Table of Contents

Benefits of Using an Automatic Can Closing Machine

Automatic can closing machines are a valuable tool for businesses looking to streamline their packaging processes. These machines offer a range of benefits that can help improve efficiency, reduce labor costs, and ensure consistent quality in the packaging of canned goods. In this article, we will explore some of the key benefits of using an automatic can closing machine.

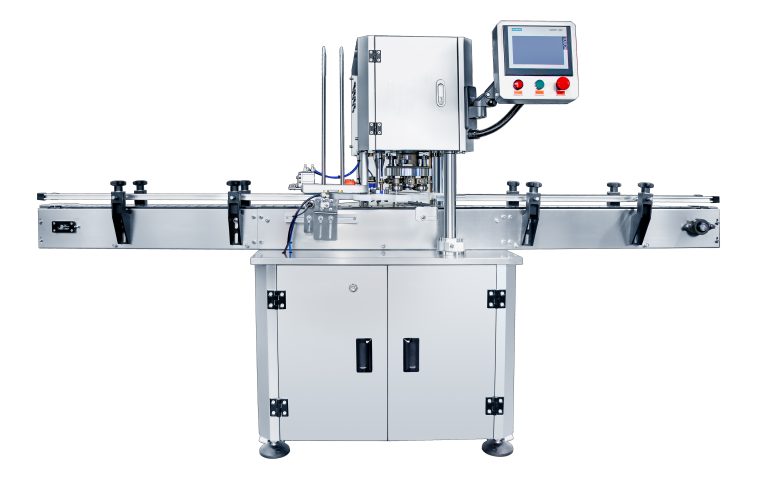

One of the primary benefits of using an automatic can closing machine is the increase in efficiency that it provides. These machines are designed to close cans quickly and accurately, allowing businesses to package their products at a much faster rate than would be possible with manual labor. This can help businesses meet production deadlines and keep up with customer demand, ultimately leading to increased profitability.

In addition to improving efficiency, automatic can closing machines can also help reduce labor costs. By automating the can closing process, businesses can eliminate the need for manual laborers to perform this task, freeing up employees to focus on other aspects of production. This can result in significant cost savings over time, as businesses no longer need to pay for labor to perform repetitive and time-consuming tasks.

Another key benefit of using an automatic can closing machine is the consistent quality that it provides. These machines are designed to close cans with precision and accuracy, ensuring that each can is sealed properly and securely. This can help businesses maintain a high level of quality control in their packaging processes, reducing the risk of product spoilage or contamination. Consistent quality can also help businesses build a strong reputation for reliability and consistency among customers.

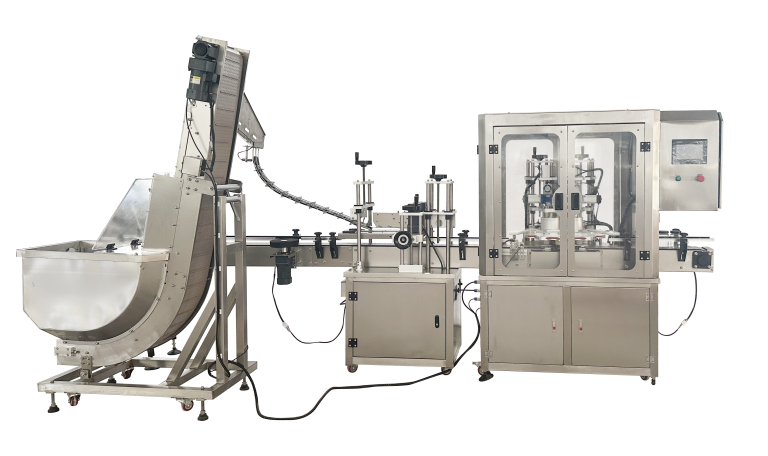

Automatic can closing machines are also highly versatile, capable of handling a wide range of can sizes and types. This flexibility allows businesses to package a variety of products using the same machine, reducing the need for multiple machines or manual adjustments. This can help businesses save time and money on equipment costs, as well as reduce the risk of errors or inconsistencies in packaging.

In addition to these benefits, automatic can closing machines are also easy to operate and maintain. Most machines are equipped with user-friendly interfaces and controls, making them simple to set up and operate. Maintenance requirements are typically minimal, with routine cleaning and lubrication being the primary tasks needed to keep the machine running smoothly. This can help businesses save time and money on maintenance costs, as well as reduce downtime due to equipment malfunctions.

Overall, automatic can closing machines offer a range of benefits that can help businesses improve efficiency, reduce labor costs, and ensure consistent quality in their packaging processes. By investing in an automatic can closing machine, businesses can streamline their operations, increase productivity, and ultimately achieve greater success in the competitive marketplace.

How to Choose the Right Automatic Can Closing Machine for Your Needs

Automatic can closing machines are a valuable asset for businesses looking to streamline their packaging processes. These machines are designed to efficiently seal cans with lids, ensuring that products are securely packaged and ready for distribution. If you are considering investing in an automatic can closing machine for your business, it is important to choose the right machine that meets your specific needs. In this article, we will provide a beginner’s guide to selecting the right automatic can closing machine for your business.

When choosing an automatic can closing machine, the first step is to consider the size and type of cans that you will be sealing. Automatic can closing machines come in a variety of sizes and configurations to accommodate different can sizes and shapes. It is important to choose a machine that is compatible with the cans you will be using to ensure a proper seal.

Another important factor to consider when selecting an automatic can closing machine is the speed and efficiency of the machine. Different machines have varying capacities and speeds, so it is important to choose a machine that can keep up with your production needs. Consider the volume of cans that you will be sealing on a daily basis and choose a machine that can handle that capacity.

In addition to size and speed, it is also important to consider the level of automation that you require. Some automatic can closing machines are fully automated, while others require manual intervention at certain points in the sealing process. Consider your production process and determine the level of automation that will best suit your needs.

When selecting an automatic can closing machine, it is also important to consider the quality and reliability of the machine. Look for machines from reputable manufacturers that have a track record of producing high-quality equipment. A reliable machine will ensure consistent and accurate sealing, reducing the risk of product spoilage or damage.

Cost is another important factor to consider when choosing an automatic can closing machine. Automatic can closing machines can vary significantly in price, so it is important to set a budget and stick to it. Consider the long-term cost of ownership, including maintenance and repair costs, when making your decision.

Finally, it is important to consider the support and service options available for the automatic can closing machine. Look for a manufacturer that offers comprehensive support and training to ensure that your machine operates efficiently and effectively. Consider the availability of spare parts and technical support to minimize downtime and keep your production running smoothly.

In conclusion, choosing the right automatic can closing machine for your business is a critical decision that requires careful consideration of several factors. By considering the size and type of cans you will be sealing, the speed and efficiency of the machine, the level of automation required, the quality and reliability of the machine, the cost, and the support and service options available, you can select a machine that meets your specific needs and helps streamline your packaging process. With the right automatic can closing machine, you can improve efficiency, reduce waste, and ensure that your products are securely packaged and ready for distribution.

Maintenance Tips for Keeping Your Automatic Can Closing Machine Running Smoothly

Automatic can closing machines are essential equipment for businesses in the food and beverage industry. These machines help streamline the packaging process by sealing cans quickly and efficiently. However, like any piece of machinery, automatic can closing machines require regular maintenance to ensure they continue to operate smoothly. In this article, we will provide some maintenance tips to help you keep your automatic can closing machine running smoothly.

One of the most important maintenance tasks for your automatic can closing machine is regular cleaning. Over time, dust, debris, and other contaminants can build up on the machine’s components, leading to decreased performance and potential breakdowns. To prevent this, it is essential to clean your machine regularly. This can be done by wiping down the machine with a damp cloth and using a mild detergent to remove any stubborn residue. Additionally, you should regularly inspect the machine for any signs of wear or damage and address any issues promptly.

In addition to cleaning, it is also important to lubricate your automatic can closing machine regularly. Proper lubrication helps reduce friction between moving parts, which can help prevent premature wear and tear. Before lubricating your machine, be sure to consult the manufacturer’s guidelines for the type of lubricant to use and the recommended schedule for application. Over-lubrication can be just as harmful as under-lubrication, so be sure to follow the manufacturer’s recommendations closely.

Another important maintenance task for your automatic can closing machine is inspecting and replacing worn or damaged parts. Over time, the components of your machine can become worn or damaged, leading to decreased performance and potential breakdowns. Regularly inspecting your machine for signs of wear or damage can help you identify and address issues before they become more serious. Additionally, it is important to replace any worn or damaged parts promptly to prevent further damage to the machine.

Regularly calibrating your automatic can closing machine is also essential for maintaining its performance. Calibration ensures that the machine is operating at the correct settings, which can help prevent issues such as misaligned seals or improperly closed cans. Be sure to follow the manufacturer’s guidelines for calibrating your machine and perform this task regularly to ensure optimal performance.

Finally, it is important to train your staff on proper machine operation and maintenance. Proper training can help prevent issues such as operator error or improper maintenance, which can lead to decreased performance and potential breakdowns. Be sure to provide your staff with the necessary training and resources to operate and maintain the machine effectively.

In conclusion, regular maintenance is essential for keeping your automatic can closing machine running smoothly. By following these maintenance tips, you can help prevent issues such as decreased performance and potential breakdowns, ensuring that your machine continues to operate efficiently. Remember to clean, lubricate, inspect, calibrate, and train your staff regularly to keep your automatic can closing machine in top condition.