Table of Contents

Benefits of Using a Labeling Machine for Round Can Body Packaging

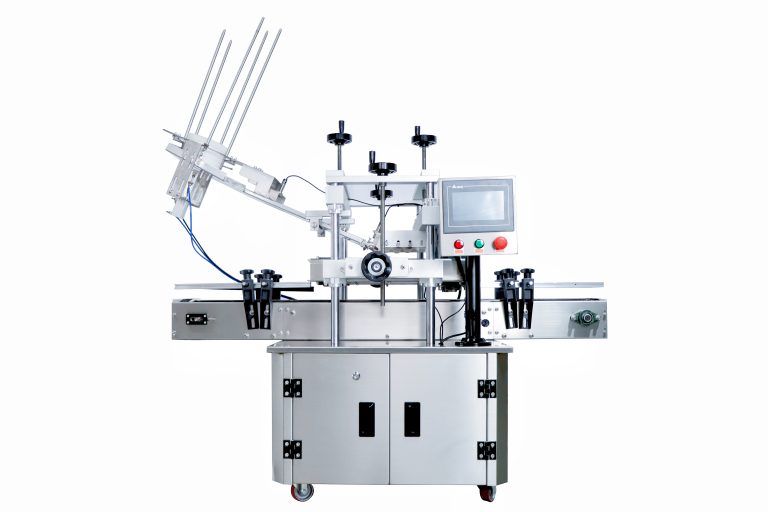

Labeling machines have become an essential tool in the packaging industry, offering numerous benefits for businesses looking to streamline their production processes. One particular type of labeling machine that has gained popularity is the labeling machine for round can bodies. These machines are specifically designed to apply labels to cylindrical containers, such as cans, bottles, and jars, with precision and efficiency.

One of the key benefits of using a labeling machine for round can bodies is the speed at which labels can be applied. Manual labeling can be a time-consuming and labor-intensive process, requiring workers to carefully align and apply each label by hand. In contrast, labeling machines are capable of applying labels to hundreds of cans per minute, significantly increasing production output and reducing labor costs.

In addition to speed, labeling machines for round can bodies also offer a high level of accuracy. These machines are equipped with advanced sensors and positioning systems that ensure labels are applied in the correct position and orientation on each can. This level of precision is crucial for maintaining product quality and consistency, especially in industries where branding and labeling play a key role in consumer perception.

Another benefit of using a labeling machine for round can bodies is the versatility they offer. These machines can accommodate a wide range of can sizes and shapes, making them suitable for packaging various products, from food and beverages to cosmetics and pharmaceuticals. Additionally, labeling machines can be easily adjusted to apply different types of labels, such as wrap-around labels, front and back labels, and tamper-evident labels, allowing businesses to meet the specific labeling requirements of their products.

Furthermore, labeling machines for round can bodies are designed to be user-friendly and easy to operate. Most modern labeling machines are equipped with intuitive touchscreen interfaces and programmable settings that allow operators to quickly set up and adjust the machine for different labeling tasks. This not only reduces the learning curve for operators but also minimizes the risk of human error during the labeling process.

In terms of cost savings, investing in a labeling machine for round can bodies can result in long-term benefits for businesses. By automating the labeling process, businesses can reduce the need for manual labor, which can lead to significant savings in labor costs over time. Additionally, labeling machines are designed to be durable and reliable, requiring minimal maintenance and repair, further reducing operational costs in the long run.

Overall, the benefits of using a labeling machine for round can bodies are clear. From increased production speed and accuracy to versatility and cost savings, these machines offer a range of advantages for businesses looking to improve their packaging processes. By investing in a labeling machine, businesses can streamline their production operations, enhance product quality, and ultimately, increase their competitiveness in the market.

How to Choose the Right Labeling Machine for Round Can Body Packaging

When it comes to packaging products in round cans, having the right labeling machine is essential to ensure efficiency and accuracy in the labeling process. Labeling machines are designed to apply labels to various types of packaging, including round can bodies. Choosing the right labeling machine for round can body packaging requires careful consideration of several factors to ensure that the machine meets your specific needs and requirements.

One of the first things to consider when choosing a labeling machine for round can body packaging is the type of labels you will be using. Different labeling machines are designed to work with specific types of labels, such as paper labels, plastic labels, or shrink sleeve labels. It is important to choose a labeling machine that is compatible with the type of labels you will be using to ensure that the labels are applied accurately and securely to the round can bodies.

Another important factor to consider when choosing a labeling machine for round can body packaging is the speed and efficiency of the machine. The speed at which the labeling machine can apply labels to round can bodies will impact the overall productivity of your packaging process. It is important to choose a labeling machine that can keep up with the production demands of your business to ensure that labels are applied quickly and accurately to each round can body.

In addition to speed and efficiency, it is also important to consider the accuracy of the labeling machine. Labels that are applied inaccurately can result in wasted materials and products, as well as potential issues with product identification and branding. Choosing a labeling machine that is designed to apply labels accurately to round can bodies will help to ensure that each label is applied correctly and consistently, resulting in a professional and polished finished product.

When choosing a labeling machine for round can body packaging, it is also important to consider the size and shape of the round can bodies that will be labeled. Some labeling machines are designed to work with specific sizes and shapes of packaging, so it is important to choose a machine that is compatible with the round can bodies you will be using. This will help to ensure that labels are applied accurately and securely to each round can body, regardless of its size or shape.

Finally, it is important to consider the overall cost of the labeling machine when choosing a machine for round can body packaging. Labeling machines can vary significantly in price, depending on their features, capabilities, and brand. It is important to choose a labeling machine that fits within your budget while still meeting your specific needs and requirements for labeling round can bodies.

In conclusion, choosing the right labeling machine for round can body packaging requires careful consideration of several factors, including the type of labels you will be using, the speed and efficiency of the machine, the accuracy of the machine, the size and shape of the round can bodies, and the overall cost of the machine. By taking these factors into account, you can choose a labeling machine that will help to streamline your packaging process and ensure that labels are applied accurately and securely to each round can body.