Increased Efficiency and Productivity

In today’s fast-paced manufacturing industry, efficiency and productivity are key factors in determining the success of a business. One way to improve efficiency and productivity in the production process is by investing in a can closing machine. These machines offer a wide range of advantages that can help streamline operations and increase output.

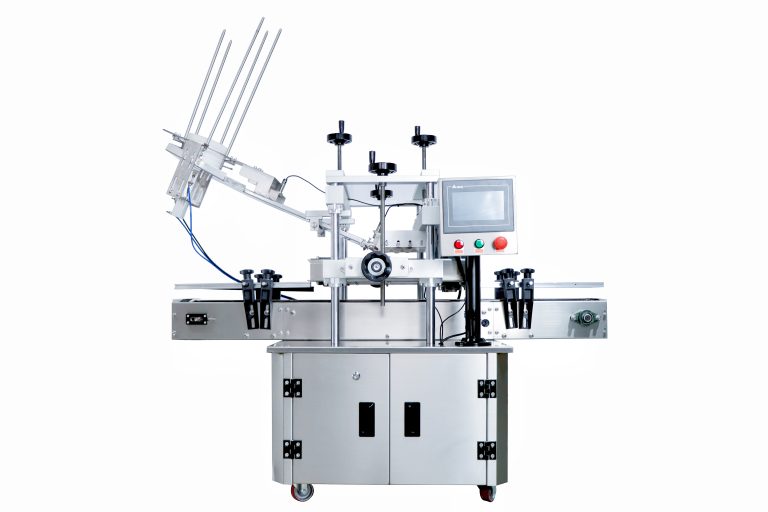

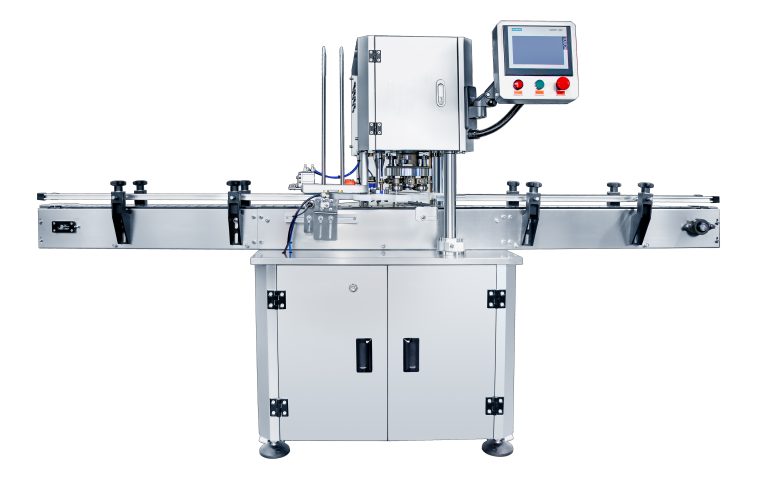

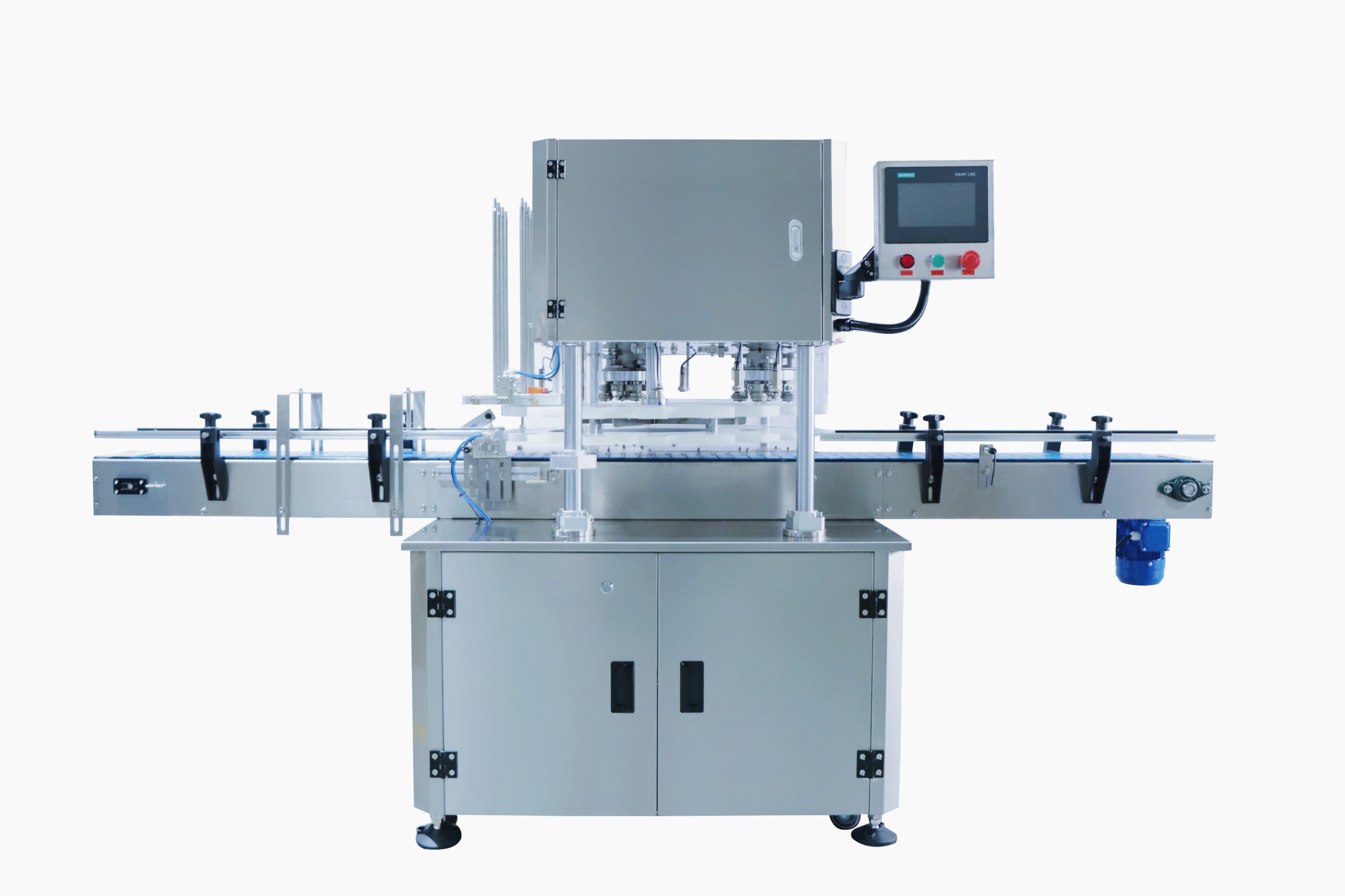

One of the main advantages of a can closing machine is its ability to automate the can closing process. Manual can closing can be a time-consuming and labor-intensive task, requiring workers to carefully seal each can by hand. This can lead to inconsistencies in the sealing process, resulting in leaks or spoilage. By using a can closing machine, companies can ensure that each can is sealed properly and efficiently, reducing the risk of product contamination and waste.

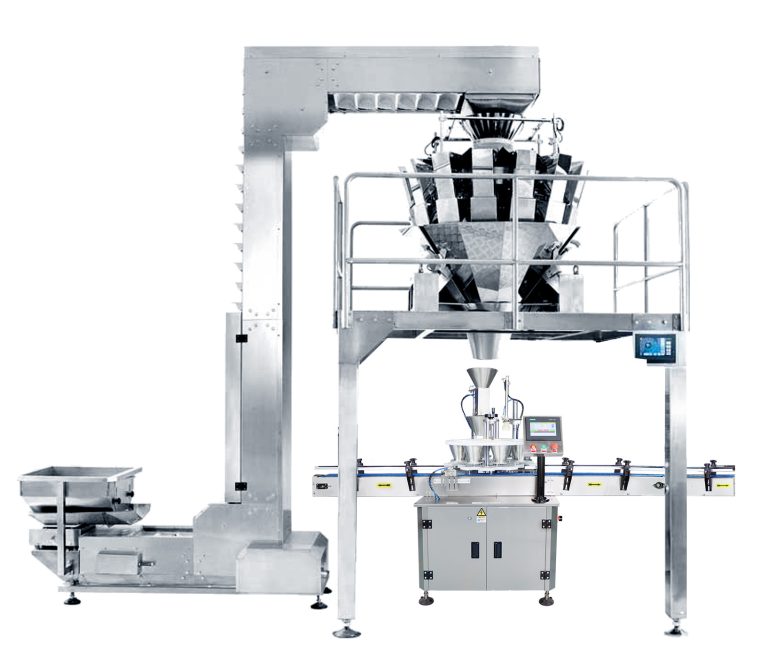

Additionally, can closing machines are designed to handle a high volume of cans in a short amount of time. This means that companies can increase their production output without having to hire additional workers or invest in expensive equipment. By automating the can closing process, businesses can save time and money, allowing them to focus on other aspects of their operations.

Another advantage of can closing machines is their versatility. These machines are capable of sealing a wide range of can sizes and materials, making them suitable for a variety of products. Whether companies are packaging food, beverages, or other goods, a can closing machine can be customized to meet their specific needs. This flexibility allows businesses to adapt to changing market demands and expand their product offerings without having to invest in new equipment.

Furthermore, can closing machines are designed to be user-friendly and easy to operate. This means that companies can train their employees quickly and efficiently, reducing the risk of errors and downtime. By investing in a can closing machine, businesses can improve their overall efficiency and productivity, leading to increased profits and customer satisfaction.

In conclusion, can closing machines offer a wide range of advantages that can help businesses improve their efficiency and productivity. By automating the can closing process, companies can reduce the risk of product contamination and waste, increase their production output, and adapt to changing market demands. Additionally, these machines are versatile, user-friendly, and cost-effective, making them an ideal investment for companies looking to streamline their operations. Overall, a can closing machine is a valuable tool that can help businesses stay competitive in today’s fast-paced manufacturing industry.