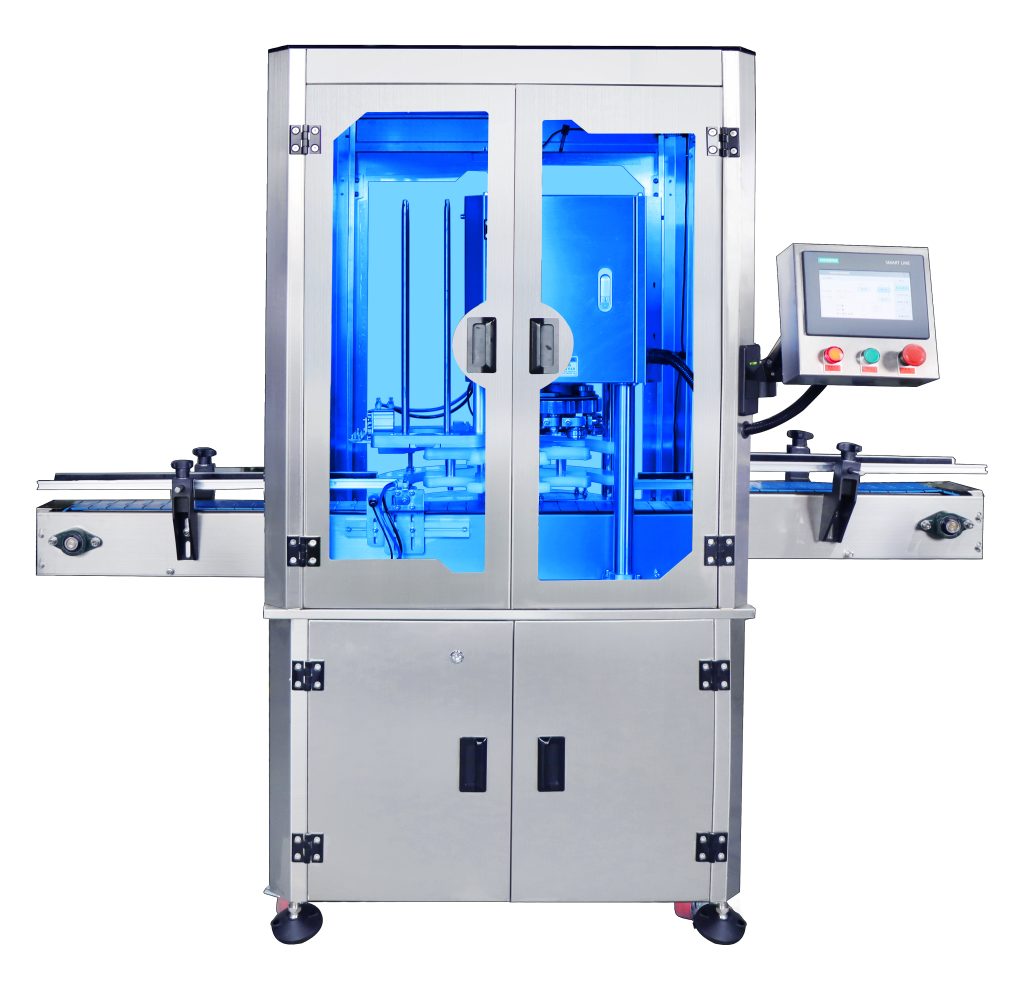

Automatic Round Can Sealing Machines, Can Closing Machine, Can Crimping Machine, Can Seamer

The machine is applicable for sealing of various tin cans,aluminum cans,paper cans and all kinds of round cans.It is simple in operation and it is anideal packing equipment of food,beverage,pharmaceutical and the other industry.

Main Features:

1.Whole machine servo control makes the equipment run safer, more stable and smarter. The turntable only runs when there is a can, speed can be adjusted separately; when there is can stuck, the turntable will automatically stop. After one button reset, the error can bbe released and machine restart to run; When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial equipment damage and safety accidents caused bby incorrect operation of the equipment.

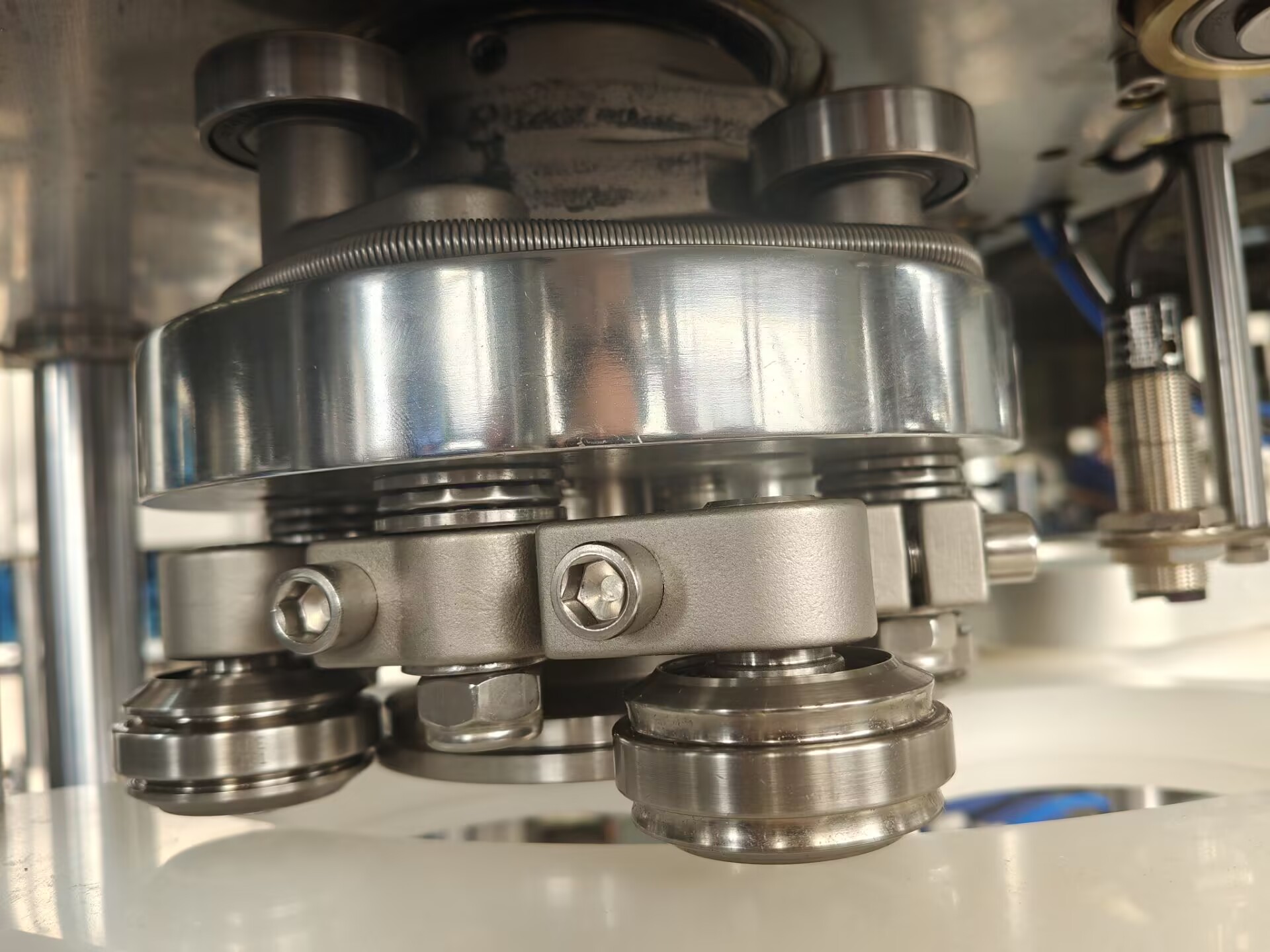

2. A total of 4 seaming rollers are completed at the same time to ensure high sealing performance.

3. The can body does not rotate during the sealing process, which is safer and is especially suitable for fragile and liquid products.

4. The sealing speed can reach up to 50 cans per minute, high production efficiency.

5.The whole machine has a transparent blue acrylic cover, multiple protection, more beautiful and safe.

6. Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the ideal packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

Main parameters:

1.Sealing head qty:1 piece

2.Seaming roller:4pcs(2pcs first operation and 2pcs second operation)

3.Sealing speed:25-50pcs/min

4.Can height:27-106mm

5.Can diameter:65mm

6.operating temperature:0~45℃,operating humidity:35~85%

7.Working power supply: three phrase AC220V-240 50/60Hz

8.Total power:2100w

9.Weight:330kg

10.L185*W84*H165cm