It seems we can’t find what you’re looking for. Perhaps searching can help.

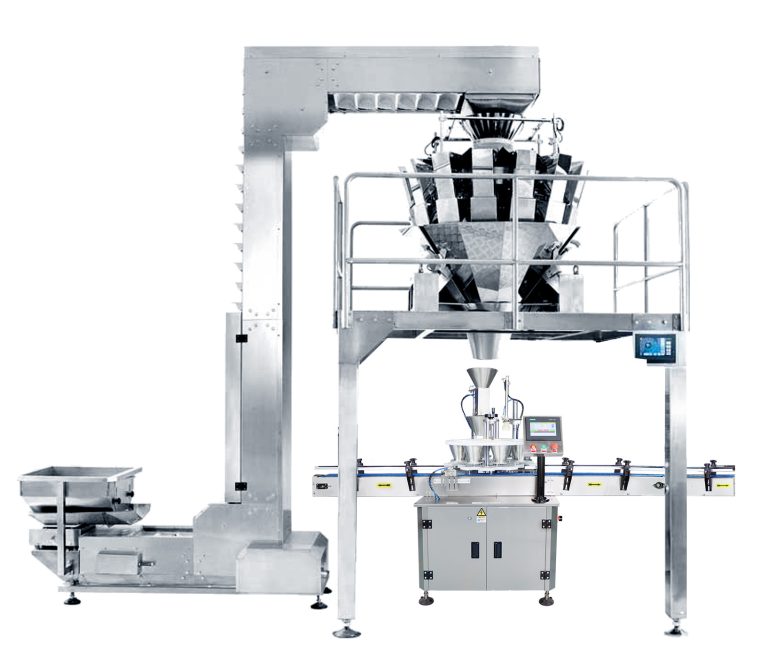

“How Automatic Powder Auger Fillers Save Time and Reduce Waste”

Automatic powder auger fillers offer significant time-saving and waste reduction benefits in various industrial processes. Firstly, they operate at high speeds, filling multiple containers in a short period. This rapid filling rate drastically reduces the overall production time compared to manual or slower filling methods. The precise control and measurement…