It seems we can’t find what you’re looking for. Perhaps searching can help.

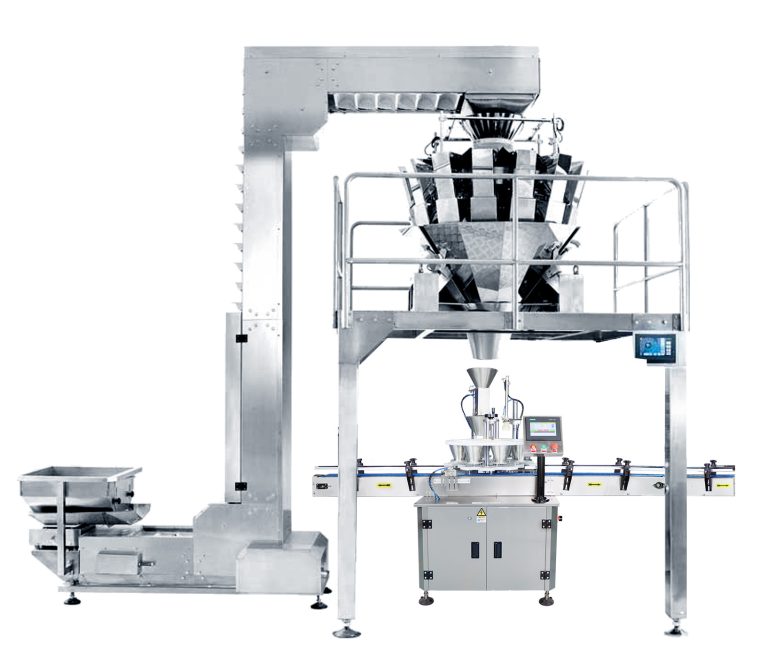

믹스너트 멀티헤드 칭량 충진: 포장 효율성 향상

더 믹스너트 멀티헤드 계량 충진 시스템 이러한 인기 간식을 포장하는 혁신적인 접근 방식입니다. 이 첨단 기술을 통해 믹스너트를 다양한 용기에 정확하고 빠르게 충전할 수 있습니다. 멀티 헤드 설계로 충전 공정이 빠르고 정확할 수 있습니다. 각 헤드가 동시에 작동하여 생산 속도가 크게 향상됩니다. 그 믹스너트 멀티헤드 계량 충진 시스템 필요한 믹스…