In the world of coffee packaging, the coffee powder vacuum can sealer with nitrogen gas is a cutting-edge solution that takes the preservation of coffee to a new level. This advanced equipment is specifically designed to safeguard the quality and flavor of coffee powder.

One of the primary benefits of this sealer is its vacuum sealing feature. By removing the air from the can, it slows down the oxidation process that can deteriorate the coffee’s aroma and taste. This ensures that the coffee powder retains its rich and complex flavors for a longer time.

The addition of nitrogen gas is another game-changer. Nitrogen helps to displace the oxygen, creating an inert environment that further protects the coffee from spoilage. It also helps to maintain the coffee’s texture and prevents it from becoming stale.

The precision and consistency of the sealing process are remarkable. Every can is sealed tightly, preventing any leaks or air infiltration that could compromise the quality of the coffee powder inside. This ensures that each cup of coffee brewed from the sealed can is as delicious as the first.

The sealer is designed to handle different can sizes and shapes, offering flexibility to coffee producers and packagers. It can adapt to various production volumes, making it suitable for both small-scale artisanal coffee roasters and large industrial operations.

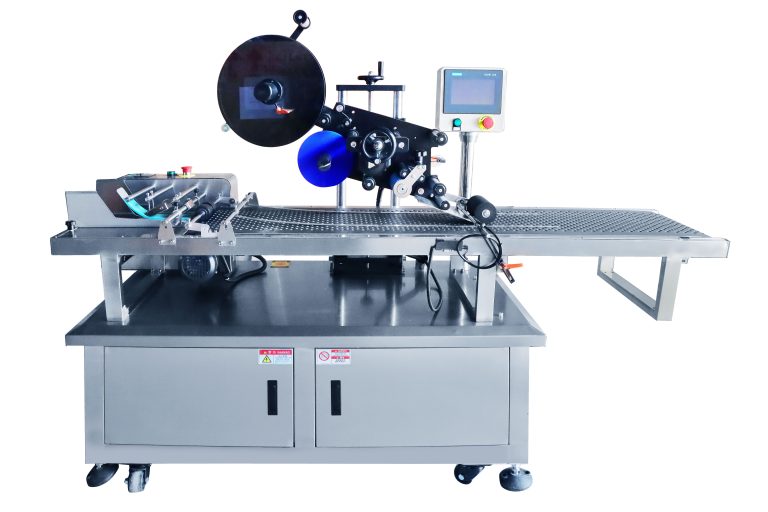

The equipment is often equipped with advanced control systems that allow for easy operation and monitoring. Operators can adjust the settings to optimize the sealing process based on the specific characteristics of the coffee powder.

Maintenance of the coffee powder vacuum can sealer with nitrogen gas is relatively straightforward. Regular cleaning and servicing of key components ensure its reliable performance and longevity.

In conclusion, the coffee powder vacuum can sealer with nitrogen gas is an essential tool for the coffee industry. It plays a crucial role in delivering high-quality, fresh-tasting coffee to consumers and enhancing the reputation of coffee brands.

Stay tuned to our blogs for more in-depth looks at the latest developments in coffee packaging technology!