Table of Contents

Benefits of Using a 6 Heads Piston Filling Machine for Meat Sauce Production

In the food industry, efficiency and accuracy are crucial factors in ensuring the quality and consistency of products. When it comes to producing meat sauce, having the right equipment can make a significant difference in the production process. One such piece of equipment that can greatly benefit meat sauce production is a 6 heads piston filling machine.

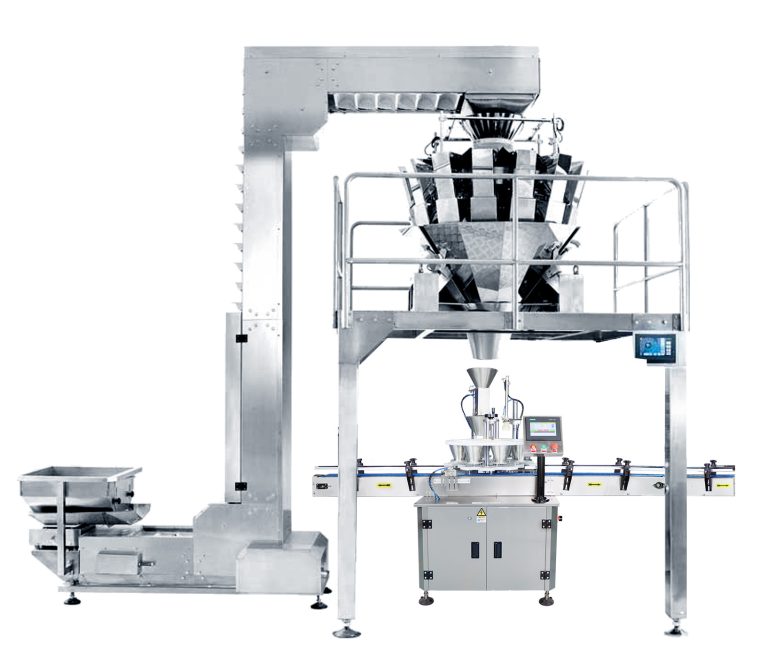

A 6 heads piston filling machine is a versatile and efficient piece of equipment that is specifically designed for filling viscous products like meat sauce. This machine is equipped with six individual pistons that can fill multiple containers simultaneously, increasing the production output and reducing the time and labor required for filling.

One of the key benefits of using a 6 heads piston filling machine for meat sauce production is its high level of accuracy. The machine is programmed to dispense a precise amount of sauce into each container, ensuring that every product meets the desired weight and consistency. This level of accuracy is essential for maintaining the quality and consistency of the meat sauce, which is crucial for customer satisfaction and brand reputation.

Another advantage of using a 6 heads piston filling machine is its speed and efficiency. With six pistons working simultaneously, the machine can fill a large number of containers in a short amount of time, significantly increasing the production output. This not only helps to meet the demands of a high-volume production environment but also reduces the overall production time, allowing for faster turnaround times and increased efficiency.

In addition to accuracy and efficiency, a 6 heads piston filling machine also offers versatility in terms of container size and shape. The machine can be easily adjusted to accommodate different container sizes, from small jars to large bottles, making it suitable for a variety of packaging requirements. This flexibility allows for greater customization and adaptability in the production process, ensuring that the meat sauce can be packaged in the most suitable and appealing way for consumers.

Furthermore, a 6 heads piston filling machine is designed for easy operation and maintenance. The machine is equipped with user-friendly controls and interfaces, making it simple for operators to set up and adjust the filling parameters. Additionally, the machine is constructed with high-quality materials and components that are durable and easy to clean, reducing the risk of contamination and ensuring the longevity of the equipment.

Overall, the benefits of using a 6 heads piston filling machine for meat sauce production are clear. From its high level of accuracy and efficiency to its versatility and ease of operation, this machine offers a range of advantages that can greatly improve the production process. By investing in a 6 heads piston filling machine, food manufacturers can enhance their production capabilities, increase their output, and ultimately deliver high-quality meat sauce products to their customers.

Step-by-Step Guide on How to Operate a 6 Heads Piston Filling Machine for Meat Sauce

A 6 heads piston filling machine is a versatile piece of equipment that can greatly increase efficiency in the production of meat sauce. This machine is designed to accurately fill containers with a predetermined amount of sauce, ensuring consistency in product quality. In this article, we will provide a step-by-step guide on how to operate a 6 heads piston filling machine for meat sauce.

First and foremost, it is important to ensure that the machine is properly set up and calibrated before use. This includes adjusting the fill volume, speed, and other settings to meet the specific requirements of the meat sauce being produced. It is also crucial to clean and sanitize the machine thoroughly to prevent contamination and ensure food safety.

Once the machine is set up and ready to go, the next step is to prepare the meat sauce for filling. This may involve heating the sauce to a certain temperature, mixing it thoroughly to ensure consistency, and transferring it to a holding tank or reservoir that can be connected to the filling machine.

With the meat sauce prepared and the machine ready to go, it is time to start the filling process. The containers to be filled should be placed on the conveyor belt or other feeding mechanism of the machine, and the filling heads should be positioned above the containers.

As the containers move along the conveyor belt, the filling heads will lower into the containers and dispense the predetermined amount of meat sauce. The pistons in the filling heads will push the sauce into the containers, ensuring accurate and consistent filling.

It is important to monitor the filling process closely to ensure that the containers are being filled properly and that there are no leaks or spills. Adjustments may need to be made to the machine settings or the filling heads to optimize the filling process and prevent any issues.

Once the containers are filled, they can be moved along the conveyor belt to the next stage of the production process, such as capping or labeling. It is important to handle the filled containers carefully to prevent spills or contamination.

After the filling process is complete, it is important to clean and sanitize the machine thoroughly to prevent any residue or contamination from affecting future batches of meat sauce. This may involve disassembling the filling heads and other components of the machine for a more thorough cleaning.

In conclusion, a 6 heads piston filling machine is a valuable tool for efficiently filling containers with meat sauce. By following the steps outlined in this guide, operators can ensure that the machine is set up properly, the meat sauce is prepared correctly, and the filling process is carried out accurately and consistently. With proper maintenance and care, a 6 heads piston filling machine can help streamline production and improve the quality of meat sauce products.