It seems we can’t find what you’re looking for. Perhaps searching can help.

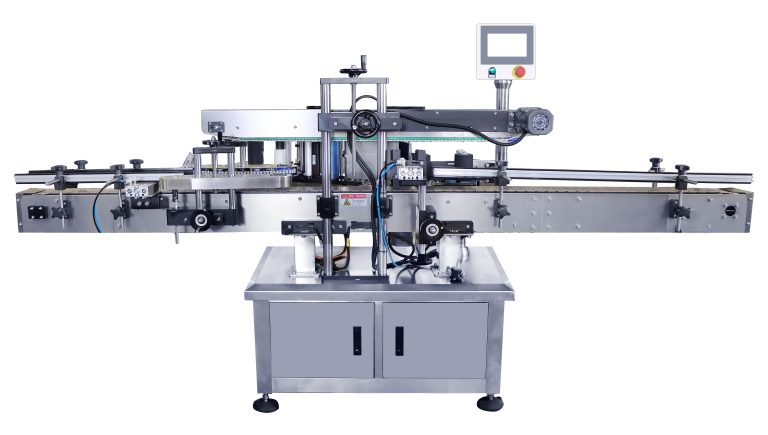

Automatic vinegar sauce liquid filler

Benefits of Using Automatic Vinegar Sauce Liquid Filler in Food Production In the food production industry, efficiency and accuracy are key factors in ensuring a successful operation. One piece of equipment that can greatly improve these aspects is an automatic vinegar sauce liquid filler. This machine is designed to accurately…