Inhoudsopgave

Advantages of Using Dulal Head Vacuum Capper Equipment for Glass Bottle Packaging

Glass bottles are a popular choice for packaging various products, such as beverages, sauces, and cosmetics. To ensure the safety and quality of the products inside these bottles, it is essential to seal them properly. One effective way to achieve a secure seal is by using a vacuum capper equipment, such as the Dulal Head Vacuum Capper.

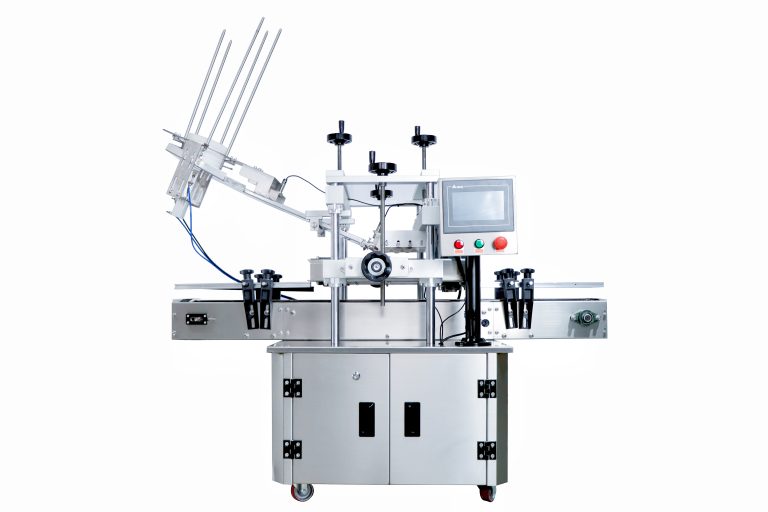

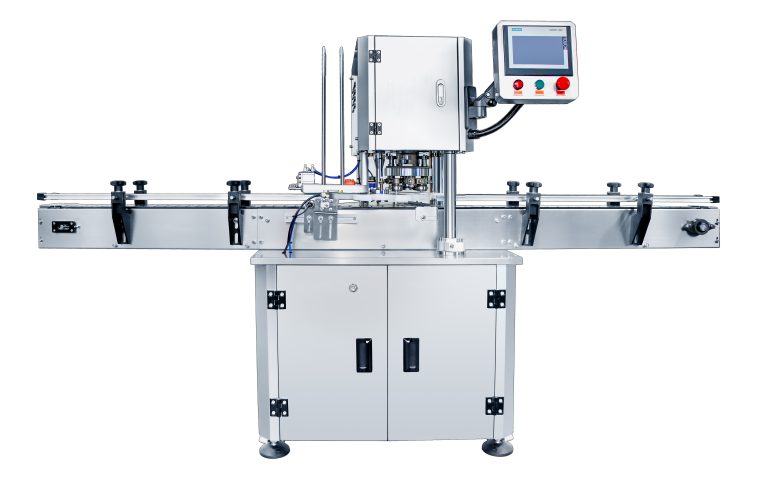

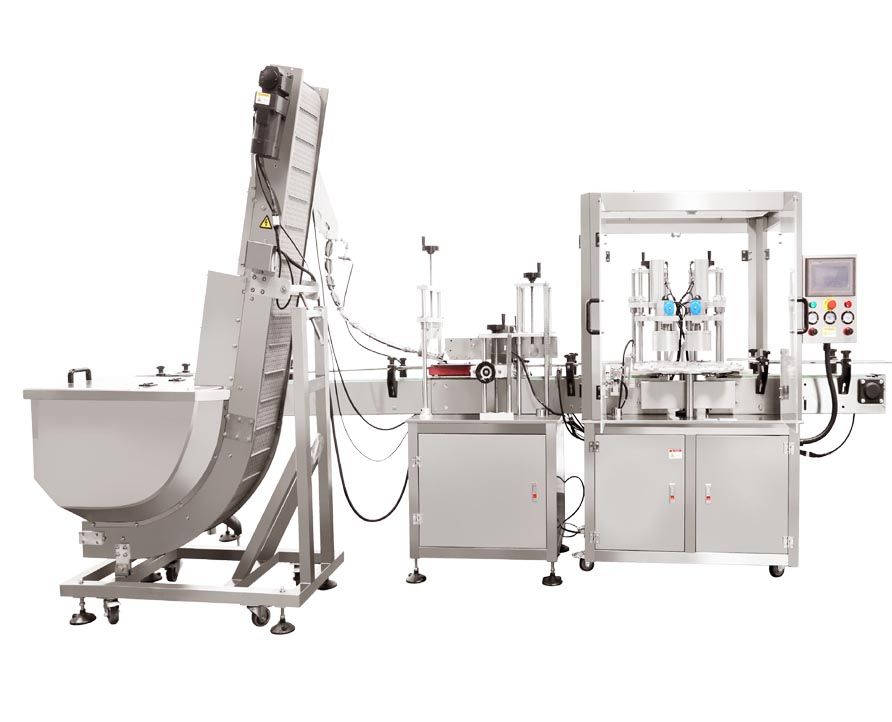

The Dulal Head Vacuum Capper is a state-of-the-art machine designed to cap glass bottles with precision and efficiency. This equipment is equipped with multiple capping heads, allowing it to cap multiple bottles simultaneously. This feature not only speeds up the packaging process but also ensures uniformity in the capping of each bottle.

One of the key advantages of using the Dulal Head Vacuum Capper is its ability to create a vacuum seal on the bottles. This vacuum seal helps to preserve the freshness and quality of the products inside the bottles by preventing air and contaminants from entering. As a result, the products have a longer shelf life and maintain their flavor and aroma for an extended period.

In addition to creating a vacuum seal, the Dulal Head Vacuum Capper also ensures a tight and secure cap on each bottle. This is crucial for preventing leaks and spills during storage and transportation. The equipment is designed to apply the right amount of pressure to the caps, ensuring a tight seal without damaging the bottles or the caps.

Furthermore, the Dulal Head Vacuum Capper is versatile and can be used for capping bottles of various shapes and sizes. Whether you are packaging small vials or large jars, this equipment can accommodate your needs. This versatility makes it a cost-effective solution for businesses that package products in different types of glass bottles.

Another advantage of using the Dulal Head Vacuum Capper is its user-friendly design. The equipment is easy to operate, with intuitive controls and settings that can be adjusted to suit your specific packaging requirements. This ease of use reduces the need for extensive training and allows operators to quickly set up and start using the machine.

Moreover, the Dulal Head Vacuum Capper is built to last, with a durable construction that can withstand the rigors of daily use in a production environment. This reliability ensures consistent performance and minimizes downtime, allowing businesses to meet their production targets efficiently.

In conclusion, the Dulal Head Vacuum Capper is a valuable piece of equipment for businesses that package products in glass bottles. Its ability to create a vacuum seal, ensure a tight cap, accommodate various bottle sizes, and user-friendly design make it a versatile and cost-effective solution for packaging needs. By investing in this equipment, businesses can improve the quality and safety of their products while increasing efficiency in their packaging processes.

Step-by-Step Guide on How to Properly Operate Dulal Head Vacuum Capper Equipment for Glass Bottle Sealing

Glass bottles are a popular choice for packaging various products, from beverages to cosmetics. To ensure the contents of these bottles remain fresh and sealed properly, it is essential to use the right equipment for sealing. One such equipment is the Dulal Head Vacuum Capper, which is specifically designed for sealing glass bottles. In this article, we will provide a step-by-step guide on how to properly operate the Dulal Head Vacuum Capper equipment for glass bottle sealing.

First and foremost, it is important to familiarize yourself with the Dulal Head Vacuum Capper equipment. This equipment consists of a vacuum chamber, a capping head, and a control panel. The vacuum chamber is where the bottle will be placed for sealing, while the capping head is responsible for applying the cap onto the bottle. The control panel allows you to adjust the settings of the equipment to suit your specific sealing requirements.

To begin the sealing process, start by placing the glass bottle into the vacuum chamber of the Dulal Head Vacuum Capper equipment. Make sure the bottle is positioned securely and upright to ensure a proper seal. Once the bottle is in place, close the vacuum chamber lid to create a vacuum seal around the bottle.

Next, adjust the settings on the control panel of the Dulal Head Vacuum Capper equipment. You can adjust the vacuum level, capping speed, and other parameters to suit the type of bottle and cap you are using. It is important to follow the manufacturer’s instructions for setting up the equipment to ensure a successful sealing process.

Once the settings are adjusted, press the start button on the control panel to begin the sealing process. The capping head will then lower onto the bottle and apply the cap with the desired amount of pressure. The vacuum chamber will also remove any excess air from the bottle to create a tight seal.

After the sealing process is complete, carefully remove the sealed bottle from the vacuum chamber of the Dulal Head Vacuum Capper equipment. Inspect the seal to ensure it is tight and secure. If there are any issues with the seal, you may need to adjust the settings on the control panel and repeat the sealing process.

In conclusion, the Dulal Head Vacuum Capper equipment is a valuable tool for sealing glass bottles effectively. By following the step-by-step guide outlined in this article, you can ensure that your glass bottles are properly sealed and the contents remain fresh. Remember to familiarize yourself with the equipment, adjust the settings accordingly, and carefully inspect the sealed bottles for a successful sealing process. With the right equipment and proper technique, you can confidently seal glass bottles with the Dulal Head Vacuum Capper equipment.