Table of Contents

Benefits of Using Plastic Cover Soft Cover Dust Cap Capping Machine

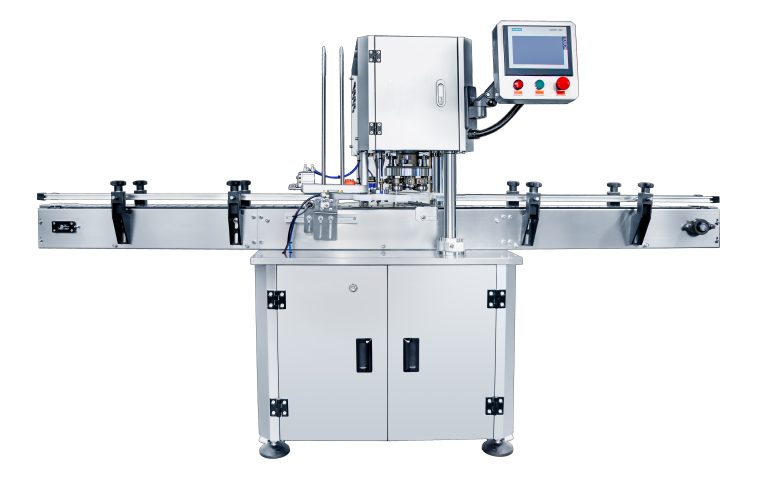

Plastic cover soft cover dust cap capping machines are essential tools in the packaging industry. These machines are designed to efficiently and accurately apply plastic covers or soft covers to products, ensuring that they are protected from dust, dirt, and other contaminants. There are many benefits to using a plastic cover soft cover dust cap capping machine, including increased productivity, improved product quality, and reduced labor costs.

One of the primary benefits of using a plastic cover soft cover dust cap capping machine is increased productivity. These machines are capable of capping hundreds of products per minute, far surpassing the speed at which manual capping can be done. This increased efficiency allows companies to package their products more quickly, leading to faster turnaround times and increased output. Additionally, the consistent and precise application of caps by these machines ensures that products are sealed properly every time, reducing the risk of leaks or contamination.

Another benefit of using a plastic cover soft cover dust cap capping machine is improved product quality. These machines are designed to apply caps with a high level of accuracy and precision, ensuring that each product is sealed securely and neatly. This not only enhances the overall appearance of the product but also helps to maintain its freshness and integrity. By using a capping machine, companies can ensure that their products are consistently sealed to the highest standards, leading to increased customer satisfaction and loyalty.

In addition to increased productivity and improved product quality, using a plastic cover soft cover dust cap capping machine can also help companies reduce labor costs. Manual capping can be a time-consuming and labor-intensive process, requiring workers to spend hours applying caps to products by hand. By automating this process with a capping machine, companies can significantly reduce the amount of labor required, freeing up employees to focus on other tasks. This not only saves time and money but also helps to improve overall efficiency and productivity within the company.

Overall, the benefits of using a plastic cover soft cover dust cap capping machine are clear. These machines offer increased productivity, improved product quality, and reduced labor costs, making them an essential tool for companies in the packaging industry. By investing in a capping machine, companies can streamline their packaging process, increase output, and ensure that their products are sealed to the highest standards. With these benefits in mind, it is clear that a plastic cover soft cover dust cap capping machine is a valuable asset for any company looking to improve their packaging operations.

How to Choose the Right Plastic Cover Soft Cover Dust Cap Capping Machine for Your Business

In today’s fast-paced world, businesses are constantly looking for ways to streamline their operations and increase efficiency. One way to achieve this is by investing in the right equipment, such as a plastic cover soft cover dust cap capping machine. These machines are designed to quickly and accurately apply caps to bottles, jars, and other containers, saving time and labor costs in the process.

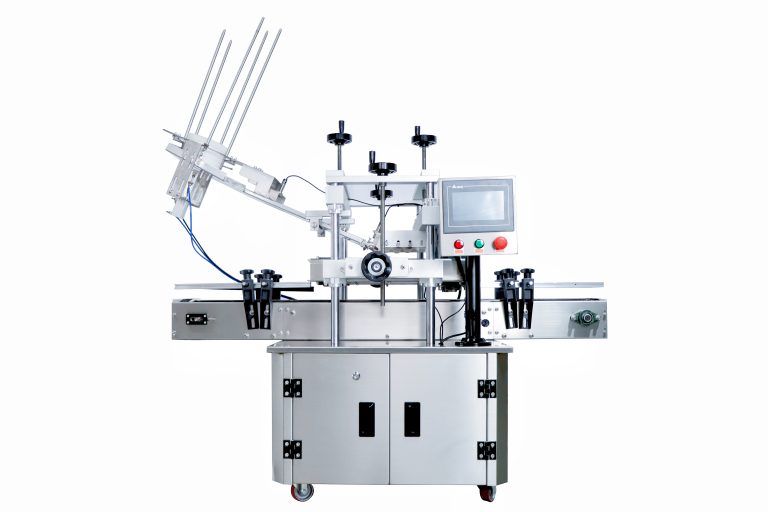

When it comes to choosing the right plastic cover soft cover dust cap capping machine for your business, there are several factors to consider. One of the most important things to think about is the size and type of containers you will be capping. Different machines are designed to handle different sizes and shapes of containers, so it’s essential to choose a machine that is compatible with your specific needs.

Another important consideration is the speed and efficiency of the machine. Some machines are capable of capping hundreds of containers per minute, while others may only be able to cap a few dozen. If you have a high-volume production line, you will want to invest in a machine that can keep up with your output requirements.

In addition to speed and compatibility, it’s also important to consider the quality and reliability of the machine. Look for a machine that is made from durable materials and is built to last. You don’t want to invest in a machine that will break down after a few months of use, as this can lead to costly downtime and repairs.

Cost is another important factor to consider when choosing a plastic cover soft cover dust cap capping machine. While it’s important to stay within your budget, it’s also essential to remember that quality is key. Investing in a high-quality machine may cost more upfront, but it will likely save you money in the long run by reducing maintenance and repair costs.

When researching different machines, be sure to read reviews and testimonials from other businesses that have used the machines. This can give you valuable insight into the performance and reliability of the machine, helping you make an informed decision.

Once you have chosen a plastic cover soft cover dust cap capping machine that meets your needs, it’s important to properly maintain and care for the machine to ensure optimal performance. Regular cleaning and maintenance can help extend the life of the machine and prevent breakdowns.

In conclusion, choosing the right plastic cover soft cover dust cap capping machine for your business is a crucial decision that can have a significant impact on your production line. By considering factors such as compatibility, speed, quality, and cost, you can make an informed decision that will benefit your business in the long run. Remember to research different machines, read reviews, and properly maintain your machine to ensure optimal performance and efficiency.