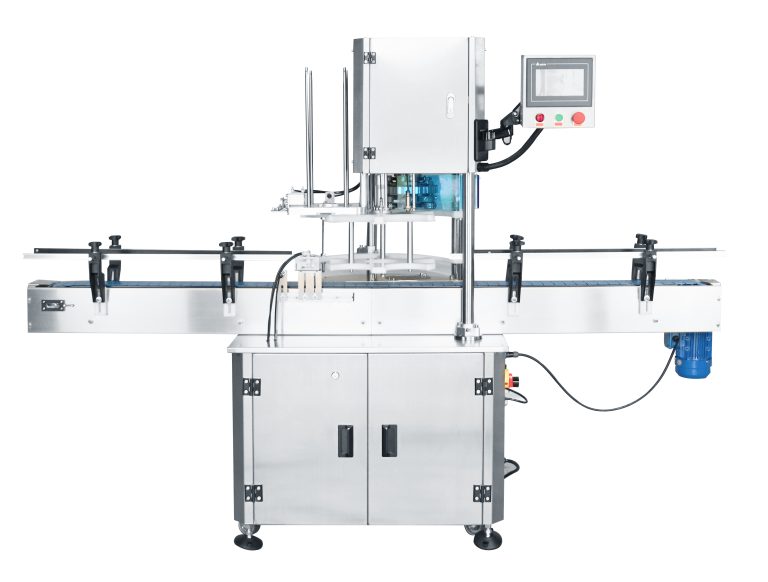

Enhanced Efficiency and Productivity

An automatic magnetic pump liquid filling machine operates at a rapid pace, allowing for a large number of containers to be filled in a short period. This significantly boosts production output and helps meet high demand efficiently.

Precise Filling Accuracy

These machines ensure exact and consistent filling volumes. This precision reduces product variation, minimizing waste and ensuring that each container is filled to the desired specification, which is crucial for maintaining product quality.

Reduced Labor Costs

With an automatic filling process, the need for manual labor is greatly reduced. This not only saves on wages but also frees up workers to focus on more complex or value-added tasks within the production line.

Minimal Maintenance Requirements

The design of automatic magnetic pump liquid filling machines is often durable and reliable. They have fewer moving parts and are less prone to breakdowns, resulting in lower maintenance costs and less downtime for repairs.

Versatility and Adaptability

These machines can handle a wide range of liquid viscosities and container sizes. They can be easily adjusted and programmed to accommodate different product specifications and packaging requirements, providing flexibility for businesses with diverse product lines.

In conclusion, the use of an automatic magnetic pump liquid filling machine offers multiple benefits that contribute to improved production processes, cost savings, and increased competitiveness in the market.