Table of Contents

Benefits of Implementing a Granular Quantitative Weighing and Filling Production Line

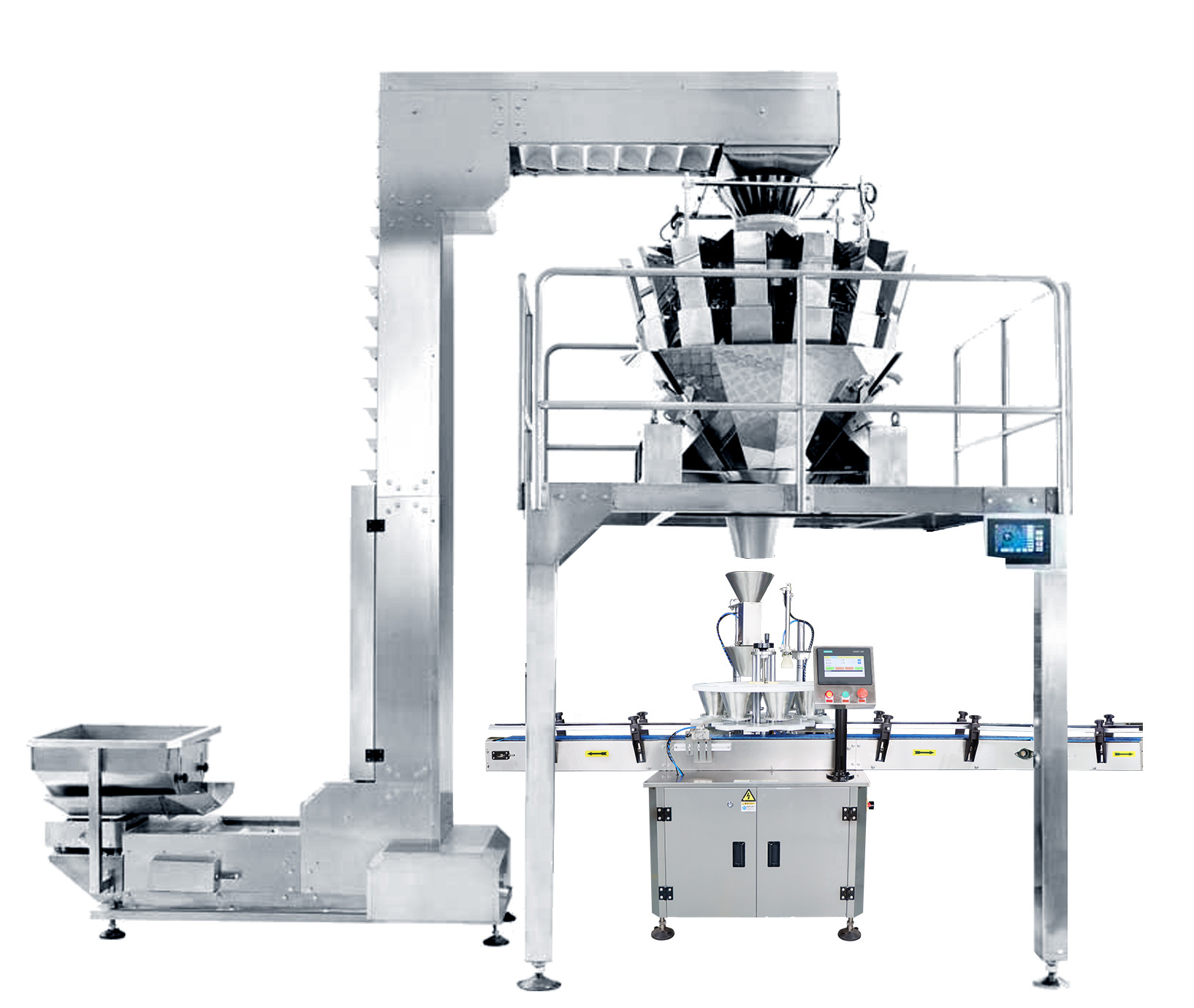

Granular products are a common commodity in various industries, from food and pharmaceuticals to chemicals and agriculture. When it comes to packaging these granular products, accuracy and efficiency are crucial. This is where a granular quantitative weighing and filling production line comes into play. This advanced technology offers numerous benefits for businesses looking to streamline their production processes and improve overall efficiency.

One of the key benefits of implementing a granular quantitative weighing and filling production line is the precision it offers. This technology allows for accurate measurement and filling of granular products, ensuring that each package contains the exact amount specified. This level of precision is essential for industries where consistency and quality control are paramount, such as the pharmaceutical and food industries.

In addition to precision, a granular quantitative weighing and filling production line also offers increased efficiency. By automating the weighing and filling process, businesses can significantly reduce the time and labor required to package granular products. This not only speeds up production but also helps to minimize the risk of human error, leading to a more reliable and consistent end product.

Furthermore, implementing a granular quantitative weighing and filling production line can help businesses save on costs in the long run. By reducing the need for manual labor and minimizing product waste through accurate measurements, businesses can improve their bottom line and increase profitability. Additionally, the efficiency of this technology allows for higher production volumes, enabling businesses to meet growing demand without sacrificing quality.

Another benefit of a granular quantitative weighing and filling production line is its versatility. This technology can be customized to accommodate a wide range of granular products, from powders and grains to pellets and seeds. This flexibility makes it an ideal solution for businesses with diverse product lines or those looking to expand into new markets.

Moreover, a granular quantitative weighing and filling production line can also help businesses meet regulatory requirements and industry standards. By ensuring accurate measurements and consistent packaging, businesses can avoid costly fines and penalties for non-compliance. This level of quality control is essential for industries where product safety and integrity are paramount.

Overall, the benefits of implementing a granular quantitative weighing and filling production line are clear. From precision and efficiency to cost savings and versatility, this technology offers numerous advantages for businesses looking to improve their packaging processes. By investing in this advanced technology, businesses can streamline their operations, increase productivity, and ultimately, enhance their competitive edge in the market.

How to Choose the Right Equipment for Your Granular Quantitative Weighing and Filling Production Line

When it comes to choosing the right equipment for your granular quantitative weighing and filling production line, there are several factors to consider. From the type of granular material you will be working with to the speed and accuracy requirements of your production process, selecting the right equipment is crucial to the success of your operation.

One of the first things to consider when choosing equipment for your production line is the type of granular material you will be working with. Different materials have different properties that can affect how they flow through the equipment and how accurately they can be weighed and filled. For example, fine powders may require different equipment than larger granules or irregularly shaped particles. It is important to choose equipment that is specifically designed to handle the type of material you will be working with to ensure accurate and consistent results.

Another important factor to consider when choosing equipment for your production line is the speed and accuracy requirements of your process. Some production lines may require high-speed filling and weighing capabilities to meet production quotas, while others may prioritize accuracy and precision over speed. It is important to carefully consider your specific production needs and choose equipment that can meet those requirements without sacrificing quality.

In addition to considering the type of material and speed requirements of your production line, it is also important to think about the overall efficiency and reliability of the equipment you choose. Look for equipment that is easy to operate and maintain, with a proven track record of reliability and performance. Investing in high-quality equipment may require a larger upfront investment, but it can ultimately save you time and money in the long run by reducing downtime and minimizing the risk of errors or malfunctions.

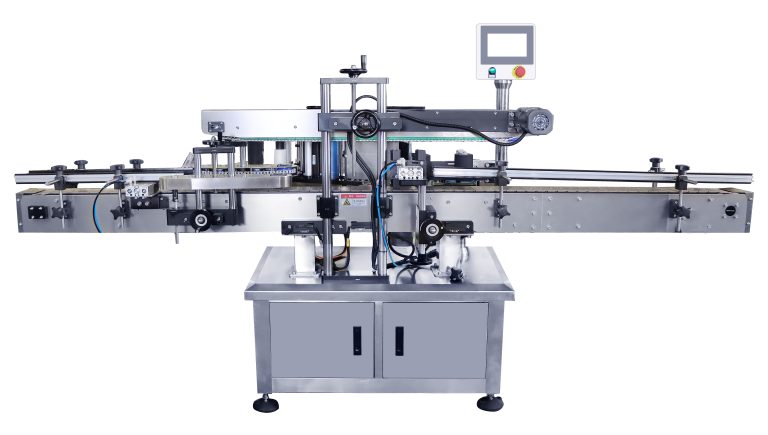

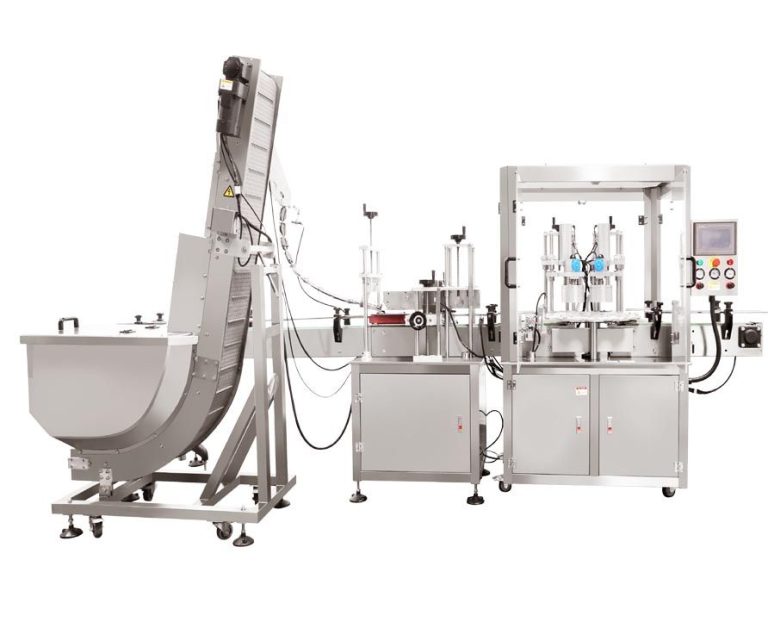

When selecting equipment for your granular quantitative weighing and filling production line, it is also important to consider the level of automation and integration you require. Some equipment may offer advanced automation features, such as programmable settings and data tracking capabilities, that can help streamline your production process and improve overall efficiency. Additionally, choosing equipment that can easily integrate with other systems in your production line, such as conveyors or packaging equipment, can help ensure a seamless and efficient workflow.

Ultimately, choosing the right equipment for your granular quantitative weighing and filling production line requires careful consideration of your specific production needs and requirements. By taking the time to research and evaluate different options, you can select equipment that is tailored to your operation and will help you achieve your production goals. Whether you prioritize speed, accuracy, efficiency, or automation, there is a wide range of equipment available to meet your needs and help you optimize your production process.

Tips for Optimizing Efficiency and Accuracy in Your Granular Quantitative Weighing and Filling Production Line

Granular quantitative weighing and filling production lines are essential for industries that require precise measurements and consistent filling of products. These production lines are commonly used in industries such as food processing, pharmaceuticals, and chemicals. Optimizing efficiency and accuracy in these production lines is crucial for ensuring product quality and reducing waste. Here are some tips to help you achieve optimal performance in your granular quantitative weighing and filling production line.

First and foremost, it is important to calibrate your weighing and filling equipment regularly. This ensures that the measurements are accurate and consistent, which is essential for maintaining product quality. Regular calibration also helps to identify any issues with the equipment early on, allowing for timely repairs and preventing costly downtime.

In addition to calibration, it is important to properly maintain your weighing and filling equipment. This includes cleaning and inspecting the equipment regularly to ensure that it is in good working condition. Proper maintenance not only extends the lifespan of the equipment but also helps to prevent inaccuracies in measurements and filling.

Another tip for optimizing efficiency and accuracy in your production line is to use high-quality granular materials. Using low-quality or inconsistent materials can lead to variations in weight and filling, which can affect product quality. By using high-quality materials, you can ensure that your products meet the required specifications and standards.

Furthermore, it is important to train your staff on the proper use of the weighing and filling equipment. Proper training ensures that your staff understands how to operate the equipment correctly and can identify any issues that may arise during production. Training also helps to prevent errors and reduce the risk of accidents in the workplace.

Implementing automation in your production line can also help to optimize efficiency and accuracy. Automated weighing and filling systems can perform tasks quickly and accurately, reducing the risk of human error. Automation also allows for real-time monitoring of production processes, enabling you to make adjustments as needed to maintain optimal performance.

Additionally, it is important to track and analyze data from your production line to identify areas for improvement. By monitoring key performance indicators such as fill accuracy, throughput, and downtime, you can identify bottlenecks and inefficiencies in your production line. This data-driven approach allows you to make informed decisions to optimize your production processes.

Lastly, it is important to continuously review and update your production line to incorporate the latest technologies and best practices. By staying up-to-date with industry trends and advancements, you can ensure that your production line remains competitive and efficient. Regularly evaluating and improving your production line helps to maintain product quality, reduce waste, and increase overall efficiency.

In conclusion, optimizing efficiency and accuracy in your granular quantitative weighing and filling production line is essential for ensuring product quality and reducing waste. By following these tips, you can achieve optimal performance in your production line and maintain a competitive edge in the market. Remember to calibrate and maintain your equipment, use high-quality materials, train your staff, implement automation, track and analyze data, and continuously review and update your production line to achieve success.