It seems we can’t find what you’re looking for. Perhaps searching can help.

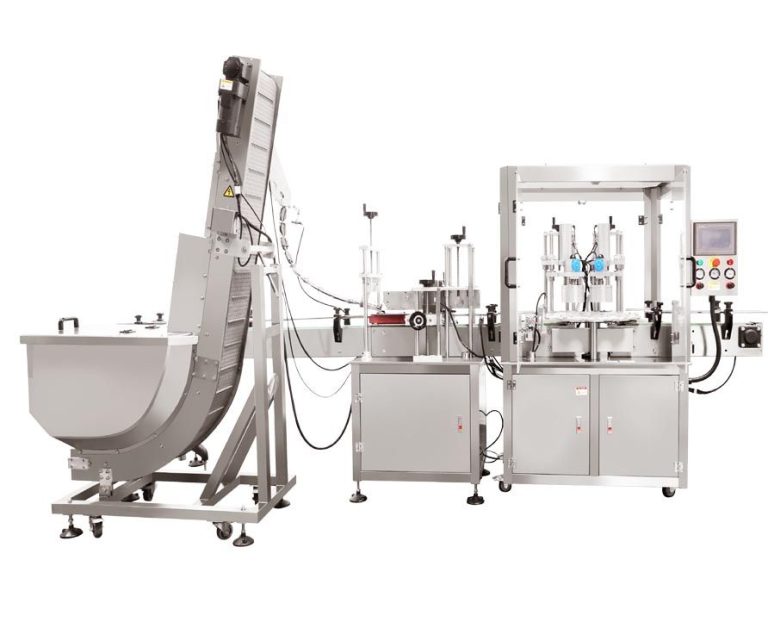

The Automatic Bottle Liquid Filling Machine: Filling with Efficiency and Accuracy

The Automatic Bottle Liquid Filling Machine is a revolutionary device in the packaging industry. This machine offers seamless and precise filling of liquids into bottles. It ensures that each bottle is filled to the exact level, minimizing waste and maintaining product consistency. One of the key advantages is its high-speed…