It seems we can’t find what you’re looking for. Perhaps searching can help.

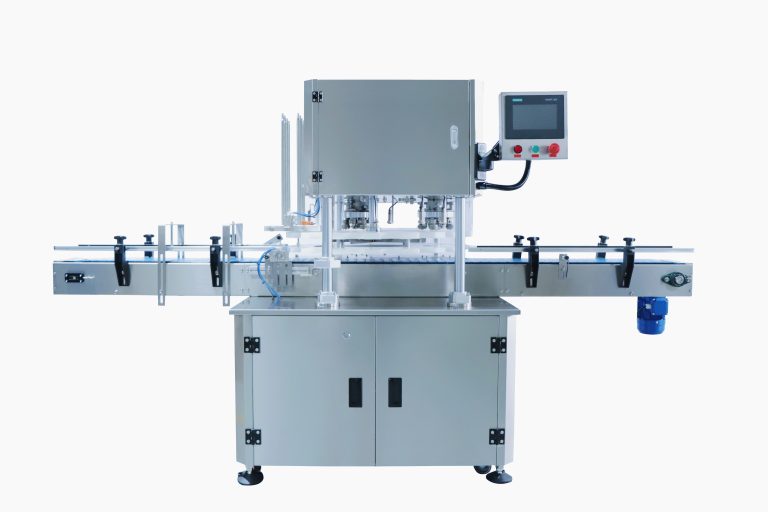

What is a Can Sealer? A Comprehensive Guide

Benefits of Using a Can Sealer for Home Canning Home canning is a popular method of preserving food that has been practiced for centuries. It allows individuals to store fruits, vegetables, and other perishable items for extended periods of time, ensuring that they have access to fresh, nutritious foods year-round….