twist-off capping machine with a cap feeder for your business is a crucial decision that can have a significant impact on your packaging process. Consider factors such as speed, capacity, automation, reliability, versatility, and maintenance when making your decision. By investing in a high-quality capping machine that meets your specific needs, you can streamline your packaging process and improve overall efficiency in your operation.