Table of Contents

Benefits of Using an Automatic Vacuum Nitrogen Sealing Machine for Milk Powder

Milk powder is a popular dairy product that is used in a variety of food and beverage applications. It is known for its long shelf life and convenience, making it a staple in many households. However, in order to maintain its freshness and quality, proper packaging is essential. One of the most effective ways to package milk powder is through vacuum nitrogen sealing.

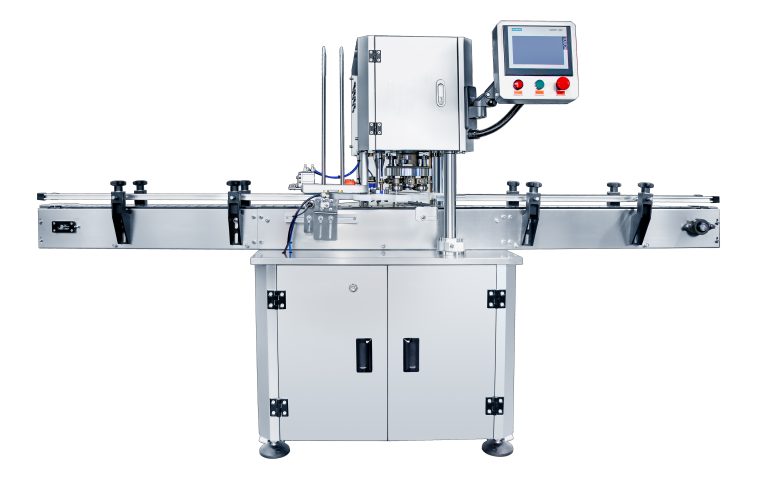

An automatic vacuum nitrogen sealing machine is a valuable tool for businesses that produce and package milk powder. This machine is designed to remove air from the packaging and replace it with nitrogen gas, which helps to preserve the freshness and quality of the product. There are several benefits to using an automatic vacuum nitrogen sealing machine for milk powder.

First and foremost, this machine helps to extend the shelf life of milk powder. By removing oxygen from the packaging, the risk of oxidation and spoilage is greatly reduced. Oxygen is a major contributor to the degradation of food products, so by eliminating it from the packaging, the milk powder can stay fresh for a longer period of time. This is especially important for businesses that need to store large quantities of milk powder for extended periods.

In addition to extending the shelf life of milk powder, an automatic vacuum nitrogen sealing machine also helps to maintain the quality of the product. Oxygen can cause milk powder to lose its flavor, color, and nutritional value over time. By sealing the packaging with nitrogen gas, the milk powder is protected from these harmful effects, ensuring that it retains its original taste and nutritional content.

Another benefit of using an automatic vacuum nitrogen sealing machine for milk powder is that it helps to prevent moisture from entering the packaging. Moisture can lead to the growth of bacteria and mold, which can spoil the milk powder and make it unsafe for consumption. By creating a vacuum seal with nitrogen gas, the machine effectively blocks out moisture, keeping the milk powder dry and free from contaminants.

Furthermore, an automatic vacuum nitrogen sealing machine is a cost-effective solution for businesses that package milk powder. By extending the shelf life of the product and reducing the risk of spoilage, businesses can minimize waste and save money on replacing expired or damaged inventory. Additionally, the machine is easy to operate and requires minimal maintenance, making it a practical investment for businesses of all sizes.

Overall, an automatic vacuum nitrogen sealing machine is a valuable asset for businesses that produce and package milk powder. By extending the shelf life, maintaining quality, preventing moisture, and reducing costs, this machine offers a range of benefits that can help businesses improve their operations and deliver high-quality products to consumers. Whether you are a small-scale producer or a large manufacturer, investing in an automatic vacuum nitrogen sealing machine can help you enhance the quality and longevity of your milk powder products.

How to Choose the Right Automatic Vacuum Nitrogen Sealing Machine for Milk Powder Packaging

When it comes to packaging milk powder, ensuring its freshness and quality is crucial. One way to achieve this is by using an automatic vacuum nitrogen sealing machine. This type of machine helps to remove oxygen from the packaging, which can extend the shelf life of the milk powder and prevent it from spoiling. However, with so many options available on the market, it can be overwhelming to choose the right automatic vacuum nitrogen sealing machine for your specific needs.

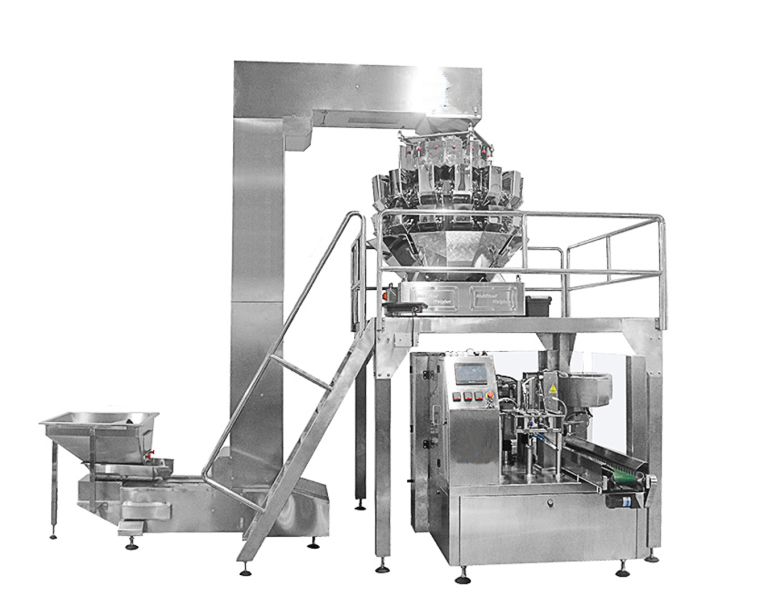

One of the first things to consider when selecting a machine is the size and capacity. Depending on the volume of milk powder you need to package, you will want to choose a machine that can handle the workload efficiently. Some machines are designed for small-scale production, while others are better suited for larger operations. It is important to assess your production needs and choose a machine that can keep up with demand.

Another important factor to consider is the level of automation. Some machines are fully automatic, meaning they require minimal human intervention to operate. These machines are ideal for high-volume production and can help streamline the packaging process. On the other hand, semi-automatic machines may require more manual labor but can be more cost-effective for smaller operations. Consider your budget and production requirements when deciding on the level of automation that is right for you.

In addition to size and automation, it is important to consider the sealing technology used in the machine. Vacuum nitrogen sealing machines use a combination of vacuum and nitrogen gas to remove oxygen from the packaging and create a tight seal. Some machines may use different sealing techniques, such as heat sealing or ultrasonic sealing. It is important to choose a machine that uses a sealing technology that is suitable for milk powder packaging to ensure the freshness and quality of the product.

When selecting an automatic vacuum nitrogen sealing machine, it is also important to consider the overall build quality and durability of the machine. Look for machines that are made from high-quality materials and are built to last. A durable machine will be able to withstand the rigors of daily use and provide reliable performance over time. Additionally, consider the reputation of the manufacturer and read reviews from other users to ensure you are investing in a quality machine.

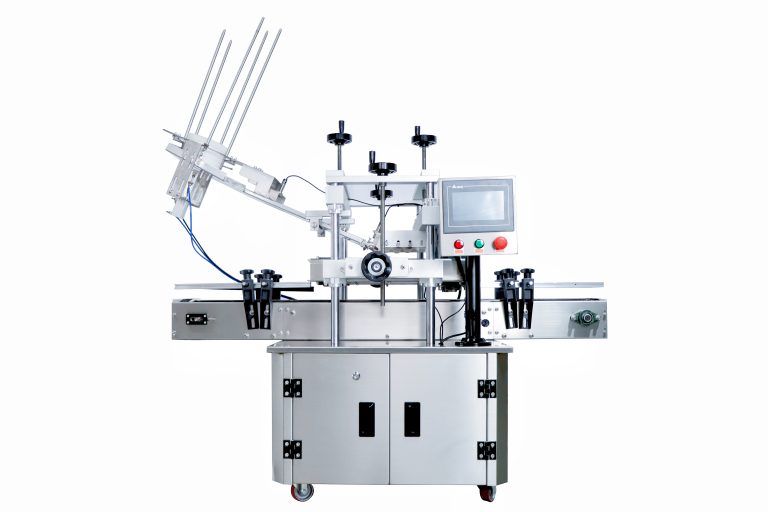

Finally, consider the additional features and capabilities of the machine. Some machines may offer customizable settings for sealing time and pressure, allowing you to tailor the packaging process to your specific needs. Others may have built-in sensors and alarms to alert you to any issues during the sealing process. Consider what features are important to you and choose a machine that offers the functionality you need.

In conclusion, choosing the right automatic vacuum nitrogen sealing machine for milk powder packaging is essential to ensuring the freshness and quality of the product. Consider factors such as size, automation, sealing technology, build quality, and additional features when making your decision. By selecting a machine that meets your production needs and quality standards, you can ensure that your milk powder remains fresh and delicious for your customers.

Maintenance Tips for Ensuring Optimal Performance of an Automatic Vacuum Nitrogen Sealing Machine for Milk Powder

An automatic vacuum nitrogen sealing machine is an essential piece of equipment for packaging milk powder. This machine ensures that the milk powder remains fresh and free from contaminants by creating a vacuum-sealed environment and filling the package with nitrogen gas. To ensure optimal performance and longevity of the machine, proper maintenance is crucial.

One of the most important maintenance tasks for an automatic vacuum nitrogen sealing machine is regular cleaning. Over time, dust, debris, and residue from the milk powder can build up inside the machine, leading to decreased efficiency and potential contamination of the product. It is recommended to clean the machine after each use, paying special attention to the sealing and vacuuming components.

In addition to regular cleaning, it is important to inspect the machine for any signs of wear and tear. Check the seals, gaskets, and other components for cracks, tears, or other damage that could compromise the sealing process. Replace any worn parts immediately to prevent leaks and ensure a tight seal.

Another important maintenance task is lubricating the moving parts of the machine. Proper lubrication helps reduce friction and wear on the components, extending the life of the machine. Use a food-grade lubricant recommended by the manufacturer and follow their guidelines for application.

Regular calibration of the machine is also essential for optimal performance. Over time, the settings of the machine may drift, leading to inaccuracies in the vacuum and nitrogen levels. Calibrate the machine according to the manufacturer’s instructions to ensure that it is operating at peak efficiency.

In addition to these maintenance tasks, it is important to follow proper operating procedures when using the automatic vacuum nitrogen sealing machine. Avoid overloading the machine or running it for extended periods without a break, as this can lead to overheating and premature wear. Follow the recommended operating parameters for sealing time, vacuum level, and nitrogen gas flow to ensure consistent and reliable results.

Proper storage of the machine when not in use is also important for maintaining its performance. Store the machine in a clean, dry environment away from direct sunlight and extreme temperatures. Cover the machine to protect it from dust and debris when not in use.

By following these maintenance tips, you can ensure that your automatic vacuum nitrogen sealing machine for milk powder remains in top condition and continues to provide reliable performance. Regular cleaning, inspection, lubrication, calibration, and proper operation are key to maximizing the lifespan of the machine and ensuring the quality and safety of your packaged milk powder. Invest the time and effort in maintaining your machine, and you will be rewarded with consistent, high-quality packaging for your product.